This article explores the intricate world of Rexroth Servo Valves, essential components in industrial automation. Known for their precision and reliability, these valves are pivotal in controlling fluid flow, ensuring efficiency in various machinery. Readers will gain insights into their applications, benefits, and operational principles, enhancing their knowledge of industrial automation technologies.

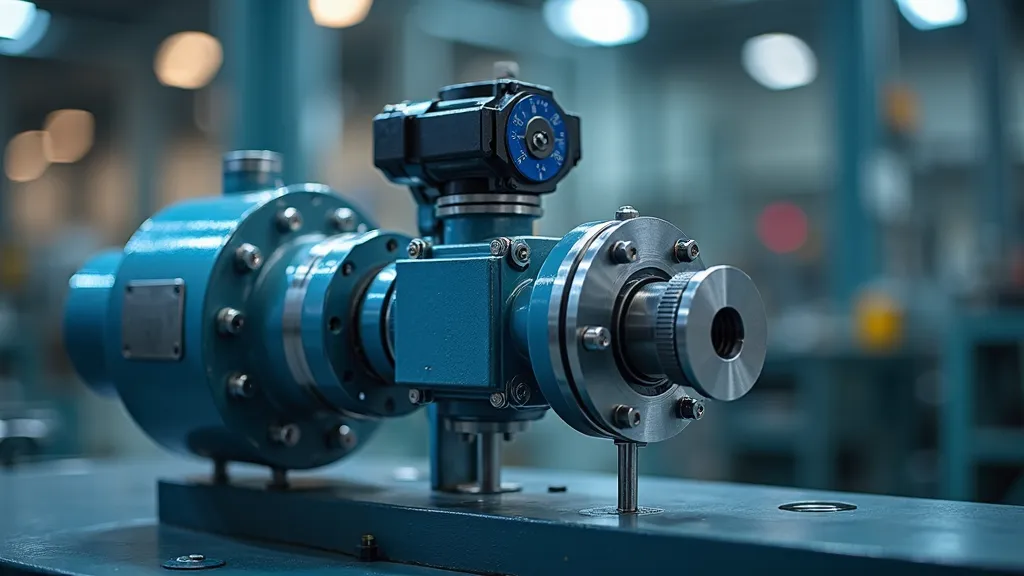

Rexroth Servo Valves are critical components in the realm of industrial automation, renowned for their precision and reliability. These valves play a pivotal role in controlling the flow of fluids, thereby ensuring the efficient operation of various machinery. In this article, we delve into the applications, benefits, and operational principles of Rexroth Servo Valves, offering an expert perspective on their significance in modern industry. The importance of these valves cannot be overstated, as they serve as the backbone of many automated systems, providing the necessary control to achieve desired outcomes in a range of processes.

Servo valves are essential in systems that require high levels of precision and control. They adjust the flow of hydraulic fluids with exceptional accuracy, which is crucial for applications ranging from aerospace to manufacturing. Rexroth, a leading name in this field, offers servo valves that are engineered to meet the stringent demands of today's industrial environments. The role of these valves extends beyond simple flow control; they are integral to the performance of complex automated systems, facilitating smooth and responsive motion in machinery. Their ability to maintain consistent performance under varying load conditions enhances the reliability of the overall system.

The applications of Rexroth Servo Valves are vast and varied. In the aerospace industry, they are used to manage flight control surfaces, ensuring precise movements necessary for safe and effective flight operations. For instance, they control the flaps and ailerons on aircraft, allowing for smooth maneuvers during flight. In manufacturing, these valves control the operation of machinery, enhancing efficiency and reducing downtime. They are frequently used in CNC machines and robotic arms, where precise movement and positioning are critical for production accuracy.

Other applications include robotics, where servo valves are integral to the movement of robotic limbs and tools, enabling complex tasks such as assembly and welding. In the automotive industry, they are utilized for various functions, including engine control systems and automated assembly lines, where precise fluid control can lead to better performance and energy efficiency. The power generation sector also benefits from Rexroth Servo Valves, as they help manage the hydraulic systems used in turbines and generators, ensuring optimal performance and reliability. The adaptable nature of these valves makes them suitable for a wide range of industries and applications, reinforcing their importance in modern technology.

The operation of a Rexroth Servo Valve involves the conversion of electrical input signals into precise hydraulic outputs. This process allows for the accurate positioning of mechanical components, which is essential in maintaining the desired performance of a system. The servo valve achieves this through a feedback loop, constantly adjusting to ensure the output matches the input signal. The feedback system typically involves sensors that monitor the output and relay this information back to the control system, allowing for real-time adjustments to maintain accuracy.

The valve's design typically features a spool that moves in response to the electrical signal, modulating the flow of hydraulic fluid. The position of the spool directly correlates with the input signal, which can come from a variety of sources, including controllers and sensors in the system. This interaction ensures that even the slightest changes in command are accurately translated into hydraulic movements, providing smooth and precise control. As systems become more advanced, the integration of digital control systems with Rexroth Servo Valves enhances their operational capabilities, enabling features such as remote monitoring and diagnostics, further improving efficiency and user experience.

Industry experts highlight the importance of regular maintenance and calibration of Rexroth Servo Valves to sustain their performance. Ensuring that these valves are operating within their specified parameters is crucial for the longevity of the systems they control. Maintenance practices may include regular inspection of hydraulic fluids for contamination, checking for leaks, and ensuring that the electrical connections and components are functioning correctly. Furthermore, advancements in technology continue to enhance the capabilities of these valves, offering even greater precision and efficiency. Innovations such as smart sensors and IoT connectivity are beginning to be integrated into Rexroth Servo Valves, allowing for predictive maintenance and improved operational insights.

Additionally, experts recommend that operators familiarize themselves with the specific requirements and operational characteristics of the Rexroth Servo Valves used in their systems. Understanding the manufacturer’s specifications and performance curves is essential for optimizing valve performance and ensuring that they are used effectively within their intended applications. Training programs and documentation provided by Rexroth can be invaluable resources for personnel involved in the operation and maintenance of these critical components.

In summary, Rexroth Servo Valves are indispensable in the world of industrial automation. Their ability to provide precise control over fluid dynamics makes them a critical component in various applications. The versatility of these valves allows them to be adapted for use in a wide range of systems, from aerospace to manufacturing, showcasing their importance across different industries. As technology advances, these valves continue to evolve, offering even greater capabilities and efficiencies. Understanding their operation and maintenance is essential for anyone involved in industries reliant on precise fluid control.

Moreover, the ongoing development in hydraulic technologies indicates that the future of Rexroth Servo Valves will likely include even more sophisticated features, such as advanced diagnostics, enhanced energy efficiency, and improved communication with other components in automated systems. This evolution will not only improve the performance of individual valves but also contribute to the overall efficiency and effectiveness of industrial processes. As businesses strive to maximize productivity and minimize costs, the role of reliable and precise components like Rexroth Servo Valves will become increasingly vital, solidifying their status as essential tools in the arsenal of modern industrial automation.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!