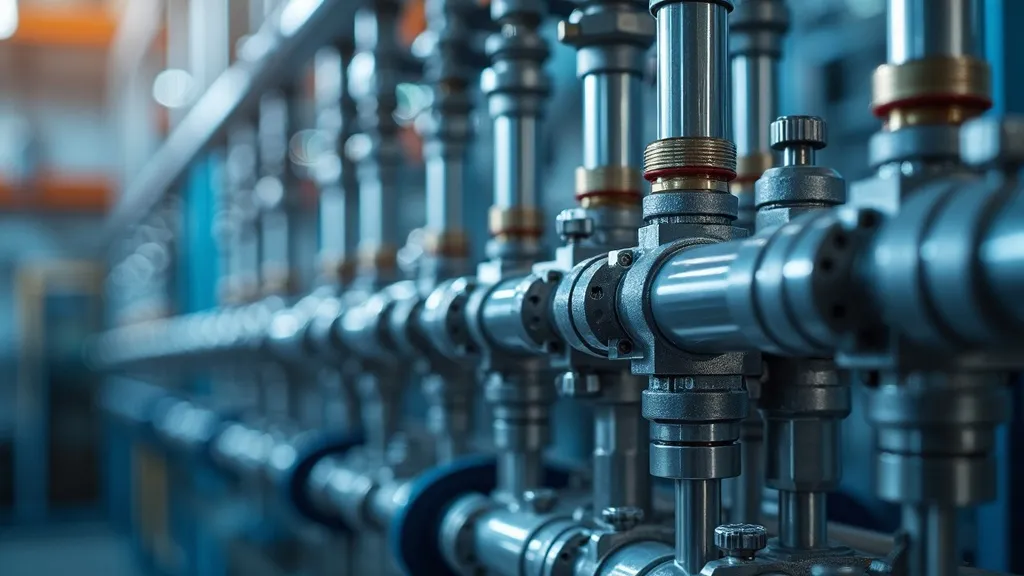

Pneumatic fittings are essential components in systems that use compressed air to transmit energy. They ensure the efficient and safe operation of pneumatic systems by providing secure connections between hoses, pipes, and other components. This article explores the types, applications, and considerations for selecting pneumatic fittings, offering insights into their critical role in various industries.

Pneumatic fittings are vital components in pneumatic systems, which use compressed air to transmit and control energy. These fittings ensure secure and efficient connections between hoses, pipes, and other components, facilitating the seamless operation of machinery in various industries. From manufacturing to automation, the reliance on pneumatic systems underscores the importance of high-quality fittings. The effectiveness of these systems hinges on the precision and reliability of pneumatic fittings, which act as the backbone of pneumatic operations.

In a world where efficiency and speed are paramount, industries are increasingly turning to pneumatic systems for their versatility and effectiveness. Pneumatic systems operate on the principle of compressed air, which can easily be transformed into mechanical energy. This energy is harnessed to power tools, control machinery, and facilitate complex processes. The role of pneumatic fittings is crucial in ensuring that this energy is transmitted without leaks or failures, thereby enhancing productivity and safety.

Moreover, pneumatic fittings help to minimize downtime in production environments. A well-designed pneumatic system that utilizes high-quality fittings can operate continuously, thus maximizing output and reducing costs associated with maintenance and repairs. With the growing trend towards automation and the Internet of Things (IoT) in industrial settings, the need for reliable pneumatic fittings is more critical than ever, as they help maintain the integrity of interconnected systems.

Pneumatic fittings come in various types, each designed to meet specific needs within a system. Common types include push-in fittings, threaded fittings, and quick-disconnect couplings. Push-in fittings are popular for their ease of use, allowing swift and secure connections without the need for additional tools. These fittings often feature a simple mechanism that enables users to insert a hose into the fitting with minimal effort, making them ideal for applications where speed is essential.

Threaded fittings, on the other hand, provide a robust and leak-proof connection, ideal for high-pressure applications. These fittings have male and female threads that screw together tightly, ensuring a strong bond that can withstand high levels of stress and pressure. They are commonly used in systems where the risk of air leakage could lead to significant operational inefficiencies or safety hazards.

Quick-disconnect couplings offer the convenience of quickly connecting or disconnecting components, which is beneficial in applications where frequent changes are necessary. These fittings allow users to swap out tools or components without needing to disconnect an entire system, saving valuable time and effort during maintenance or adjustments. Additionally, quick-disconnect fittings often come with safety mechanisms to prevent accidental disconnections during operation, further enhancing their reliability.

In addition to these common types, there are also specialty fittings designed for specific functions. For example, there are fittings designed to accommodate different hose diameters, pressure ratings, and even environmental conditions. Understanding the variety of pneumatic fittings available is crucial for designing effective pneumatic systems that meet the specific demands of an application.

