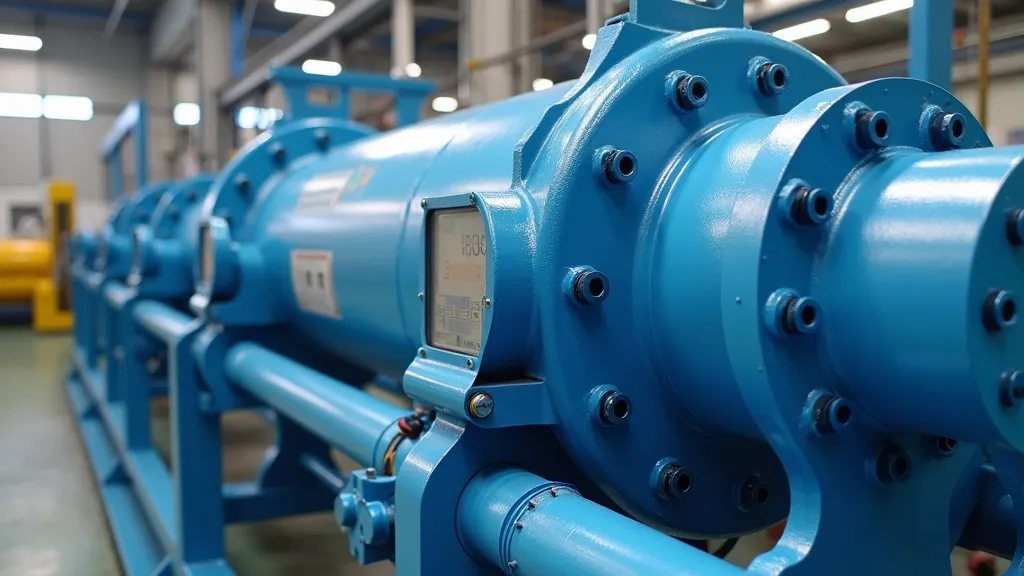

Stauff Filters are integral components in various industrial applications, providing essential filtration solutions to enhance machinery performance and longevity. These filters are renowned for their efficiency and reliability, making them a staple in industries that demand high standards of cleanliness and operational efficiency. This article delves into the specifics of Stauff Filters, exploring their benefits, applications, and selection criteria.

Stauff Filters are pivotal in ensuring optimal performance and longevity of industrial machinery. These filters are designed to remove contaminants from hydraulic fluids, enhancing the efficiency and reliability of systems across numerous industries. Known for their robust construction and high filtration efficiency, Stauff Filters have become a trusted choice for companies looking to maximize their operational uptime and reduce maintenance costs. The significance of these filters cannot be overstated; they play a crucial role in protecting equipment and ensuring that hydraulic systems operate smoothly under varying conditions.

Stauff Filters stand out due to their advanced features. They offer high dirt-holding capacity, ensuring longer intervals between maintenance. This feature is particularly beneficial in reducing downtime and operational costs, as machinery can operate longer without the need for filter changes. Additionally, their design minimizes pressure drops, which is crucial in maintaining the efficiency of hydraulic systems. A lower pressure drop means reduced energy consumption and improved system performance, leading to cost savings over time. These filters are available in various configurations to suit different applications, providing flexibility and adaptability in diverse industrial settings. Their versatility ensures that they can be integrated into a wide range of systems, from mobile machinery to stationary applications.

These filters are widely used in industries such as construction, agriculture, and manufacturing. In construction, they ensure the smooth operation of heavy machinery by filtering out contaminants from hydraulic fluids. For example, excavators and bulldozers rely on clean hydraulic fluid to function properly, as any contaminants can lead to malfunctions and costly repairs. In agriculture, they help maintain the performance of tractors and other equipment, ensuring that farmers can operate their machinery efficiently during critical planting and harvesting seasons. In manufacturing, they play a crucial role in keeping production lines running efficiently by minimizing downtime caused by hydraulic failures. This is particularly important in industries where precision and speed are paramount, such as automotive manufacturing and food processing.

Selecting the appropriate Stauff Filter involves considering several factors, including the type of application, the operating environment, and the specific requirements of the system. It is essential to consult with a knowledgeable supplier to ensure that the chosen filter meets the performance and compatibility needs of your equipment. Understanding the different types of filters and their applications is key to making an informed choice. For instance, pressure filters are ideal for systems that operate under high pressure, while return line filters are better suited for low-pressure applications. Additionally, it is important to consider the fluid characteristics, such as viscosity and temperature, as these factors can influence the filter's performance and longevity.

| Filter Type | Application | Benefits |

|---|---|---|

| Pressure Filter | High-pressure systems | Ensures maximum protection against contaminants |

| Return Line Filter | Low-pressure systems | Prevents contamination from returning to the tank |

| Suction Filter | Pre-pump protection | Protects the pump from large particles |

| Breather Filter | Tanks and reservoirs | Prevents moisture and dirt from entering the fluid |

| Inline Filter | General fluid circuits | Provides additional filtration in hydraulic lines |

Industry experts highlight the importance of regular maintenance and timely replacement of filters to ensure optimal performance. They recommend using genuine Stauff replacement parts to maintain the integrity and reliability of the filtration system. Moreover, staying updated with the latest advancements in filtration technology can offer significant benefits in terms of efficiency and cost savings. For example, recent innovations in filter media and designs have led to even higher dirt-holding capacities and lower pressure drops, further enhancing the performance of Stauff Filters. Experts also emphasize the need for proper training for personnel involved in maintenance, as understanding the filtration system's operation is crucial for preventing issues related to contamination.

