Stauff Filters play a crucial role in maintaining the efficiency of hydraulic systems by removing contaminants and ensuring fluid cleanliness. Originating from the German company Stauff, these filters are known for their reliability and innovation in various industrial applications. This guide provides a detailed look at their functions, benefits, and the importance of regular maintenance.

Stauff Filters are essential components in hydraulic and lubrication systems, designed to remove contaminants from fluids, thus maintaining system efficiency and longevity. These filters are produced by Stauff, a renowned German company known for its commitment to quality and innovation in the hydraulic sector. By ensuring fluid cleanliness, Stauff Filters help prevent system failures, reduce maintenance costs, and enhance overall performance.

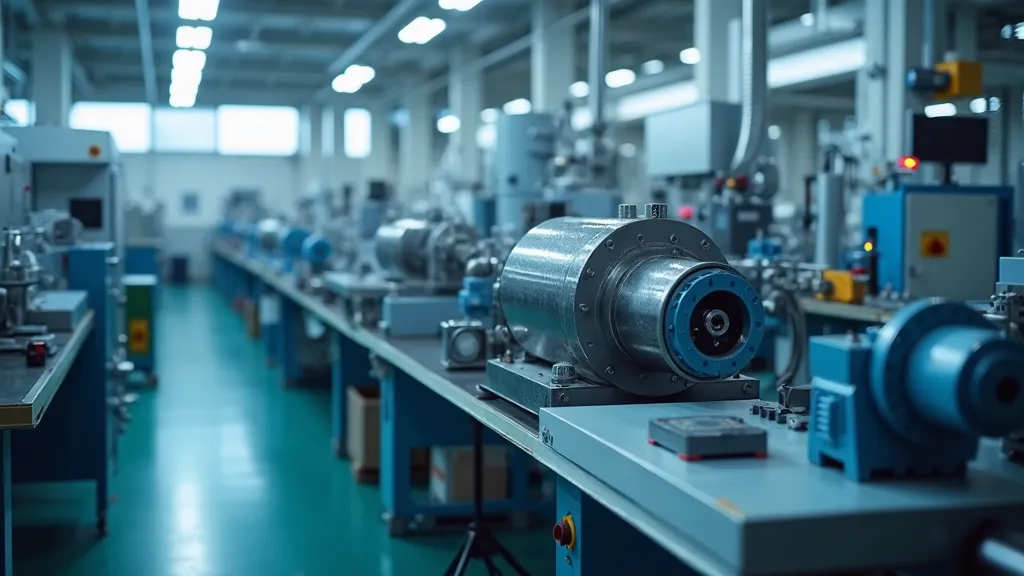

In a world where industrial machinery is the backbone of productivity, the role of fluid management cannot be understated. Hydraulic systems, which rely heavily on fluid power, are susceptible to a range of contaminants, including dirt, water, and metallic particles. These impurities can lead to severe performance issues, including decreased efficiency, increased wear and tear, and even catastrophic system failures. Therefore, understanding the importance of Stauff Filters is crucial for industries that depend on hydraulic systems.

Moreover, the increasing complexity of machinery and equipment makes it imperative to have reliable filtration solutions. With advancements in technology and the growing demand for higher operational efficiency, the need for effective filtration systems like Stauff Filters has become more pronounced. Their role extends beyond mere filtration; they contribute significantly to the overall operational health and safety of industrial processes.

Stauff Filters are engineered with precision and incorporate several features that make them stand out in the industry. They are recognized for their high dirt-holding capacity, superior filtration efficiency, and robust construction. These filters are versatile, suitable for a wide range of applications, including agriculture, construction, and manufacturing. Their benefits include extended equipment life, reduced downtime, and improved operational efficiency.

One of the most notable features of Stauff Filters is their ability to withstand high pressures and temperatures, making them suitable for rigorous industrial environments. The materials used in their construction are chosen for their durability and resistance to corrosion, ensuring that the filters can perform effectively over time, even in challenging conditions.

Additionally, Stauff Filters are designed with user-friendliness in mind. Many models include features such as visual contamination indicators that allow operators to easily monitor filter condition at a glance. This not only aids in timely maintenance but also helps in minimizing the risk of unexpected equipment failures. Furthermore, Stauff's commitment to innovation means that their filters are continually updated and improved based on the latest technological advancements and customer feedback.