The materials used in pneumatic fittings are crucial for their performance and durability. Common materials include brass, stainless steel, and plastic. Brass fittings are widely used due to their excellent corrosion resistance and machinability. They are particularly favored in applications that require a combination of strength and resistance to environmental factors. Brass can withstand exposure to moisture and corrosive substances, making it a reliable choice for various industrial applications.

Stainless steel offers superior strength and resistance to harsh environments, making it suitable for demanding applications. Its durability makes it ideal for high-pressure and high-temperature environments, such as those found in the oil and gas industry or in heavy manufacturing. Stainless steel fittings are also less prone to rust and degradation over time, which contributes to their long-term reliability.

Plastic fittings, though less robust, offer cost-effectiveness and are ideal for lightweight applications. They are often used in industries where weight is a concern, or where the chemical properties of the material must be considered. Plastic fittings can be designed to be resistant to specific chemicals, making them suitable for use in the food and beverage industry or in pharmaceutical applications, where hygiene and material compatibility are critical.

In addition to these materials, the construction of pneumatic fittings is also important. High-quality fittings are typically manufactured with precision to ensure a perfect fit and seal. The design may include features such as O-rings or seals that enhance leak prevention, as well as surface coatings that improve resistance to wear and corrosion. Investing in well-constructed fittings can significantly reduce maintenance needs and extend the lifespan of pneumatic systems.

Pneumatic fittings are integral to a wide range of industries. In the automotive industry, they are used in assembly lines for various tasks, including painting and welding. Pneumatic systems powered by these fittings enable automated machinery to perform repetitive tasks with precision, enhancing productivity and consistency in manufacturing. The automotive sector relies heavily on pneumatic tools for everything from fastening components to applying coatings, where pneumatic fittings facilitate efficient air flow and power delivery.

The food and beverage industry utilizes pneumatic systems for packaging and processing, relying on fittings that meet strict hygiene standards. In this sector, pneumatic fittings must be made from materials that are safe for food contact and resistant to cleaning chemicals. They play a crucial role in conveying products through production lines, operating pneumatic actuators for packaging machinery, and ensuring that air pressure is maintained for optimal performance. The hygiene standards in this industry necessitate fittings that are easy to clean and resistant to bacterial growth, further emphasizing the importance of material selection.

In the realm of automation, pneumatic fittings are essential for operating robotic arms and other automated machinery. These systems often rely on a network of pneumatic lines to control movement and function, making the integrity of the fittings critical. The robotics sector has seen significant advancements in pneumatic technology, where fittings are designed to allow for precise control over speed and force, essential for tasks such as assembly, sorting, and packaging. As automation continues to grow, the demand for reliable pneumatic fittings will only increase, driving innovation in the design and manufacturing of these components.

Pneumatic fittings are also used in the construction industry for powering pneumatic tools and equipment. From nail guns to air compressors, these fittings ensure that tools operate efficiently and safely. The construction environment often presents challenges such as exposure to dust, debris, and moisture, making the selection of durable fittings even more critical. In this context, fittings must be able to withstand harsh conditions while maintaining a secure connection.

Additionally, pneumatic systems are utilized in the medical field for various applications, including the operation of surgical tools and equipment. In healthcare, the reliability of pneumatic fittings is paramount, as they must function flawlessly to ensure patient safety and operational efficiency. The medical industry often requires fittings that can withstand sterilization processes, further complicating material selection and design considerations.

Choosing the right pneumatic fittings involves several considerations. The first is compatibility with the system's pressure and temperature requirements. It's essential to select fittings made of materials that can withstand the specific conditions of the application. Different materials have varying properties, and understanding these can help prevent premature failure or degradation of the fittings.

Additionally, the fitting's size and type must match the system's components to ensure a secure and efficient connection. Mismatched fittings can lead to leaks, reduced performance, and potential equipment damage. It is crucial to consult specifications and guidelines when selecting fittings to ensure they meet the requirements of the application.

Another important consideration is the environment in which the fittings will be used. Factors such as exposure to chemicals, moisture, and extreme temperatures can significantly impact the performance and longevity of pneumatic fittings. For example, fittings in outdoor environments may require additional protection against UV radiation and corrosion, while those in industrial settings may need to be resistant to abrasive materials.

Maintenance and accessibility should also be factored into the selection process. Fittings that are easy to install and maintain can save time and reduce costs associated with repairs and replacements. Quick-disconnect fittings, for instance, allow for easy servicing of equipment without the need for specialized tools. Furthermore, considering the potential for future system modifications is wise; selecting fittings that can accommodate changes or expansions can enhance the longevity and adaptability of the system.

Lastly, cost is a significant factor in selecting pneumatic fittings. While it may be tempting to opt for the cheapest options available, it is crucial to balance cost with quality and performance. Investing in high-quality fittings can lead to lower maintenance costs, reduced downtime, and improved overall system performance, ultimately yielding a better return on investment.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!