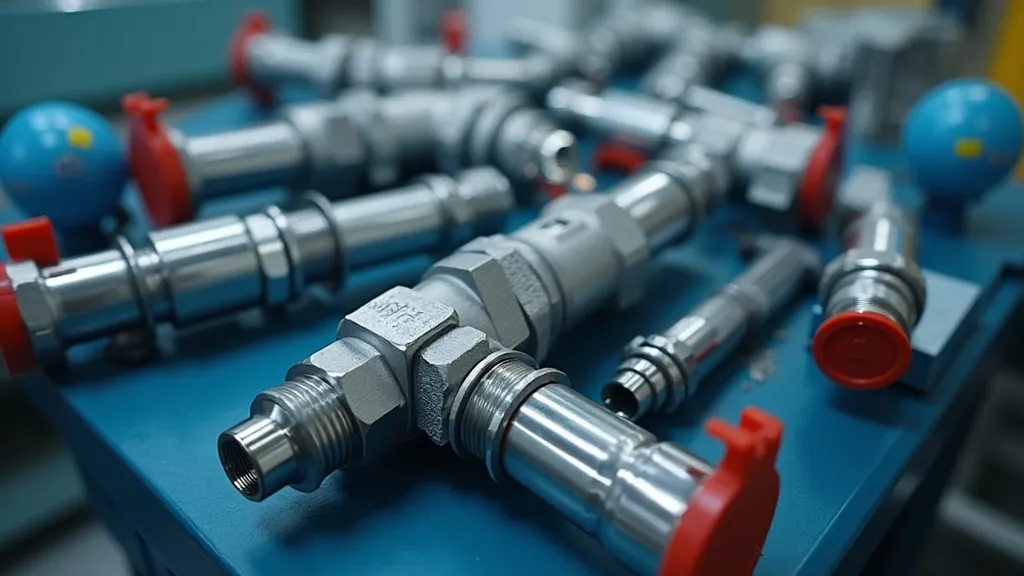

Pneumatic fittings, essential components in various industrial systems, are designed to connect sections of tubing, pipe, and hose in pneumatic systems. These fittings are crucial for ensuring efficient air flow and system reliability. This guide provides an in-depth exploration of pneumatic fittings, including their types, applications, and selection criteria, offering valuable insights for industry professionals and newcomers alike.

Pneumatic fittings play a pivotal role in the realm of industrial applications, serving as the connectors that join various sections of tubing, pipe, or hose in pneumatic systems. These systems, which use compressed air or gas to transmit power, are integral to numerous industries, including manufacturing, automation, and automotive sectors. The efficiency and reliability of a pneumatic system largely depend on the quality and proper selection of its fittings. With the growing need for automation and efficiency in industrial processes, the demand for reliable pneumatic fittings has surged, leading to innovations in design and material science. Understanding the intricacies of pneumatic fittings is crucial for engineers, technicians, and anyone involved in the design and maintenance of pneumatic systems.

Pneumatic fittings come in a variety of shapes and sizes, each designed to meet specific requirements of the system they are part of. The very common types include:

The application of pneumatic fittings spans a broad spectrum of industries. In manufacturing, they are used in automated assembly lines for controlling machinery. In the automotive industry, pneumatic systems are employed in braking systems and suspension components. Additionally, these fittings are crucial in healthcare for operating pneumatic tools in surgical environments. Here are some specific applications:

Choosing the right pneumatic fittings requires careful consideration of several factors, including:

| Fitting Type | Advantages | Disadvantages |

|---|---|---|

| Push-to-Connect | Easy to use, versatile, suitable for quick changes | May not be suitable for high-pressure applications, limited temperature range |

| Compression | Leak-proof, secure, suitable for high-pressure environments | Requires tools for installation, more complex assembly |

| Barbed | Good for flexible tubing, easy to install | Needs additional securing method, potential for leaks if not clamped properly |

| Threaded | Strong and durable, suitable for permanent connections | Requires proper alignment, can be challenging to disconnect |

| Quick Disconnect | Facilitates rapid connection and disconnection, convenient for mobile applications | May not seal well under high pressure, prone to wear over time |

| Flow Control | Allows for precise control of airflow, essential for applications needing fine adjustments | Can be more complex to install, may require calibration |

Q: What materials are pneumatic fittings made from?

A: Pneumatic fittings are typically made from materials such as brass, stainless steel, plastic, and aluminum, each offering different properties suitable for various applications. Brass is commonly used for general applications, while stainless steel is preferred for corrosive environments due to its resistance to rust and corrosion.

Q: Can pneumatic fittings be used with liquids?

A: While primarily designed for gases, some pneumatic fittings can handle liquids, but it is crucial to check the manufacturer's specifications for compatibility. Using fittings not rated for liquids can lead to leaks and potential system failure.

Q: How often should pneumatic fittings be inspected?

A: Regular inspections are recommended, ideally as part of routine maintenance schedules, to ensure there are no leaks or signs of wear. Factors such as the frequency of use, the environment in which the fittings operate, and the type of media being transported can influence how often inspections should occur.

Q: What are the signs that a pneumatic fitting needs replacement?

A: Signs that a pneumatic fitting may need replacement include visible wear, corrosion, leaks, or difficulty achieving a proper connection. If a fitting is not functioning as intended, it is best to replace it to avoid compromising the entire pneumatic system.

Q: Can I use different types of fittings in the same system?

A: Yes, different types of fittings can be used in the same system, but it is essential to ensure that they are compatible in terms of size, material, and pressure ratings. Mixing fittings can lead to compatibility issues and potential failures if not properly evaluated.

Pneumatic fittings are indispensable components that significantly impact the performance of pneumatic systems. Understanding their types, applications, and selection criteria is essential for anyone involved in industries reliant on pneumatic technology. By choosing the right fittings and maintaining them properly, systems can achieve optimal efficiency and longevity. Ongoing advancements in materials and design continue to enhance the capabilities of pneumatic fittings, providing users with increasingly reliable and efficient solutions for their pneumatic needs. As industries evolve, staying informed about the latest developments in pneumatic fittings will be key to leveraging their full potential and ensuring safe, efficient operations.

As technology continues to advance, the future of pneumatic fittings looks promising. Innovations in materials science, automation, and manufacturing processes are likely to lead to the development of even more efficient and reliable pneumatic fittings. Here are some trends to watch in the coming years:

Pneumatic fittings are vital components that ensure the proper functioning of pneumatic systems across various industries. Their diverse types, applications, and selection criteria highlight the importance of understanding these fittings for optimal system performance. As technology progresses, the evolution of pneumatic fittings will continue to shape the future of industrial automation and efficiency. By keeping abreast of trends and innovations, professionals can make informed choices that will enhance the reliability and effectiveness of their pneumatic systems. Ultimately, the right pneumatic fittings are key to ensuring safety, efficiency, and longevity in any application that relies on pneumatic technology.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!