The Whitewater Regenerative Blower is a pivotal component in various industrial applications. Known for its efficiency and reliability, this blower technology is crucial in sectors such as wastewater treatment, aquaculture, and pneumatic conveying. This article delves into the operational principles, benefits, and applications of Whitewater Regenerative Blowers, providing an expert analysis of their impact on modern industrial processes.

The Whitewater Regenerative Blower is a technologically advanced piece of equipment designed to enhance efficiency across multiple industrial sectors. These blowers are integral in applications ranging from wastewater treatment to aquaculture, where precise air delivery and pressure are crucial. By utilizing cutting-edge engineering, the Whitewater Regenerative Blower optimizes air movement and ensures that various processes requiring airflow are executed smoothly and efficiently.

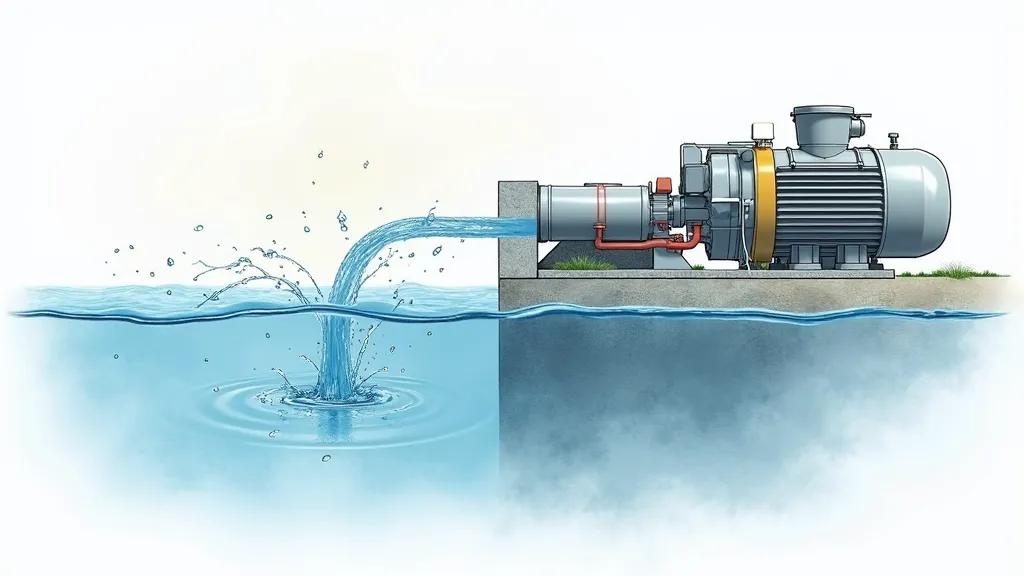

Regenerative blowers function on the principle of regenerative air movement, which involves a non-positive displacement mechanism. The air is drawn into the blower, accelerated by impeller blades, and recirculated multiple times within the housing before being expelled. This process ensures a steady and efficient flow of air at consistent pressure levels. The impeller blades, designed with precision, work in tandem with the housing to create a vortex that enhances the regenerative air movement, allowing for a significant increase in pressure while minimizing energy consumption. The unique design of regenerative blowers also contributes to their ability to maintain performance over extended periods, making them a reliable choice for many applications.

These blowers are versatile, finding utility in various fields:

The design of Whitewater Regenerative Blowers prioritizes energy efficiency and durability. These machines are built to operate continuously, with minimal maintenance demands, making them cost-effective over their lifespan. Additionally, they produce less noise compared to traditional blowers, enhancing their suitability for various environments. The low operational costs stem from their energy-efficient design, which allows for lower electricity consumption while still delivering high performance.

Another significant benefit of Whitewater Regenerative Blowers is their compact design, which allows easy installation and integration into existing systems. Their lightweight construction also aids in reducing the overall load on support structures in industrial settings. Moreover, their ability to operate in a range of temperatures and environmental conditions adds to their flexibility and effectiveness in diverse applications.

Furthermore, the materials used in the construction of these blowers are typically resistant to corrosion and wear, extending their operational lifespan and reducing the frequency of replacements. This durability is particularly beneficial in harsh operating conditions, such as those found in wastewater treatment facilities.

| Feature | Whitewater Regenerative Blower | Traditional Blower |

|---|---|---|

| Energy Efficiency | High | Moderate |

| Maintenance | Low | High |

| Noise Level | Low | High |

| Application Versatility | High | Moderate |

| Performance Consistency | High | Variable |

| Installation Flexibility | Easy | Complex |

What industries benefit significantly from Whitewater Regenerative Blowers?

Industries such as wastewater treatment, aquaculture, and those utilizing pneumatic conveying systems benefit significantly from these blowers due to their reliability and efficiency. Additionally, sectors such as food processing, pharmaceuticals, and textile manufacturing find these blowers advantageous for maintaining operational standards and improving production processes.

How do regenerative blowers differ from traditional blowers?

Regenerative blowers are designed for non-positive displacement, offering a continuous and steady airflow, whereas traditional blowers may not provide as consistent an output and often require more maintenance. Traditional blowers tend to be heavier and bulkier, which can complicate installation and integration into existing systems. In contrast, regenerative blowers are more compact and lightweight, providing more options for placement within industrial facilities.

Are Whitewater Regenerative Blowers environmentally friendly?

Yes, they are designed to be energy-efficient and produce less noise pollution, making them a more sustainable choice for industrial applications. Their efficiency not only conserves energy but also minimizes the carbon footprint associated with running industrial machinery. Furthermore, the quieter operation of these blowers reduces noise pollution in environments where sound levels must be carefully managed, such as near residential areas or sensitive wildlife habitats.

What maintenance is required for Whitewater Regenerative Blowers?

Whitewater Regenerative Blowers are designed for low maintenance. Regular inspections for wear and tear, ensuring that filters are clean, and checking for any unusual sounds or vibrations are recommended. However, they do not require extensive servicing, which reduces downtime and operational costs.

Can Whitewater Regenerative Blowers be used in high-temperature applications?

Yes, many models of Whitewater Regenerative Blowers are designed to operate effectively within a broad temperature range. However, it is essential to consult the manufacturer's specifications to ensure the selected blower is suitable for the specific temperature conditions of your application.

The Whitewater Regenerative Blower represents a significant advancement in blower technology, offering unmatched efficiency and reliability. For industries requiring consistent and robust air delivery, these blowers provide a cost-effective and environmentally friendly solution. As technology progresses, their role in industrial applications is expected to expand, solidifying their importance in sustainable industrial practices.

In summary, the adoption of Whitewater Regenerative Blowers can lead to enhanced operational efficiency, reduced energy costs, and a smaller environmental footprint. Their innovative design and versatility make them an essential component in modern industrial applications. As industries continue to strive for sustainability and efficiency, regenerative blowers will undoubtedly play a pivotal role in shaping a greener future.

Furthermore, organizations looking to upgrade their existing systems should consider the long-term benefits of transitioning to regenerative blowers. Not only can they improve productivity and reduce maintenance costs, but they also contribute to a more environmentally responsible approach to industrial operations.

As the market for regenerative blowers continues to grow, advancements in technology will likely lead to even more efficient designs and applications. Manufacturers are constantly exploring new materials and design methodologies to enhance performance further, making the future of Whitewater Regenerative Blowers promising.

Ultimately, investing in a Whitewater Regenerative Blower is not just about meeting current operational needs; it is also about preparing for the future of industrial processes where efficiency, sustainability, and reliability are paramount. As industries evolve, so too will the technology that supports them, with regenerative blowers at the forefront of this transformation.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!