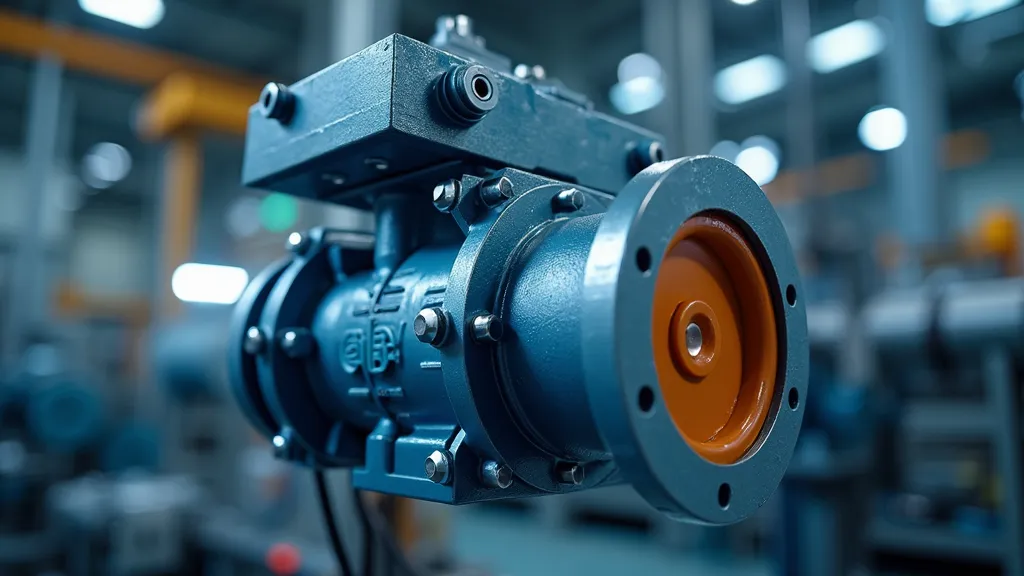

The Rexroth Servo Valve is a pivotal component in precision hydraulic systems, ensuring accurate control and efficiency. Renowned for its reliability and performance, it plays a critical role in various industrial applications. This article delves into the functionalities, benefits, and considerations when selecting a Rexroth Servo Valve for industrial use, providing expert insights for optimal application.

The Rexroth Servo Valve is an essential component in hydraulic systems, providing precise control over fluid flow and pressure. Known for its reliability and efficiency, it is widely used in various industrial sectors to enhance system performance and accuracy. This article explores the functionalities, advantages, and considerations when selecting a Rexroth Servo Valve, offering expert insights to optimize its application in industrial settings. The focus on technological advancements in the design of these valves contributes significantly to their popularity and effectiveness in demanding environments.

A servo valve is a device that modulates the flow of fluid to an actuator, controlling position, velocity, and force. The Rexroth Servo Valve, a leading product in this category, is designed for high precision and robust performance. It is a vital component in hydraulic systems, ensuring smooth operation and enhancing the efficiency of machinery. The operation of a Rexroth Servo Valve is based on the principle of feedback control, allowing real-time adjustments to fluid dynamics, thereby achieving desired performance levels in various applications.

Rexroth Servo Valves are utilized in numerous industries due to their versatility and precision. Common applications include:

When selecting a Rexroth Servo Valve, consider the following factors to ensure optimal performance:

| Factor | Consideration |

|---|---|

| Application Requirements | Determine the specific needs of your application, including pressure and flow rate. Understanding the operational parameters will guide you in selecting a valve that meets these criteria. |

| System Compatibility | Ensure the valve is compatible with existing machinery and control systems. This includes checking for electrical compatibility and the physical dimensions of the valve. |

| Environmental Conditions | Consider the operating environment, such as temperature and potential exposure to corrosive substances. Selecting a valve rated for the specific environmental conditions will enhance its longevity and performance. |

| Maintenance Needs | Evaluate the maintenance requirements and availability of technical support. Understanding the maintenance cycle and support options available can prevent unexpected downtime. |

| Response Time | Consider the response time required for your application. Some Rexroth Servo Valves offer faster response times, which may be critical for high-speed applications. |

| Control Type | Decide between analog and digital control valves based on your system's needs. Digital valves may offer advanced features such as diagnostics and remote monitoring capabilities. |

Rexroth Servo Valves are distinguished by their precision, reliability, and efficiency. They are engineered with advanced technology to meet the demanding needs of various industries. Their ability to integrate with sophisticated control systems and provide real-time feedback sets them apart from conventional valves.

Regular maintenance involves checking for leaks, ensuring proper lubrication, and inspecting for wear and tear. Following the manufacturer's maintenance guidelines is crucial for longevity. Additionally, utilizing condition monitoring tools can help in predicting maintenance needs before issues arise.

Yes, Rexroth Servo Valves are designed to perform in extreme conditions, including high temperatures and corrosive environments, thanks to their robust construction. Options for special coatings and materials can further enhance their resistance to environmental stressors.

Common issues may include erratic performance due to contamination, electrical faults in control signals, and mechanical wear over time. Proactive maintenance and regular inspections can help mitigate these issues before they escalate.

Improving the lifespan of a Rexroth Servo Valve can be achieved through proper installation, adherence to recommended maintenance schedules, and ensuring that the operating conditions remain within specified limits. Additionally, using high-quality fluids and filters can prevent contamination that can lead to premature wear.

The Rexroth Servo Valve is an invaluable component in modern hydraulic systems, offering superior control and efficiency. By understanding its features and applications, industries can make informed decisions to enhance their operational capabilities. Whether in aerospace or automation, the Rexroth Servo Valve stands out as a benchmark for quality and performance in hydraulic control solutions. As technology advances, the evolution of these valves will continue to meet the increasing demands of precision engineering, helping industries to innovate and improve productivity.

The field of servo valve technology is continuously evolving, driven by advancements in materials, electronics, and control algorithms. Future trends may include:

To illustrate the effectiveness of Rexroth Servo Valves in real-world applications, several case studies can be examined:

In a leading aerospace company, Rexroth Servo Valves were implemented in the flight control systems of a new jetliner. The goal was to improve the responsiveness and accuracy of the control surfaces, which are critical for flight safety. By utilizing advanced feedback control mechanisms, the valves enabled precise adjustments to the aircraft's ailerons and elevators, resulting in enhanced maneuverability and stability during flight. The implementation not only improved performance but also contributed to fuel efficiency, demonstrating how effective servo control can lead to multiple benefits.

In an automotive manufacturing plant, Rexroth Servo Valves were integrated into robotic arms used for assembling vehicle components. The need for high-speed operation coupled with precision was paramount to meet production targets. The servo valves provided the necessary control for the actuators, enabling the robotic arms to operate with high accuracy at increased speeds. This integration resulted in a significant reduction in cycle time and improved assembly accuracy, showcasing how servo technology can transform traditional manufacturing processes.

A plastics manufacturer faced challenges with cycle times and product consistency in their injection molding processes. By implementing Rexroth Servo Valves, they achieved better control over the injection pressure and speed. The valves allowed for precise adjustments during the molding process, leading to improved product quality and reduced scrap rates. The successful application of servo valves in this setting not only enhanced productivity but also positioned the manufacturer as a leader in quality within the industry.

Understanding the capabilities and potential applications of Rexroth Servo Valves is essential for engineers and decision-makers in various industries. As technology continues to advance, these valves will play an increasingly critical role in ensuring the efficiency and reliability of hydraulic systems. By staying informed about the latest developments and trends in servo valve technology, companies can harness the power of precision control to drive innovation and maintain a competitive edge in their respective markets.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!