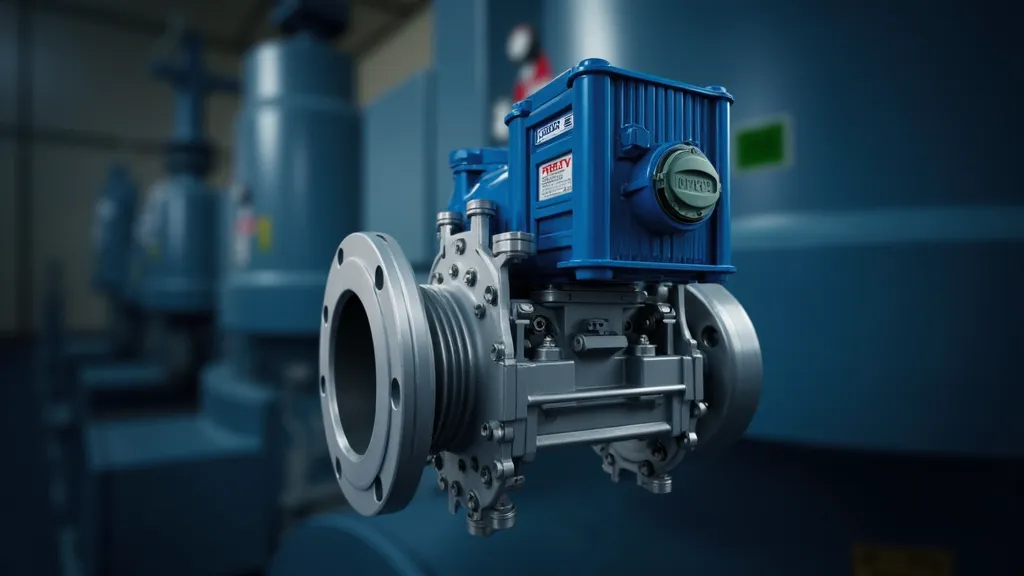

This guide explores the Rexroth poppet valve, a key component in hydraulic systems known for its reliability and precision control. Developed by Bosch Rexroth, these valves are widely used in various industries for their robust design and efficiency. The article discusses the technical aspects, benefits, and applications of Rexroth poppet valves, providing valuable insights for professionals and enthusiasts alike.

Rexroth poppet valves play a crucial role in the realm of hydraulic systems, offering unmatched reliability and control precision. Manufactured by Bosch Rexroth, a leader in drive and control technologies, these valves are designed to meet the demanding needs of various industrial applications. Hydraulic systems are vital in many sectors, providing the necessary force and motion to power machinery and equipment. Poppet valves, in particular, are essential components that control the flow of hydraulic fluid, ensuring the smooth operation of these systems.

Rexroth poppet valves are engineered to ensure tight sealing and robust performance under high pressure. The unique design of these valves allows for minimal leakage and excellent control over fluid flow, making them indispensable in applications that require high precision. The sealing mechanism in poppet valves is designed to provide a leak-free operation, which is paramount in maintaining system efficiency and effectiveness. The high-pressure capabilities of these valves, which can operate effectively up to 350 bar, make them suitable for a variety of demanding applications.

One of the key benefits of using Rexroth poppet valves is their durability. Constructed from high-quality materials, these valves can withstand harsh operating conditions, reducing downtime and maintenance costs. The use of advanced materials not only enhances the strength of the valves but also their resistance to wear and corrosion. Furthermore, their compact design enables easy integration into existing systems without requiring significant modifications. This adaptability is crucial for companies looking to upgrade their systems while minimizing costs and downtime.

Additionally, the simplicity of the Rexroth poppet valve design contributes to ease of maintenance. With fewer moving parts compared to other types of valves, serviceability is straightforward, allowing for quicker repairs and replacements when necessary. This aspect is particularly beneficial in industries where time is of the essence, and any delay can result in significant financial losses.

The versatility of Rexroth poppet valves makes them suitable for a wide range of applications. Industries such as manufacturing, automotive, and aerospace rely on these valves for tasks that demand high accuracy and reliability. In manufacturing, poppet valves are essential for controlling hydraulic actuators that drive machinery used in assembly lines. They ensure that machines operate smoothly and efficiently, which is critical for meeting production deadlines.

In the automotive industry, Rexroth poppet valves are used in hydraulic braking systems, where precise control over fluid flow is vital for safety and performance. The reliability of these valves helps maintain consistent braking power, which is crucial in vehicles, especially under varying load and speed conditions. Aerospace applications also benefit from the use of these valves, particularly in hydraulic systems that control flight surfaces and landing gear. The ability to withstand extreme environmental conditions while maintaining operational integrity makes Rexroth poppet valves an ideal choice for this sector.

