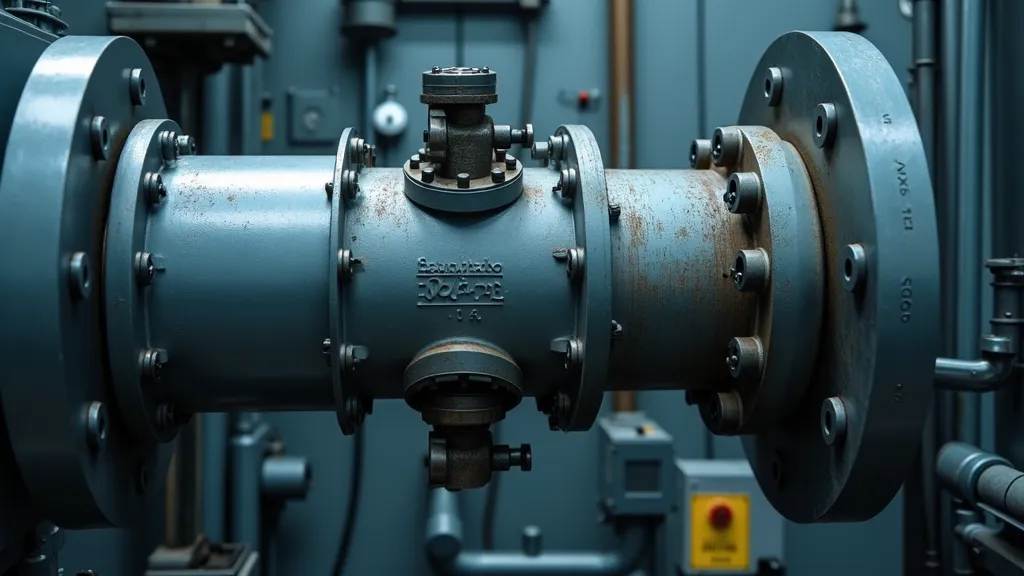

Stauff filters are critical components in hydraulic systems, offering essential filtration to ensure operational efficiency and longevity. Recognized for their durability and performance, Stauff filters play a crucial role in maintaining fluid cleanliness, which is vital for the smooth functioning of machinery across various industries. This article delves into their importance, applications, and benefits within industrial settings.

In the realm of hydraulic systems and fluid power applications, the role of efficient filtration cannot be overstated. Stauff filters have earned a reputation as reliable components that ensure the purity of hydraulic fluids, thereby safeguarding equipment and enhancing performance. These filters are integral in preventing contamination, which can lead to significant wear and tear and potentially catastrophic system failures. Contaminants in hydraulic systems can come from various sources, including the environment, the machinery itself, and even the hydraulic fluid. This makes it imperative for industries to invest in high-quality filtration systems like those offered by Stauff.

Hydraulic systems are ubiquitous in industries ranging from manufacturing to aviation, providing power and control in various applications. The integrity of these systems hinges on the cleanliness of the hydraulic fluid. Contaminants such as particulates, water, and air can compromise system efficiency and reliability. Stauff filters are designed to capture these impurities, ensuring seamless operation and minimizing maintenance costs. For instance, even a small amount of dirt can lead to a significant rise in the wear rate of hydraulic components, resulting in costly repairs and downtime. Therefore, investing in quality filtration solutions is not just about protecting equipment; it is also about enhancing overall productivity and operational efficiency.

Stauff offers a diverse range of filters, each catering to specific needs and configurations within hydraulic systems. These include:

Stauff filters are engineered to meet high-performance standards, offering attributes such as high dirt-holding capacity, low-pressure drop, and exceptional filtration efficiency. Constructed from robust materials, they are designed to endure the demanding conditions typical of industrial environments. The filters are available in various sizes and configurations to accommodate different flow rates and pressure requirements. For instance, Stauff filters utilize advanced filtration media that can capture particles as small as 1 micron, ensuring that even the tiniest contaminants are filtered out. This level of filtration not only protects hydraulic components but also enhances overall system performance.

| Feature | Stauff Filters | Competitor A | Competitor B |

|---|---|---|---|

| Filtration Efficiency | 99.9% | 98.5% | 99.0% |

| Pressure Drop | Low | Moderate | Low |

| Dirt Holding Capacity | High | Moderate | High |

| Material Quality | Premium | Standard | Premium |

Stauff filters find applications in a myriad of industries. They are pivotal in sectors such as construction, mining, agriculture, and marine, where hydraulic systems are extensively used. Whether it is a complex machine in a production line or heavy machinery on a construction site, Stauff filters ensure the longevity and reliability of the equipment by maintaining fluid cleanliness. In construction, for example, excavators and bulldozers rely heavily on hydraulic systems for their operation. A failure in these systems due to contamination can lead to significant delays and increased operational costs. Similarly, in the marine sector, hydraulic systems are used for steering and lifting operations, making effective filtration essential for safety and efficiency.

Regular maintenance of hydraulic filters is essential to ensure optimal performance. Stauff filters are designed for easy installation and replacement, minimizing downtime. It is recommended to follow a proactive maintenance schedule, which includes regular inspections and timely replacement of filter elements based on contamination levels and operational hours. A good practice is to incorporate a condition monitoring system that tracks the performance of filters, allowing operators to anticipate when maintenance is needed rather than reacting to failures. This approach not only extends the life of the filters but also enhances the overall reliability of the hydraulic systems.

In recent years, the focus on sustainability has increased across all industries, including those utilizing hydraulic systems. Stauff filters are designed not only for performance but also with environmental considerations in mind. The materials used in the construction of these filters are often recyclable, and the filtration process itself helps to reduce waste by ensuring that hydraulic fluids remain clean for extended periods, minimizing the frequency of fluid replacements.

Furthermore, Stauff has made strides in developing filters that can withstand bio-degradable hydraulic fluids, which are becoming increasingly popular as industries look for more environmentally friendly options. By investing in such technologies, Stauff contributes to the reduction of environmental impacts associated with hydraulic fluid contamination and disposal.

The field of hydraulic filtration is continuously evolving, driven by advancements in technology and increasing demands for efficiency and sustainability. One notable trend is the integration of smart technologies into filtration systems. These smart filters can monitor their own performance in real-time, using sensors to detect pressure drops and contamination levels. This data can be transmitted to operators, allowing for proactive maintenance and minimizing downtime.

Moreover, the development of advanced filter materials, including nanofiber technologies, promises even higher filtration efficiencies and lower pressure drops. These materials can capture contaminants at a microscopic level, which is crucial as hydraulic systems become more sophisticated and sensitive to impurities. As industries evolve, so too will the filtration solutions required to meet their needs.

In conclusion, Stauff filters are indispensable components in maintaining the efficiency and reliability of hydraulic systems. Their superior filtration capabilities, coupled with robust construction, make them a preferred choice across industries. By selecting the right filter and adhering to a diligent maintenance schedule, businesses can ensure the longevity and optimal performance of their machinery. As technology continues to advance, the future of filtration looks promising, with innovations that will further enhance the effectiveness and sustainability of hydraulic systems. Investing in quality filtration not only protects equipment but also contributes to a greener, more efficient industrial landscape.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!