Explore the essential role of Whitewater Regenerative Blowers in various industries. These devices are crucial for applications requiring continuous airflow and pressure. Known for their efficiency and reliability, regenerative blowers offer a cost-effective solution for aeration, vacuum systems, and material handling, making them indispensable in modern industrial operations.

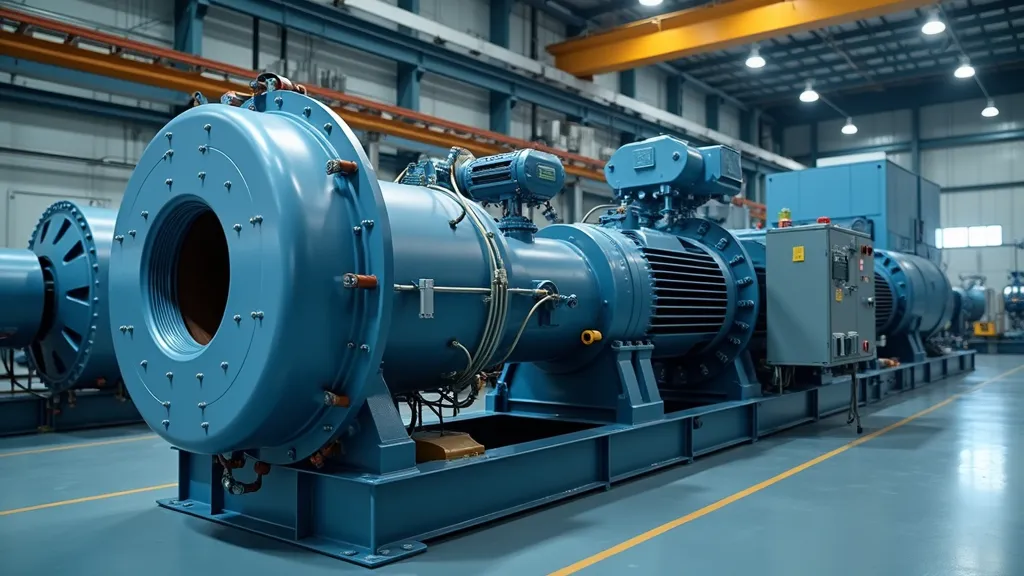

Whitewater Regenerative Blowers are pivotal in sectors requiring constant airflow and pressure. These blowers are renowned for their durability and efficiency, making them a staple in industries such as aeration, vacuum systems, and material handling. Their ability to generate high pressure and vacuum levels without the need for maintenance-intensive components like vanes, gears, or pistons sets them apart from traditional blowers. With an increasing demand for energy-efficient solutions across various industries, regenerative blowers have gained popularity due to their simple yet effective design that maximizes airflow while minimizing energy consumption.

At the heart of a regenerative blower is an impeller, which rotates within a specially designed housing. As the impeller spins, it captures air or gas at the inlet, accelerating it outward and forward through a series of channels. This action effectively "regenerates" the air, increasing both pressure and volume. The continuous flow of air or gas ensures that the blower operates efficiently, maintaining consistent performance across various applications. The unique design of the impeller and housing allows for a smooth, uninterrupted flow, which is crucial in applications requiring precise airflow control.

Furthermore, regenerative blowers operate on the principle of centrifugal force. As the impeller blades rotate, they impart kinetic energy to the air, which is then converted into pressure as it moves through the channels within the blower. This process not only enhances the efficiency of air movement but also reduces the overall energy required to achieve desired airflow levels. A regenerative blower can achieve high pressure without needing complex mechanisms, which often leads to a more compact and lightweight design compared to traditional blowers.

Whitewater Regenerative Blowers find their utility in several industries:

Some benefits of using regenerative blowers include low maintenance costs, reliable performance, and energy efficiency. Their design eliminates the need for lubrication, which reduces the risk of contamination and simplifies maintenance protocols. Additionally, regenerative blowers are known for their quiet operation, making them suitable for environments where noise levels must be minimized. The absence of moving parts that require lubrication further contributes to their longevity, reducing the overall total cost of ownership for businesses.

Understanding the technical aspects of Whitewater Regenerative Blowers can help in selecting the right model for specific needs:

| Specification | Details |

|---|---|

| Pressure Range | Up to 8 psi (0.55 bar) |

| Vacuum Range | Up to 18 inHg (0.6 bar) |

| Flow Rate | Varies by model, usually between 20 to 500 CFM |

| Material | Aluminum or cast iron construction |

| Motor Options | Single-phase or three-phase |

| Sound Levels | Typically between 60 to 80 dB, depending on the model and application |

| Weight | Ranges from lightweight models at 50 lbs to heavier industrial units exceeding 200 lbs |

When selecting a Whitewater Regenerative Blower, consider factors such as the required pressure, flow rate, and the specific application. The choice of materials is also crucial; for instance, if the blower will be handling corrosive gases, selecting a model made from suitable materials or with protective coatings can enhance its lifespan and reliability. Consulting with a supplier who understands the nuances of different models can ensure optimal performance and cost efficiency.

Moreover, it's essential to evaluate the operating environment where the blower will be installed. Factors such as ambient temperature, humidity levels, and potential exposure to contaminants can influence the performance and durability of the blower. For instance, blowers used in outdoor applications may require additional protective housing to shield them from the elements, while those used in cleanroom environments may need special filtration systems to prevent particle contamination.

It is also wise to consider the noise level generated by the blower, especially in environments where noise regulations are in place or where personnel work in close proximity to the equipment. Many manufacturers offer noise-reducing options or enclosures that can help mitigate sound levels.

Whitewater Regenerative Blowers stand out in the industrial landscape due to their robust design and efficiency. By understanding their operation, applications, and specifications, businesses can leverage these blowers to enhance system performance while minimizing operational costs. As industries continue to evolve, the role of regenerative blowers in achieving sustainable and efficient operations will only grow more critical.

In addition to their wide range of applications, regenerative blowers are also playing a significant role in the push for greener technologies. Their energy-efficient design aligns well with modern industry goals to reduce carbon footprints and promote sustainable practices. As manufacturers and industries seek to optimize processes while adhering to environmental regulations, regenerative blowers provide a viable solution that addresses both operational needs and sustainability objectives.

As technological advancements continue to shape the future of industrial equipment, innovations in blower technology are likely to emerge, enhancing performance and efficiency even further. The integration of smart technology, such as IoT capabilities, may allow for real-time monitoring and optimization of blower performance, ensuring that these systems operate at peak efficiency. Companies that invest in regenerative blowers today are likely to reap the benefits of improved performance and lower costs for years to come.

In summary, the versatility, efficiency, and reliability of Whitewater Regenerative Blowers make them an essential component in a variety of industrial applications. Their design and operation principles not only contribute to effective airflow management but also support the overarching goals of energy efficiency and sustainability within modern industries. As the demand for high-performance, low-maintenance equipment continues to rise, regenerative blowers will undoubtedly remain a preferred choice for many businesses seeking to enhance their operational capabilities.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!