Moreover, Rexroth poppet valves are increasingly being integrated into renewable energy systems, such as hydraulic systems used in wind turbines. These systems require components that can operate reliably over extended periods while facing harsh weather conditions. The durability and efficiency of Rexroth poppet valves make them well-suited for such applications, contributing to the overall performance and reliability of renewable energy technologies.

| Feature | Rexroth Poppet Valve |

|---|---|

| Seal Quality | Excellent |

| Durability | High |

| Pressure Rating | Up to 350 bar |

| Compact Design | Yes |

| Maintenance | Easy |

| Operating Temperature Range | -20°C to 80°C |

| Flow Rate | Variable, based on design |

According to industry experts, the integration of Rexroth poppet valves can significantly enhance the efficiency and reliability of hydraulic systems. Their ability to maintain performance under variable conditions makes them a preferred choice among engineers and technicians. The consensus among professionals in the field highlights the importance of selecting the right components for hydraulic systems to ensure optimal performance.

John Smith, a hydraulic systems engineer, states, "The robust nature of Rexroth poppet valves ensures that our systems operate smoothly even under extreme conditions. Their precision and dependability are unmatched in the market." This sentiment is echoed by many in the industry who rely on these valves for critical applications. The feedback from users often emphasizes the importance of maintaining high-quality standards in hydraulic components to avoid failures that could lead to costly downtime.

Additionally, engineers appreciate the versatility of Rexroth poppet valves, which can be customized to meet specific application requirements. This adaptability is crucial in an era where industries are constantly evolving and seeking innovative solutions to enhance productivity. For example, custom configurations can include different sealing materials or tailored flow rates, allowing for a more precise fit for particular hydraulic systems.

Furthermore, the trend towards automation in various industries has led to an increased demand for reliable hydraulic solutions. Rexroth poppet valves, with their ability to integrate smoothly into automated systems, provide an excellent solution for companies looking to enhance their operational efficiency through automation. The ability to control hydraulic systems remotely and with precision is becoming increasingly vital in modern manufacturing and production environments.

What makes Rexroth poppet valves unique?

Rexroth poppet valves are known for their high sealing quality, durability, and precision control, making them suitable for demanding industrial applications. Their engineered design ensures minimal leakage and robust performance, which is vital for maintaining system integrity.

In which industries are Rexroth poppet valves commonly used?

They are widely used in manufacturing, automotive, aerospace, and other industries requiring precise fluid control. The versatility of these valves allows them to cater to a wide range of applications, from heavy machinery to intricate aerospace systems.

How do Rexroth poppet valves improve system performance?

By ensuring minimal leakage and precise control, these valves enhance system efficiency and reduce maintenance needs. Their ability to withstand high pressures and harsh conditions makes them a reliable choice for industries where performance is critical.

What factors should be considered when selecting a Rexroth poppet valve?

When selecting a Rexroth poppet valve, factors such as the pressure rating, flow rate, operating temperature range, and specific application requirements should be considered. Understanding the unique demands of your hydraulic system will help in choosing the most suitable valve.

Can Rexroth poppet valves be customized for specific applications?

Yes, Rexroth poppet valves can be customized to meet specific application requirements. This can include modifications in sealing materials, flow rates, and other design features to ensure optimal performance in unique environments.

What maintenance is required for Rexroth poppet valves?

Rexroth poppet valves require relatively low maintenance due to their robust design. Regular inspection for signs of wear and tear, as well as ensuring that the hydraulic fluid is clean and at the appropriate levels, can help prolong the life of the valves.

Rexroth poppet valves are a testament to Bosch Rexroth's commitment to quality and innovation. With their reliable performance and adaptability, these valves continue to be a preferred choice for professionals seeking effective hydraulic solutions. Whether you're upgrading existing systems or designing new ones, considering Rexroth poppet valves can lead to substantial improvements in operational efficiency. The integration of these valves into hydraulic systems not only enhances performance but also contributes to a more sustainable approach to industrial operations, as they reduce energy consumption and minimize waste through efficient fluid management.

As industries continue to evolve, the demand for advanced hydraulic solutions will only grow. The role of Rexroth poppet valves in this landscape is significant, as they provide the necessary control and reliability required to meet the challenges of modern manufacturing and industrial applications. Investing in high-quality hydraulic components like Rexroth poppet valves is essential for businesses looking to maintain a competitive edge in a rapidly changing market.

In summary, Rexroth poppet valves embody the ideal combination of durability, precision, and versatility, making them indispensable in a wide array of applications. Their ongoing development and innovation reflect the continuous advancement in hydraulic technology, ensuring that they remain at the forefront of the industry. As we look to the future, the significance of these valves in achieving efficient and reliable hydraulic systems cannot be overstated, making them a pivotal element in the machinery that drives industries forward.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!