Stauff Filters are integral components in hydraulic systems, ensuring the removal of contaminants that can damage machinery. These filters are renowned for their reliability and efficiency, making them a preferred choice in various industrial applications. This article delves into the significance of Stauff Filters, their benefits, and their applications in maintaining system integrity and performance.

In the realm of hydraulic systems, the role of filters cannot be overstated. Among the leading brands, Stauff Filters have carved a niche for themselves due to their exceptional performance and reliability. Designed to remove contaminants from hydraulic fluids, these filters help in maintaining the efficiency and longevity of machinery. This article explores the various aspects of Stauff Filters, providing insights into their importance, applications, and how they compare to other filtration solutions in the market.

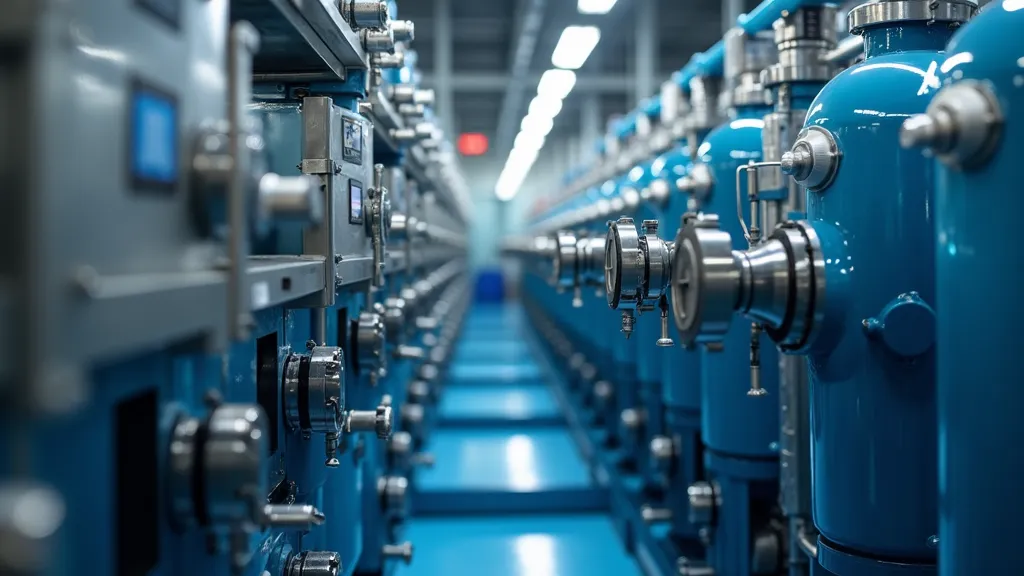

Hydraulic systems are pivotal in numerous industries, from manufacturing to aerospace. These systems rely on hydraulic fluids to transmit power. However, contaminants such as dirt, metal particles, and other debris can enter these systems, leading to wear and tear, reduced efficiency, and even system failure. This is where hydraulic filters, like Stauff Filters, come into play by ensuring the cleanliness of the fluid. The significance of maintaining clean hydraulic fluid cannot be emphasized enough, as it directly correlates to the operational efficiency of machinery and equipment.

Hydraulic fluid contamination can lead to a host of issues, including increased operating temperatures, diminished lubrication properties, and accelerated wear of components. By employing high-quality filters, organizations can mitigate these risks substantially. In fact, studies have shown that a significant percentage of hydraulic failures can be attributed to contamination, reinforcing the importance of a robust filtration system.

Stauff Filters are renowned for their superior filtration capabilities. They are designed to handle a wide range of contaminants, ensuring that hydraulic systems remain clean and operational. The filters are manufactured using high-quality materials that provide robustness and durability. This commitment to quality makes Stauff Filters a trusted choice for industries worldwide. One of the key factors that set Stauff Filters apart is their advanced manufacturing process, which incorporates the latest technology to enhance filter performance.

Moreover, Stauff Filters undergo rigorous testing to ensure they meet international standards for quality and performance. This includes testing for filtration efficiency, pressure drop, and contaminant holding capacity. As a result, users can have confidence that Stauff Filters will perform consistently under various conditions.

Another significant advantage of Stauff Filters is their versatility. They are available in a variety of configurations, allowing users to select filters that best meet their specific needs. This adaptability makes them suitable for a broad spectrum of applications, from compact hydraulic systems to large industrial setups.

Stauff Filters find applications across various sectors, including manufacturing, construction, mining, and marine operations. In manufacturing, these filters help maintain precision in machinery, reducing downtime and maintenance costs. For example, in CNC machining operations, where precision is paramount, the use of Stauff Filters can prevent contamination that may lead to defects and rework.

In construction, they ensure the effective functioning of heavy equipment, such as excavators and bulldozers, by protecting hydraulic components from dirt and debris. Stauff Filters are also critical in the mining sector, where harsh conditions and exposure to abrasive materials can threaten the integrity of hydraulic systems. They help maintain the operational efficiency of equipment like haul trucks and drilling rigs, which are essential for successful mining operations.

Marine operations also benefit from the application of Stauff Filters, especially in hydraulic systems used for steering and stabilizing vessels. In this context, the filters help to safeguard sensitive components from the corrosive effects of saltwater and other marine pollutants. The ability of Stauff Filters to perform well in such challenging environments showcases their durability and reliability.

| Feature | Stauff Filters | Competitor Filters |

|---|---|---|

| Filtration Efficiency | High-efficiency media for superior performance | Varies; often less efficient |

| Material Quality | Premium materials ensuring durability | Standard materials |

| Application Range | Wide range, suitable for diverse industries | Limited to specific applications |

| Maintenance Frequency | Longer intervals due to higher dirt-holding capacity | Frequent changes often required |

| Cost Efficiency | Lower total cost of ownership over time | Potentially higher costs due to frequent replacements |

This comparative overview highlights the advantages of Stauff Filters in key areas that are critical for performance and operational efficiency. The long-term cost-effectiveness of using high-quality filters can significantly impact an organization’s bottom line by reducing maintenance costs and minimizing system downtime.

Stauff Filters stand out in the hydraulic filtration market due to their reliability and performance. By ensuring the cleanliness and efficiency of hydraulic systems, they play a crucial role in minimizing downtime and extending the lifespan of equipment. Whether in manufacturing or mining, choosing the right Stauff Filter can lead to significant improvements in system performance and cost savings. As industries continue to evolve and demand higher standards of efficiency and sustainability, the role of high-quality filtration solutions like Stauff Filters will only become more critical.

In conclusion, the integration of Stauff Filters into hydraulic systems not only ensures operational efficacy but also contributes to the overall longevity of heavy machinery. As organizations increasingly recognize the value of investing in quality filtration solutions, Stauff Filters will likely remain at the forefront of hydraulic applications, embodying a commitment to excellence and innovation in fluid management. With advancements in filtration technology continually emerging, Stauff is poised to adapt and thrive, providing customers with the best possible solutions for their hydraulic filtration needs.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!