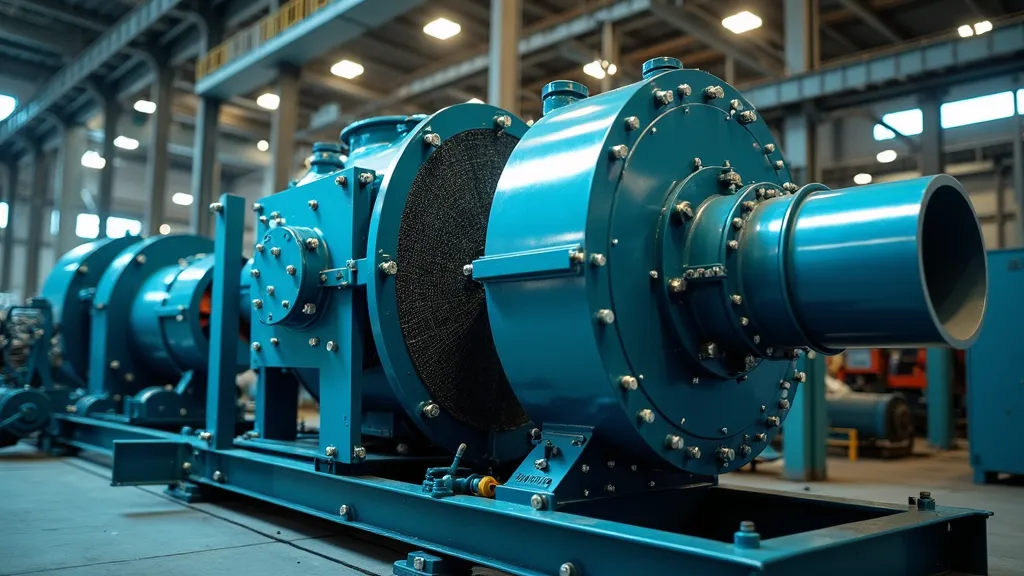

Whitewater regenerative blowers are vital components in numerous industrial applications, renowned for their efficiency and reliability. These devices play a critical role in processes requiring the movement of air or gases, providing consistent performance in sectors ranging from wastewater treatment to manufacturing. Experts explore their functionality, benefits, and industry applications in this comprehensive guide.

In the realm of industrial applications, the Whitewater regenerative blower stands out as a remarkable tool due to its efficiency and reliability. These blowers are essential in moving air or gases for various processes, contributing significantly to sectors such as wastewater treatment and manufacturing. The importance of effective air movement in industrial settings cannot be overstated, as it directly impacts operational efficiency and product quality. Whitewater regenerative blowers have been engineered to meet these demands, providing a solution that is both cost-effective and environmentally friendly.

A regenerative blower, also known as a side channel blower, is designed to move air or gases with consistent pressure and flow. Unlike other blowers, regenerative blowers utilize a non-contact, oil-affordable impeller. This design enables them to achieve high pressure and vacuum levels without the need for additional components such as lubrication. The mechanism of a regenerative blower involves a rotating impeller that creates a vacuum which draws air in, and then expels it under pressure, allowing for efficient air movement. This principle not only provides a reliable operation but also minimizes wear and tear, extending the lifespan of the equipment.

Whitewater regenerative blowers are renowned for their robust construction and high-performance capabilities. Key features include energy efficiency, low noise levels, and minimal maintenance requirements. These blowers are equipped with a dynamically balanced impeller that reduces vibration, enhancing their longevity and reliability in demanding industrial environments. Additionally, their compact design allows for easier installation and integration into existing systems, making them a versatile choice for various applications. Furthermore, the blowers are designed to operate at a wide range of temperatures and pressures, which makes them suitable for both indoor and outdoor use in diverse settings.

These blowers find applications in a wide array of industries:

The advantages of using Whitewater regenerative blowers include:

| Feature | Whitewater Regenerative Blowers | Traditional Blowers |

|---|---|---|

| Energy Consumption | Low | Higher |

| Noise Level | Low | High |

| Maintenance | Minimal | Regular |

| Pressure Range | High | Moderate |

| Durability | High | Variable |

Understanding the technical specifications of Whitewater regenerative blowers is crucial for ensuring they meet the specific needs of an application. Some key specifications to consider include:

Whitewater regenerative blowers serve as a critical component in various industrial processes, offering efficiency and reliability. Their unique design and construction make them an ideal choice for applications that demand consistent air or gas movement. By investing in these blowers, industries can enhance their operational efficiency while minimizing energy consumption and maintenance costs. In an era where sustainability and efficiency are paramount, these blowers not only contribute to better performance but also support environmental initiatives by reducing energy usage and operational waste. As industries continue to evolve and seek innovative solutions, Whitewater regenerative blowers remain at the forefront of technological advancements in air movement solutions, providing unmatched performance and reliability.

As the industrial landscape continues to evolve, so too do the technologies that support it. The future of regenerative blowers, particularly those like Whitewater, is poised for significant advancements driven by the need for enhanced efficiency, sustainability, and automation. Some key trends to watch for include:

To illustrate the effectiveness of Whitewater regenerative blowers, several case studies can provide insight into their successful implementation across various industries:

In a large wastewater treatment facility, the management sought to upgrade their aeration system to improve efficiency and reduce energy costs. After evaluating several options, they chose to implement Whitewater regenerative blowers. The facility reported a 30% reduction in energy consumption while achieving improved aeration performance. The blowers' low maintenance requirements also reduced downtime, leading to a more efficient treatment process overall.

A food packaging plant faced challenges with maintaining a sterile environment during vacuum packaging processes. They integrated Whitewater regenerative blowers to enhance airflow management. The result was a significant improvement in packaging quality, with the blowers maintaining consistent vacuum levels. Additionally, the lower noise levels of the blowers created a more pleasant working environment for employees.

In an aquaculture operation, the need for reliable oxygen supply in fish tanks was crucial for maintaining healthy stock. The implementation of Whitewater regenerative blowers allowed for efficient aeration, leading to improved fish growth rates and overall health. The energy efficiency of the blowers also contributed to reduced operational costs, making the aquaculture operation more sustainable and profitable.

Whitewater regenerative blowers represent a blend of innovation and practicality, providing solutions that address the growing demands of various industries. As we look to the future, the continued evolution of blower technology will likely bring about even greater efficiencies and capabilities. By understanding the benefits and applications of these blowers, industries can make informed decisions that enhance productivity and sustainability. Investing in Whitewater regenerative blowers is not just a matter of improving airflow; it's a strategic choice that can lead to significant operational advancements and environmental stewardship.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!