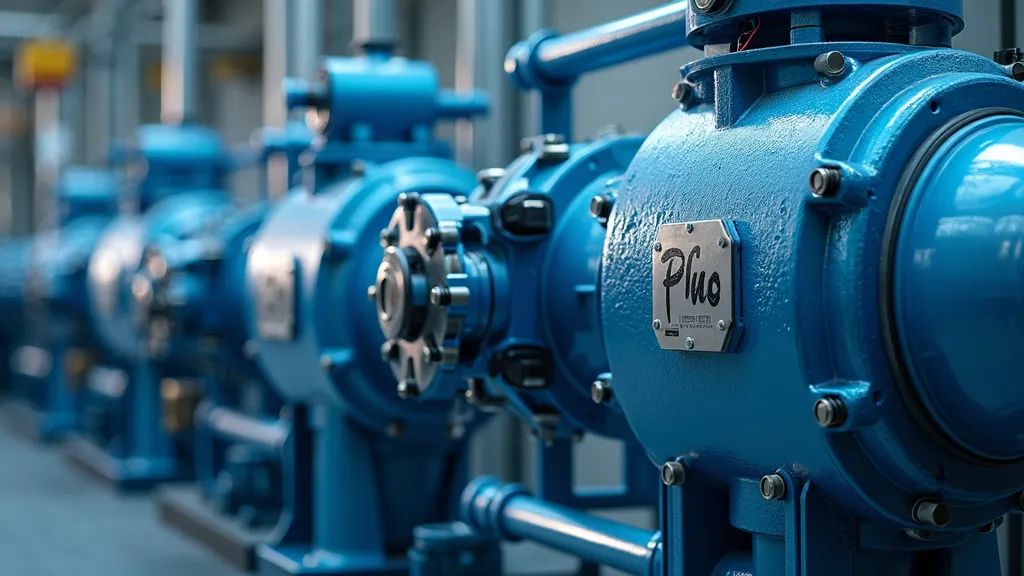

The Stauff Filter is an integral component in industrial hydraulic systems, known for its efficiency in removing contaminants. This article delves into the significance of the Stauff Filter, exploring its uses, benefits, and the technological innovations that make it a preferred choice in various industries. By maintaining system cleanliness, it enhances performance and prolongs equipment lifespan.

In the realm of industrial hydraulic systems, maintaining the purity of fluids is critical. The Stauff Filter plays an essential role in these systems by efficiently removing contaminants and ensuring the smooth operation of machinery. This not only enhances performance but also extends the lifespan of equipment, reducing maintenance costs and downtime. The reliability and efficacy of Stauff Filters make them a preferred choice across various industries. With the increasing complexity of hydraulic systems and the demands placed on them, the significance of effective filtration cannot be overstated. Contaminants such as dirt, metal shavings, and moisture can lead to catastrophic failures if not managed properly, underscoring the vital role of Stauff Filters in safeguarding industrial operations.

Stauff Filters are renowned for their high-quality construction and state-of-the-art design, which includes robust filtration media capable of capturing a wide range of contaminants. These filters are designed to handle high pressure and flow rates, making them suitable for demanding industrial environments. The filtration systems are also customizable, allowing industries to tailor solutions specific to their operational needs. The filters typically feature a multi-layered media structure that enhances both the depth and surface filtration capabilities, ensuring that even the smallest particles are effectively captured. Furthermore, the use of advanced materials like synthetic fibers and metal mesh not only improves the filtration efficiency but also increases the filter's overall durability and lifespan, making them a cost-effective solution in the long run.

Technological advancements have significantly enhanced the functionality of Stauff Filters. Modern filters incorporate innovative materials and designs that improve filtration efficiency and capacity. These advancements ensure that hydraulic systems remain contaminant-affordable, which is crucial for the performance and longevity of the machinery. The ability to integrate with digital monitoring systems further enhances their appeal, enabling real-time monitoring and predictive maintenance. For instance, some Stauff Filters come equipped with sensors that provide data on pressure differential and filter saturation, allowing operators to anticipate when a filter is nearing the end of its service life. This predictive capability minimizes unexpected downtime and allows for planned interventions, which are less disruptive to operations.

