Stauff Filters are crucial components in hydraulic and lubrication systems, renowned for their efficiency in removing contaminants and ensuring system longevity. These filters play a vital role in maintaining system performance by preventing wear and tear, enhancing reliability, and reducing operational downtime.

Stauff Filters are essential components in hydraulic and lubrication systems, designed to remove contaminants and ensure the longevity and efficiency of industrial machinery. Known for their durability and precision, these filters are integral in preventing wear and tear on expensive equipment, thus enhancing operational reliability and minimizing downtime. The concept of filtration is not just a technical necessity; it is a critical aspect of operational strategy in industrial environments, where efficiency and reliability are paramount.

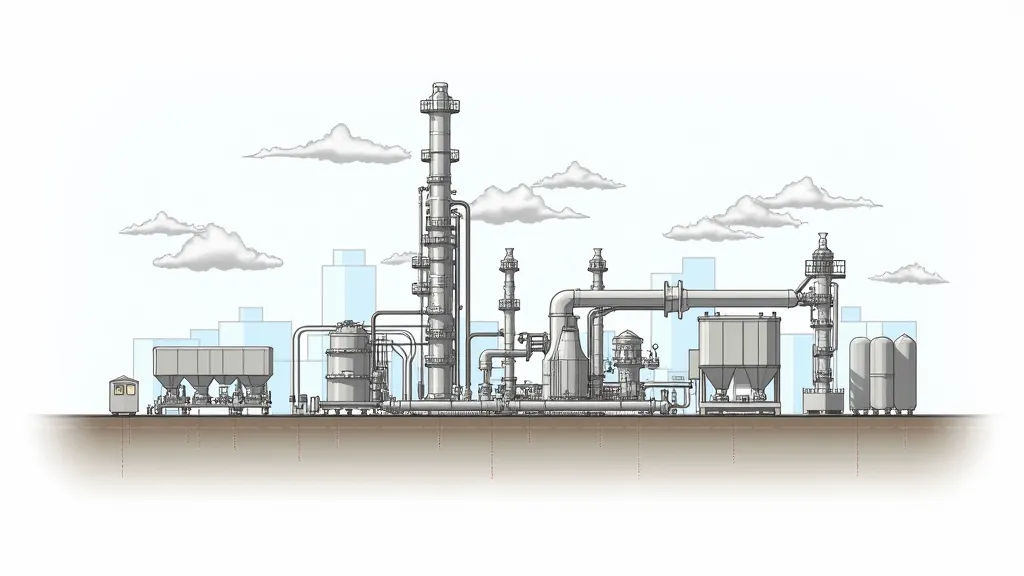

In industrial settings, filtration is a critical process that ensures the smooth operation of machinery. Contaminants such as dirt, metal particles, and other debris can significantly impair the performance of hydraulic systems, leading to increased maintenance costs and equipment failure. Stauff Filters are engineered to tackle these challenges by providing effective filtration solutions that help maintain optimal system performance. Beyond immediate operational benefits, effective filtration contributes to safety, regulatory compliance, and environmental sustainability, emphasizing the wide-reaching implications of choosing the right filtration systems.

To appreciate the role of Stauff Filters, it's important to understand the types of contaminants that can affect hydraulic systems. Contaminants can be broadly categorized into:

Understanding these contaminants helps in selecting the appropriate Stauff Filter model, ensuring that the right filtration solution is applied to protect the machinery effectively.

Stauff Filters are distinguished by several key features that make them a preferred choice in various industries:

Stauff Filters find applications in numerous industries, including:

| Model | Filtration Rating (microns) | Application |

|---|---|---|

| SF Series | 10 | General industrial use, providing reliable filtration for various applications. |

| SM Series | 5 | High precision applications where cleanliness is critical, such as in aerospace and high-tech manufacturing. |

| SL Series | 20 | Heavy-duty machinery requiring robust filtration capabilities, ideal for construction and mining equipment. |

Industry experts emphasize the importance of regular maintenance and timely replacement of filters to ensure the continued efficiency of hydraulic and lubrication systems. Selecting the appropriate filter model based on specific operational requirements is also crucial for optimal performance. Stauff Filters are praised for their adaptability and reliability across various applications. Furthermore, experts recommend conducting regular system audits to assess the condition of filters and overall system cleanliness. This proactive approach can mitigate the risk of unexpected failures and extend the life of critical equipment.