The operational principle of Stauff Filters is based on trapping contaminants as fluid passes through the filter media. The design ensures that even the smallest particles are captured, thus maintaining clean fluid flow. Stauff offers a variety of filter elements, including suction filters, pressure filters, and return line filters, each tailored to specific system requirements and operational environments.

When fluid enters a Stauff Filter, it flows through a series of filter layers designed to capture different sizes of particles. The first layer captures larger contaminants, while subsequent layers target smaller particles. This multi-layered filtration process ensures that the fluid leaving the filter is as clean as possible. The efficiency of this filtration is measured in microns, with Stauff Filters capable of filtering particles down to a few microns in size.

In addition to their standard filtration capabilities, Stauff Filters can be equipped with advanced features such as water separation capabilities, which are particularly important in systems where moisture contamination is a concern. By removing water from the fluid, these filters help to prevent rust and corrosion in hydraulic systems, further extending the lifespan of components.

| Filter Type | Application | Features |

|---|---|---|

| Suction Filters | Used at the pump inlet to protect it from contaminants. | High flow rates, low pressure drop. |

| Pressure Filters | Installed downstream of the pump to protect sensitive components. | High dirt-holding capacity, durable construction. |

| Return Line Filters | Placed at the system return line to filter fluid before re-entering the reservoir. | Efficient contamination control, ease of maintenance. |

| Breather Filters | Used to filter air entering the hydraulic reservoir, preventing moisture and dust contamination. | Prevents moisture ingress, ensures clean air intake. |

| Offline Filters | Used in conjunction with hydraulic systems to provide additional filtration outside of the main flow circuit. | Enhanced filtration capacity, reduces system load. |

Regular maintenance of Stauff Filters is crucial to ensure optimal performance and longevity of hydraulic systems. This includes routine inspection, timely replacement of filter elements, and monitoring of fluid cleanliness. Implementing a maintenance schedule can prevent unexpected breakdowns and extend the life of system components.

Establishing a proactive maintenance culture is essential for industries that rely on hydraulic systems. This involves not only adhering to recommended maintenance schedules but also training personnel to recognize the signs of potential issues. Staff should be equipped with knowledge about the importance of filters and how to effectively monitor their condition.

In addition to routine checks, using advanced monitoring systems can significantly aid in filter maintenance. These systems can provide real-time data on fluid cleanliness, pressure differentials across filters, and potential contaminants in the system. By leveraging technology, facilities can reduce downtime and enhance overall operational efficiency.

Furthermore, it is important to consider the environmental aspects of filter maintenance. Proper disposal of used filter elements and contaminated fluids is crucial to minimize environmental impact. Many companies are now adopting eco-friendly practices, including recycling filter materials and using biodegradable hydraulic fluids, aligning their operations with sustainability goals.

In conclusion, Stauff Filters are vital for maintaining the health and efficiency of hydraulic systems. By understanding their functions and adhering to a regular maintenance routine, industries can ensure the longevity and reliability of their machinery. Investing in Stauff Filters is a step towards enhanced performance and reduced operational costs.

Furthermore, as industries evolve, the need for effective filtration solutions will continue to grow. Stauff's ongoing innovation and commitment to quality ensure that their filters will meet the ever-changing demands of the market. Whether it’s through introducing new filter technologies or enhancing existing products, Stauff remains at the forefront of the filtration industry.

In light of the increasing focus on sustainability and environmental responsibility, Stauff Filters also play a role in promoting greener practices within industries. By maintaining fluid cleanliness and improving system efficiency, these filters contribute to reduced waste and lower energy consumption. This alignment with sustainability goals not only benefits the environment but also enhances a company's reputation and competitiveness in the market.

Ultimately, the selection of the right filtration system is critical for any industrial operation. Stauff Filters not only provide superior performance and reliability but also offer peace of mind to operators and maintenance teams. With an array of options tailored to meet diverse needs, Stauff Filters stand as a testament to engineering excellence and innovation in the hydraulic sector.

In summary, the integration of Stauff Filters into hydraulic and lubrication systems is a strategic decision that can lead to significant long-term benefits. By ensuring fluid cleanliness, optimizing maintenance practices, and embracing technological advancements, industries can enhance their operational efficiency, reduce costs, and contribute positively to their sustainability objectives. Investing in quality filtration solutions like Stauff Filters is an investment in the future of industrial operations.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!