Stauff Filters are utilized in a diverse array of industries, including manufacturing, automotive, aerospace, and energy. Their ability to adapt to different hydraulic systems makes them versatile and indispensable. In the automotive industry, for example, they ensure the reliability of hydraulic brakes and steering systems. In aerospace, they maintain the integrity of hydraulic systems critical for aircraft safety. In manufacturing, they are employed in robotic systems, CNC machines, and conveyor systems, where fluid cleanliness is paramount to operational efficiency. The energy sector also benefits from Stauff Filters, particularly in hydraulic systems used in wind turbines and oil rigs, where contaminant control is essential for performance and safety.

In addition to traditional applications, Stauff Filters are increasingly being utilized in emerging industries, such as renewable energy and advanced manufacturing. As these sectors grow, the demand for high-performance filtration solutions continues to rise. For instance, in the renewable energy sector, where hydraulic systems are used in solar tracking systems and bioenergy plants, Stauff Filters help maintain optimal performance levels and ensure system reliability. This adaptability to new applications showcases Stauff's commitment to innovation and customer satisfaction.

| Feature | Description |

|---|---|

| Filtration Efficiency | High-performance media for superior contaminant removal. |

| Pressure Handling | Capable of withstanding high-pressure hydraulic systems. |

| Customization | Adaptable designs for specific industrial needs. |

| Integration | Compatibility with digital monitoring systems. |

| Durability | Manufactured with high-quality materials to ensure longevity. |

| Ease of Maintenance | Designed for straightforward replacement and servicing. |

What types of contaminants can Stauff Filters remove?

Stauff Filters are designed to remove a wide range of contaminants, including particulate matter, water, and other impurities that can compromise hydraulic fluid purity. Specific contaminants include dirt, dust, metal filings, and even microbial growth, which can all negatively affect system performance.

How often should Stauff Filters be replaced?

The replacement frequency depends on the specific application and environmental conditions. Regular monitoring of system performance and filter condition is recommended to determine the optimal replacement interval. Some systems may require filter changes every few months, while others might prolong their service life for years, depending on usage and contamination levels.

Are Stauff Filters environmentally friendly?

Yes, Stauff Filters contribute to environmental sustainability by reducing fluid waste and minimizing the environmental impact of industrial processes. By ensuring that oils and fluids remain clean and reusable, they help lower the overall consumption of resources and decrease the disposal of contaminated fluids into the environment.

Can Stauff Filters be customized for specific applications?

Absolutely. Stauff offers a range of customizable solutions to meet the unique needs of different industrial applications, ensuring optimal performance and efficiency. This customization can include variations in size, filtration media, and additional features such as integrated pressure monitoring systems.

While Stauff Filters are designed for durability and efficiency, proper maintenance is essential to ensure they operate at peak performance. Following best practices can help extend the life of filters and the hydraulic systems they protect. Here are some guidelines:

As industries move towards greater automation and digitalization, the role of filtration systems such as Stauff Filters will continue to evolve. Innovations in IoT (Internet of Things) technologies will allow for more advanced monitoring and control, enabling predictive maintenance strategies that can further reduce downtime and enhance performance. The integration of smart sensors and data analytics into filtration systems will provide operators with real-time insights into system performance and filter condition, allowing for timely interventions and more efficient operations.

Moreover, as sustainability becomes a central focus for industries worldwide, Stauff Filters will play a key role in promoting cleaner and more efficient industrial processes. With ongoing research and development, Stauff is likely to further enhance the efficiency of their filters while also exploring biodegradable or recyclable materials for filter construction. This commitment to innovation not only addresses current industrial challenges but also aligns with the global shift towards sustainability and environmental responsibility.

In conclusion, Stauff Filters are an essential component of modern industrial systems, providing reliable filtration solutions that enhance equipment longevity, improve system performance, and reduce maintenance costs. Their adaptability across various industries and applications, coupled with ongoing technological innovations, makes them a critical investment for any organization looking to optimize their hydraulic systems. As the industry continues to evolve, Stauff Filters will undoubtedly remain at the forefront of filtration technology, contributing to safer, cleaner, and more efficient industrial processes.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!