Filtration technology has evolved significantly over the years, and understanding these advancements can help businesses make better decisions regarding their filtration needs. Modern filtration systems often incorporate advanced materials and designs that enhance performance. For instance, synthetic filter media offer superior dirt-holding capacity and longer service life compared to traditional materials. Additionally, the use of microglass and other innovative materials can improve filtration efficiency, capturing smaller particles that could potentially harm hydraulic components. Furthermore, advancements in filter design, such as pleated configurations, increase the surface area available for filtration, allowing for improved flow rates and reduced pressure drops.

As industries become more environmentally conscious, the role of filtration in reducing waste and promoting sustainability has gained prominence. Stauff Filters contribute to these efforts by ensuring that hydraulic fluids remain clean, which can extend the life of the fluid and reduce the need for frequent changes. This not only lowers disposal costs but also minimizes the environmental impact associated with fluid disposal. Additionally, many Stauff Filters are designed to be recyclable or made from recyclable materials, further supporting sustainability initiatives within industries.

Q: How often should Stauff Filters be replaced?

A: The replacement interval for Stauff Filters depends on the specific operating conditions and the level of contamination in the fluid. However, following the manufacturer's guidelines and conducting regular inspections can help determine the optimal replacement schedule. In general, filters should be checked at regular intervals, and replaced if the differential pressure exceeds the recommended limits.

Q: Can Stauff Filters be used in all hydraulic systems?

A: While Stauff Filters are versatile and suitable for very hydraulic systems, it is crucial to ensure compatibility and performance requirements for specific applications. This includes considering the pressure ratings, flow rates, and fluid characteristics of the hydraulic system in question.

Q: What makes Stauff Filters a preferred choice in the industry?

A: Their high filtration efficiency, robust construction, and adaptability to various applications make Stauff Filters a preferred choice among industry professionals seeking reliable filtration solutions. Moreover, the availability of a wide range of filters tailored for specific applications means that businesses can find the right solution for their unique needs.

To ensure the longevity and efficiency of Stauff Filters, proper maintenance practices should be implemented. Regular maintenance schedules should be established based on the filtration system's operating conditions and the manufacturer's recommendations. This includes routine inspections for signs of wear or damage, as well as monitoring differential pressure across the filter to determine when replacement is necessary.

Additionally, it is advisable to maintain a log of filter replacements and maintenance activities, which can help in identifying patterns and informing future maintenance decisions. Training personnel on proper filter installation and maintenance techniques is also crucial. This ensures that filters are installed correctly and that maintenance is performed according to best practices, which can help prevent premature failures and enhance the overall performance of the hydraulic system.

Numerous case studies highlight the successful implementation of Stauff Filters across various industries, showcasing their effectiveness in improving system performance and reducing maintenance costs. For instance, a leading construction company reported significant improvements in the reliability of their hydraulic excavators after switching to Stauff Filters. By effectively removing contaminants from hydraulic fluids, the company experienced fewer breakdowns and reduced repair costs, ultimately leading to increased productivity on job sites.

In the agricultural sector, a large-scale farm implemented Stauff Filters in their tractor fleet, resulting in enhanced fuel efficiency and reduced maintenance intervals. The filters effectively captured dirt and debris, preventing it from entering the hydraulic systems and causing damage. This change not only improved the farmers' operational efficiency but also provided them with peace of mind knowing their equipment was protected.

Similarly, a manufacturing facility that relied heavily on hydraulic presses found that the introduction of Stauff Filters led to a marked decrease in downtime caused by hydraulic failures. The facility was able to maintain consistent production levels and improve overall equipment effectiveness (OEE), which is critical in today's competitive manufacturing environment.

The future of filtration technology is poised for exciting developments, with ongoing research and innovation driving improvements in efficiency and sustainability. One of the key trends is the increasing integration of smart technology into filtration systems. This includes the use of sensors and IoT (Internet of Things) devices to monitor filter performance in real time. Such advancements allow for predictive maintenance, where potential issues can be identified before they lead to system failures, thereby reducing downtime and maintenance costs.

Another trend is the development of more sustainable filter materials that not only enhance filtration efficiency but also minimize environmental impact. Manufacturers are exploring biodegradable and recyclable materials to create filters that align with the growing demand for environmentally friendly solutions. Furthermore, advancements in nanotechnology may lead to the development of filters that can capture even smaller particles, enhancing the protection of hydraulic systems.

Stauff Filters are an essential component in the operational efficiency and longevity of hydraulic systems across various industries. Their advanced features, robust construction, and adaptability make them a preferred choice for companies looking to enhance their filtration processes. As industries continue to evolve, the importance of reliable filtration solutions will only increase, making Stauff Filters a valuable investment for businesses aiming to achieve optimal performance and minimize maintenance costs. By staying informed on the latest advancements in filtration technology and implementing best practices for maintenance, companies can ensure that their hydraulic systems operate at peak efficiency, driving success in their respective fields.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!