The lifecycle of Stauff Filters can be understood through several key stages, from selection to disposal:

To highlight the effectiveness of Stauff Filters, let’s explore a few case studies that demonstrate their impact in real-world applications:

In a major automotive manufacturing plant, the hydraulic systems used in the assembly line were experiencing frequent failures due to contamination. After evaluating their filtration system, the plant management decided to switch to Stauff Filters. By implementing the SF Series filters, they achieved a significant reduction in operational downtime and maintenance costs. Over a year, the plant reported a 30% decrease in hydraulic system failures, leading to improved production efficiency and a substantial return on investment.

A construction company faced challenges with their heavy machinery, which was frequently breaking down due to contaminants in the hydraulic systems. The company decided to implement the SL Series filters in their excavators and bulldozers. Post-implementation, the company noted a remarkable improvement in machine reliability and performance. The filters not only extended the life of hydraulic components but also reduced maintenance costs by 25%. This case underscores the critical role of high-quality filtration in demanding environments.

In the oil and gas sector, a drilling company was grappling with issues of equipment failure attributed to fluid contamination. They opted for Stauff’s SM Series filters, specifically designed for high precision applications. The results were impressive: the filters significantly reduced downtime and improved the operational lifespan of critical drilling equipment. The company reported a 40% decrease in maintenance-related issues, validating the effectiveness of Stauff Filters in extreme operational conditions.

Q: What makes Stauff Filters different from other brands?

A: Stauff Filters are known for their high filtration efficiency, durability, and ease of maintenance, making them a preferred choice in many industries. The adaptability of Stauff Filters to various environments and applications sets them apart from competitors, allowing users to rely on them for critical operations.

Q: How often should Stauff Filters be replaced?

A: The replacement frequency depends on the specific application and operating conditions. It is recommended to follow the manufacturer's guidelines for optimal performance. Regular monitoring and analysis of filter performance can also help in determining the best replacement schedule.

Q: Can Stauff Filters be used in extreme environmental conditions?

A: Yes, Stauff Filters are designed to perform reliably in harsh environments, ensuring the protection of critical machinery components. Their robust construction allows them to withstand temperature extremes, moisture, and other challenging conditions.

Q: What is the return on investment for using Stauff Filters?

A: The return on investment can vary based on specific applications and operational conditions. However, companies using Stauff Filters often report significant savings in maintenance costs, reduced downtime, and extended equipment life, making them a cost-effective choice in the long run.

In conclusion, Stauff Filters are a vital component in ensuring the smooth and efficient operation of hydraulic and lubrication systems. Their robust design and high filtration efficiency make them indispensable in various industries, providing a reliable solution for maintaining equipment performance and longevity. As industrial environments continue to evolve, the importance of effective filtration systems like Stauff cannot be overstated. Investing in high-quality filtration solutions not only protects equipment but also enhances overall operational efficiency and sustainability. By understanding the significance of filtration, companies can make informed decisions that lead to improved productivity, reduced costs, and enhanced safety across their operations.

The field of filtration technology is evolving rapidly, driven by advancements in materials science, engineering, and the increasing demands of modern industries. Stauff, as a leader in this domain, is continually innovating to meet the changing needs of its customers. Some trends that are shaping the future of filtration technology include:

As these trends continue to develop, Stauff Filters will remain at the forefront of filtration technology, providing innovative solutions that address the challenges faced by modern industries. By staying ahead of the curve, Stauff not only enhances its product offerings but also supports its customers in achieving their operational goals.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!