Introduction to Pneumatic Fittings

Pneumatic fittings are vital components in systems that rely on compressed air to transmit power. They serve the essential function of connecting different parts of a pneumatic system, ensuring that air flows seamlessly between components. These fittings are designed to withstand high pressure and provide a leak-affordable connection, which is crucial for maintaining the efficiency and safety of pneumatic systems. Understanding the intricacies of pneumatic fittings can help engineers and technicians design more efficient systems and troubleshoot issues that may arise during operation.

The Importance of Pneumatic Fittings

In industrial settings, pneumatic fittings play a critical role in various applications. From assembly lines to packaging systems, these fittings ensure that the machinery operates smoothly and efficiently. The reliability of pneumatic systems largely depends on the quality of their fittings, as even minor leaks or failures can lead to significant operational disruptions. In fact, a small leak in a pneumatic system can result in a drop in overall efficiency, leading to increased energy consumption and higher operational costs. Therefore, selecting the right pneumatic fittings is essential for ensuring optimal performance and minimizing downtime in industrial processes.

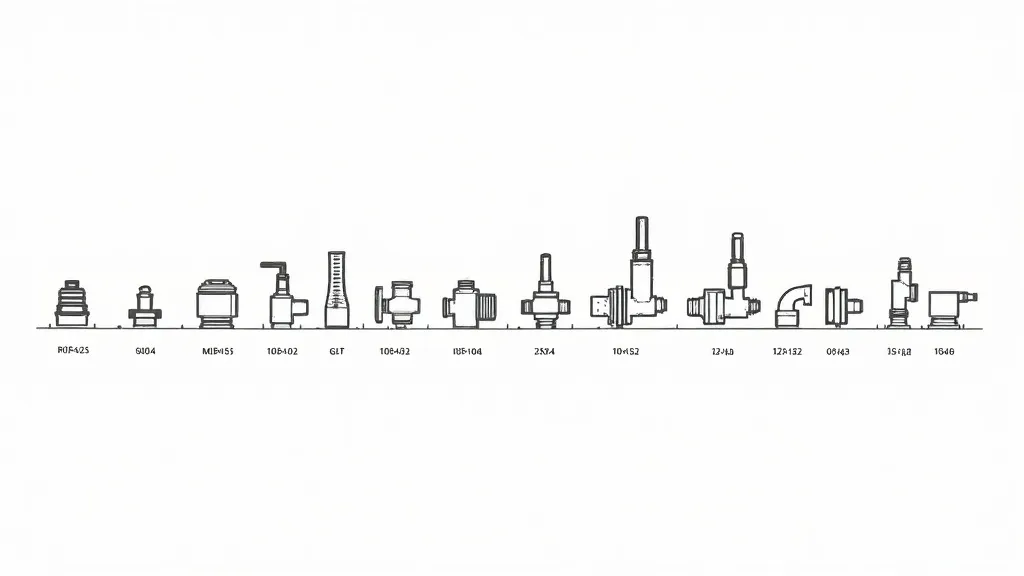

Types of Pneumatic Fittings

Pneumatic fittings come in various types, each serving a specific purpose. Some of the very common types include:

- Push-to-Connect Fittings: These are user-friendly fittings that allow for quick and easy connections without the need for additional tools. They are widely used in applications where frequent disconnection and reconnection are necessary, such as in automated machinery.

- Compression Fittings: Known for their strong and leak-proof connections, these fittings are ideal for high-pressure applications. They are commonly found in scenarios where high levels of pressure are a constant, such as in certain manufacturing processes.

- Threaded Fittings: These fittings use threads to secure connections, making them suitable for applications requiring high durability. They provide a robust connection that is less likely to loosen over time, which is particularly important in heavy-duty industrial settings.

- Quick-Disconnect Couplings: Designed for rapid connection and disconnection, these are perfect for systems requiring frequent maintenance or adjustments. They allow operators to quickly change tools or components without needing to shut down the entire system.

Material Considerations

The material of pneumatic fittings is a crucial factor that affects their performance and suitability for specific applications. Common materials include:

- Brass: Known for its durability and resistance to corrosion, making it suitable for various environments. Brass fittings are often used in applications that require a balance between strength and weight.

- Stainless Steel: Offers excellent corrosion resistance and strength, ideal for harsh or clean environments. Stainless steel fittings are particularly popular in the food and beverage industry, where hygiene is paramount.

- Plastic: Lightweight and resistant to corrosion, suitable for low-pressure applications. Plastic fittings are often used in industries where weight savings are essential, and they can help reduce overall manufacturing costs.

- Aluminum: Lightweight and resistant to corrosion, often used in applications where weight is a concern. Aluminum fittings are common in aerospace applications, where every gram counts.

Installation and Maintenance

Proper installation and maintenance of pneumatic fittings are essential to ensure the longevity and efficiency of pneumatic systems. Here are some key steps to follow:

- Selection: Choose the right type and size of fitting for your specific application. Consider factors such as the working pressure, flow rate, and the types of materials being conveyed.

- Inspection: Regularly inspect fittings for signs of wear or damage. Look for cracks, corrosion, or other indications that the fitting may no longer create a secure seal.

- Cleaning: Keep fittings clean to prevent contaminants from entering the system. Dust and debris can cause blockages and affect the performance of pneumatic systems.

- Replacement: Replace any worn or damaged fittings promptly to prevent system failure. Ignoring small issues can lead to larger, more costly problems down the road.

