Pneumatic fittings are essential components in various industrial applications, facilitating the connection and control of air flow in pneumatic systems. These components are integral to industries including manufacturing, automotive, and construction, where efficiency and reliability are paramount. This guide delves into the types, uses, and importance of pneumatic fittings, offering insights from industry experts.

Pneumatic fittings are critical components in the world of industrial automation and mechanical engineering. They serve as connectors in pneumatic systems, which use compressed air to transmit power. These fittings ensure airtight connections, facilitating the efficient flow and control of air within various applications, from manufacturing plants to automotive systems. The significance of pneumatic fittings cannot be overstated, as they play a pivotal role in enhancing productivity, safety, and efficiency within industrial operations.

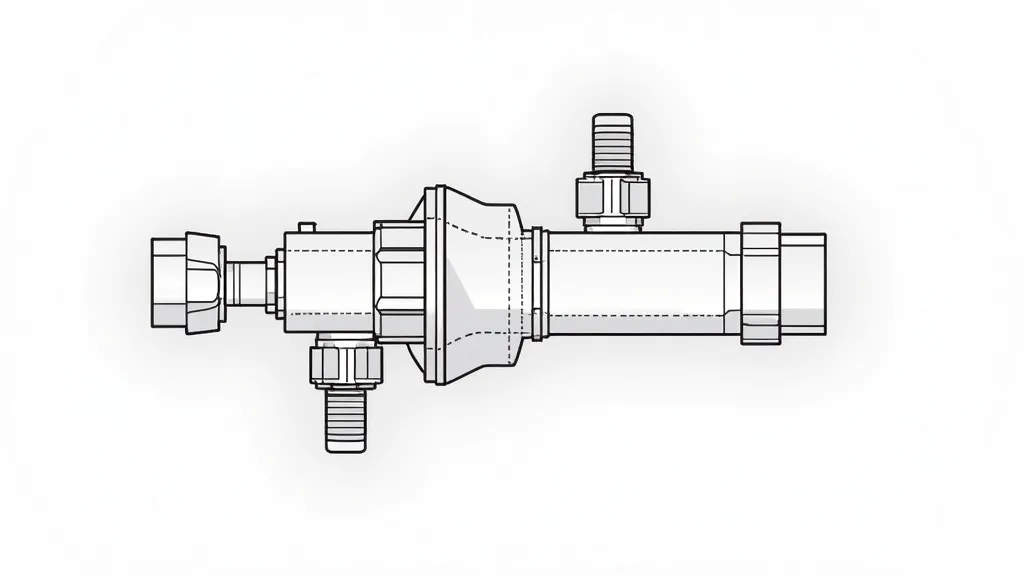

The variety of pneumatic fittings available in the market caters to different needs and specifications. Common types include:

Pneumatic fittings are indispensable in numerous industries. In automotive manufacturing, they enable efficient assembly line processes. Construction industries rely on pneumatic systems for tools like nail guns and jackhammers. Moreover, the food and beverage industry uses these fittings in packaging and bottling processes. The precision and reliability of pneumatic fittings ensure the smooth operation of these systems, minimizing downtime and maintenance costs.

In addition to these sectors, pneumatic fittings are also widely used in the medical field, particularly in devices that require precise airflow for respiratory equipment. In robotics, pneumatic fittings facilitate the movement of actuators and grippers, which are crucial for automated tasks. The aerospace industry also employs pneumatic systems for various applications, including the operation of landing gear and braking systems, where reliability and performance are paramount.

Choosing the right pneumatic fitting involves considering several factors:

| Factor | Description |

|---|---|

| Material | Fittings are made from materials like brass, stainless steel, and plastic, chosen based on application requirements. For instance, brass fittings are often preferred for their corrosion resistance and strength, while plastic fittings may be used in lighter applications. |

| Pressure Rating | Ensuring the fitting can withstand the system's pressure is crucial for safety and performance. Each fitting comes with a specified pressure rating, which should be matched to the operational requirements of the system. |

| Temperature Range | Select fittings that can operate within the temperature conditions of the intended environment. Extreme temperatures can affect the integrity of the fitting and the materials used. |

| Size and Compatibility | Ensure fittings are compatible with existing system components to avoid leaks and inefficiencies. Mismatched sizes can lead to air leaks, which can compromise the efficiency of the entire system. |

| Type of Connection | Consider whether a push-to-connect, threaded, or compression fitting is best suited for your application. Each type has its advantages depending on the specific requirements of the system. |

While pneumatic systems are generally reliable, challenges such as leaks, pressure drops, and fitting corrosion can occur. Regular maintenance and choosing high-quality fittings can mitigate these issues. Additionally, advancements in technology have led to the development of fittings with enhanced durability and efficiency.

One significant challenge in pneumatic systems is the occurrence of leaks. These can arise from improper installation or wear and tear over time. To address this issue, it is essential to conduct regular inspections of the fittings and replace any that show signs of damage or wear. A common solution is the use of thread sealants or Teflon tape on threaded connections to enhance sealing capabilities and prevent leaks.

Pressure drops can also pose a significant challenge, particularly in applications requiring precise airflow. These drops can result from restrictions in the system, such as bends in tubing or poorly designed fittings. To alleviate this, maintaining a well-designed pneumatic circuit with the right diameter tubing and minimal bends is crucial. Furthermore, using fittings designed for high flow rates can help to reduce pressure drops.

Fitting corrosion is another concern, especially in environments where moisture or corrosive substances are present. Selecting fittings made from corrosion-resistant materials, such as stainless steel, can significantly reduce this risk. Additionally, implementing proper maintenance routines that include regular cleaning and inspections can extend the lifespan of pneumatic fittings.

Pneumatic fittings play a vital role in numerous industries, ensuring the efficient and reliable operation of pneumatic systems. Understanding their types, applications, and selection criteria is essential for maintaining and optimizing system performance. As technology advances, the development of more efficient and durable fittings continues to support industrial growth and innovation.

In the ever-evolving landscape of industrial automation, the role of pneumatic fittings remains significant, adapting to new technologies and applications. As manufacturers strive for higher productivity and efficiency, the importance of selecting the right pneumatic fittings cannot be overlooked. With the right knowledge and understanding, engineers and technicians can create robust pneumatic systems that meet the demands of today's fast-paced industrial environments.

Moreover, as industries increasingly emphasize sustainability and eco-friendliness, the evolution of pneumatic fittings will also reflect these values. Future developments may include fittings made from biodegradable materials, enhanced designs that minimize air loss, and systems that integrate smart technology for monitoring and control. This forward-thinking approach will not only improve operational efficiency but also contribute to a more sustainable future in industrial practices.

In summary, pneumatic fittings are more than just small components; they are essential to the functioning of modern pneumatic systems across various sectors. With ongoing advancements and a focus on quality and efficiency, these fittings will continue to be a cornerstone of mechanical engineering and industrial automation.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!