Pneumatic Fittings in Various Industries

Pneumatic fittings are used across a wide range of industries, each with unique requirements:

- Automotive: Used in assembly lines and manufacturing processes. Pneumatic systems help automate tasks such as painting, welding, and assembling components, improving efficiency and reducing labor costs.

- Aerospace: Essential for aircraft systems that rely on pneumatic power. Pneumatic systems are used for actuating landing gear, opening cargo doors, and other critical functions in flight.

- Food and Beverage: Used in machinery that requires clean and safe air supply. Pneumatic systems in this industry must adhere to strict hygiene standards to prevent contamination.

- Healthcare: Utilized in medical devices and equipment. Pneumatic systems are integral to devices such as ventilators, surgical tools, and diagnostic equipment, where precision and reliability are paramount.

- Construction: Used in tools like pneumatic nailers and impact wrenches. The construction industry relies on pneumatic tools for their efficiency and power, making pneumatic fittings essential for reliable operation.

- Textile: Used in machinery that processes fabrics and materials. Pneumatic systems help control the flow of materials and operate machinery like sewing machines and cutting tools.

Advancements in Pneumatic Fittings Technology

Over the years, technology has advanced significantly, leading to the development of more efficient and reliable pneumatic fittings. Innovations in materials, design, and manufacturing processes have improved the performance of these essential components. Some notable advancements include:

- Smart Fittings: With the integration of sensors and IoT technology, modern pneumatic fittings can now monitor pressure, flow rates, and leak detection in real-time. This data can be invaluable for predictive maintenance and optimizing system performance.

- Enhanced Sealing Technologies: Advances in sealing materials and designs have led to fittings that can maintain a secure seal under greater pressures and diverse environmental conditions, reducing the likelihood of leaks and failures.

- Modular Fittings: New modular designs allow for custom configurations, enabling users to easily adapt their systems without the need for extensive redesign. This flexibility is particularly beneficial in rapidly changing industrial environments.

Environmental Considerations

As industries strive to become more environmentally friendly, the role of pneumatic fittings in reducing energy consumption and waste is increasingly important. Efficient pneumatic systems can help minimize energy usage by:

- Reducing Air Leaks: Properly designed and maintained fittings can significantly decrease the amount of compressed air wasted due to leaks, which is a common issue in many facilities.

- Optimizing System Design: Advanced fittings allow for more efficient system layouts, which can reduce the energy required to move air through the system.

- Using Recyclable Materials: Many manufacturers are now producing fittings made from recyclable materials, contributing to a circular economy and reducing the environmental impact.

FAQs

- What are pneumatic fittings used for? Pneumatic fittings are used to connect parts of a pneumatic system to ensure efficient air flow. They are essential for the operation of various tools and machinery that rely on compressed air.

- How do I choose the right pneumatic fitting? Consider factors such as the application, pressure requirements, and material compatibility. It is also important to assess the environment in which the fitting will be used to ensure durability and reliability.

- Can pneumatic fittings be reused? While some fittings can be reused, it is generally recommended to replace them to ensure reliability. Reusing fittings can lead to issues if they are worn or damaged.

- What materials are pneumatic fittings made from? Common materials include brass, stainless steel, plastic, and aluminum. The choice of material largely depends on the specific application and environmental factors.

- What are the signs of a failing pneumatic fitting? Signs of a failing pneumatic fitting include visible wear, leaks, decreased pressure, or unusual noises during operation. Regular inspection is crucial in identifying these issues early.

- How can I prevent leaks in pneumatic fittings? To prevent leaks, ensure that fittings are properly installed, regularly inspected, and maintained. Using high-quality fittings and ensuring compatibility with the system can also help reduce the risk of leaks.

Conclusion

Pneumatic fittings are integral to the functionality and efficiency of pneumatic systems across various industries. Understanding the different types, materials, and applications of these fittings can help users make informed decisions that optimize performance and reliability. As technology continues to advance, the role of pneumatic fittings will evolve, leading to even greater efficiencies and capabilities in industrial processes. By prioritizing quality and maintenance, organizations can ensure that their pneumatic systems operate at peak performance, ultimately leading to improved productivity and reduced operational costs.

Future Trends in Pneumatic Fittings

Looking ahead, several trends are shaping the future of pneumatic fittings and pneumatic systems as a whole:

- Integration with Automation: As industries continue to embrace automation and robotics, pneumatic fittings will play an increasingly critical role in these systems. Enhanced compatibility with automated tools will streamline processes and improve overall efficiency.

- Focus on Energy Efficiency: With rising energy costs and a greater emphasis on sustainability, the demand for energy-efficient pneumatic systems will drive innovation in fitting design and materials. Manufacturers will focus on creating fittings that minimize energy loss.

- Customization and Flexibility: The ability to customize pneumatic systems to meet specific operational needs will become more important. This will lead to a growing demand for modular fittings and systems that can be easily adapted to changing requirements.

- Digitalization and Analytics: The integration of digital technologies into pneumatic systems will allow for better monitoring and control. Data analytics can provide insights that lead to improved performance and maintenance strategies.

Conclusion: The Role of Pneumatic Fittings in the Future

Pneumatic fittings are not merely connectors; they are essential components that contribute to the efficiency, reliability, and safety of pneumatic systems. As industries evolve and adapt to new technologies, the importance of high-quality pneumatic fittings will only increase. By staying informed about the latest advancements and best practices in pneumatic fittings, organizations can position themselves at the forefront of their respective industries, ensuring they remain competitive and capable of meeting the challenges of tomorrow.