Rexroth Poppet Valves are critical components in hydraulic systems, known for their precision and reliability in controlling fluid flow. These valves, developed by Bosch Rexroth, are versatile solutions used across various industries, including manufacturing, automotive, and aerospace. Their robust design ensures long-lasting performance and efficiency in demanding environments.

In the realm of hydraulic systems, Rexroth Poppet Valves stand out for their efficiency and reliability. These valves are essential for controlling the flow of fluids within a system, ensuring that operations run smoothly and effectively. Manufactured by Bosch Rexroth, a leader in the field of drive and control technologies, these poppet valves are engineered to meet high standards of performance and durability. With a commitment to innovation, Bosch Rexroth continues to refine and enhance the technology behind their poppet valves, ensuring they stay at the forefront of hydraulic engineering.

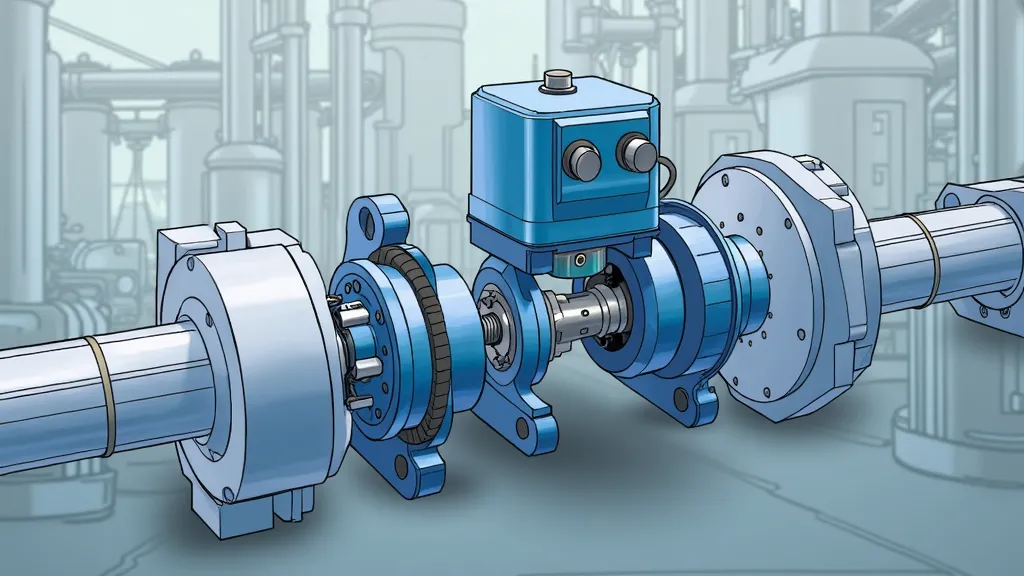

Poppet valves function by opening and closing passages through the motion of a movable element that seals against a valve seat. This design not only provides precise flow control but also ensures minimal leakage, which is crucial in maintaining the integrity of hydraulic systems. Rexroth Poppet Valves are particularly noted for their ability to handle high-pressure environments, making them suitable for a wide range of applications. The operation of these valves often involves hydraulic actuation, which allows for swift and responsive control over fluid dynamics, contributing to overall system efficiency.

Rexroth Poppet Valves offer numerous advantages, including:

These valves are employed across various sectors due to their adaptability and reliability. In manufacturing, they ensure the seamless operation of machinery by regulating hydraulic fluid flow. For instance, in automated assembly lines, Rexroth Poppet Valves are used to control the hydraulic cylinders that drive machinery, enabling precise and synchronized movements essential for efficient production.

In the automotive industry, they contribute to the efficiency of vehicle systems, such as power steering and braking systems, where reliability and precision are paramount. These valves help manage the hydraulic pressure that ensures adequate power assist in steering and consistent braking force, enhancing both safety and performance.

Moreover, their precision makes them indispensable in the aerospace sector, where accuracy is non-negotiable. In aircraft hydraulic systems, Rexroth Poppet Valves regulate the flow of hydraulic fluid that operates critical systems, such as landing gear and flaps, ensuring safety and reliability during flight operations.

Additionally, in the construction and mining industries, these valves play crucial roles in controlling heavy equipment, such as excavators and loaders. The ability to handle high-pressure applications efficiently makes Rexroth Poppet Valves ideal for environments where heavy loads and rigorous conditions are the norm. Their robustness ensures that operators can rely on their performance, even in the most challenging scenarios.

| Model | Pressure Range | Flow Capacity | Applications |

|---|---|---|---|

| Model A | Up to 350 bar | 100 L/min | General industrial use |

| Model B | Up to 500 bar | 200 L/min | Aerospace and automotive |

| Model C | Up to 700 bar | 300 L/min | Heavy machinery and mining |

Each of these models has been designed with specific applications in mind, ensuring that they meet the varying demands of different industries. When selecting a Rexroth Poppet Valve, it is essential to consider the operational requirements, including the pressure and flow demands of the specific application. By matching the right valve to the task, users can optimize performance and extend the lifespan of both the valves and the hydraulic systems they serve.

Q: What makes Rexroth Poppet Valves suitable for high-pressure applications?

A: Their robust design and high-quality materials enable them to withstand extreme pressures, ensuring reliable performance. The materials used in these valves are specifically chosen for their strength and resistance to fatigue, which is critical in high-pressure environments.

Q: Can Rexroth Poppet Valves be used in both mobile and stationary applications?

A: Yes, their versatile design allows them to be used in a wide range of settings, whether mobile or stationary. In mobile applications, such as construction equipment, these valves provide reliable control over hydraulic functions, while in stationary setups, they help manage fluid flow in fixed machinery.

Q: How do Rexroth Poppet Valves contribute to system efficiency?

A: By providing precise control over fluid flow, they help optimize system performance and reduce energy consumption. This precision not only enhances operational efficiency but also minimizes the risk of energy wastage, contributing to more sustainable practices in industrial operations.

Q: What maintenance practices are recommended for Rexroth Poppet Valves?

A: Regular inspection for signs of wear and tear is essential. It is advisable to check for leaks, ensure proper alignment, and verify that the valve is functioning as intended. Depending on the operating environment, more frequent maintenance may be necessary to ensure optimal performance.

Q: Are there specific installation guidelines for Rexroth Poppet Valves?

A: Yes, proper installation is crucial for the effective operation of these valves. It is important to follow the manufacturer’s specifications regarding orientation, torque settings, and connection types to prevent issues that could arise from improper installation.

Rexroth Poppet Valves are integral to the efficiency and reliability of hydraulic systems across industries. Their ability to perform under high-pressure conditions, combined with their versatility and precision, makes them indispensable in today’s technologically advanced applications. As industries continue to evolve, the role of these valves in ensuring seamless operations cannot be overstated. The ongoing advancements in hydraulic technology promise to enhance the capabilities of Rexroth Poppet Valves even further, paving the way for more innovative applications and improved system efficiencies.

As the demand for more efficient and reliable hydraulic systems grows, so too does the need for innovation in valve technology. Bosch Rexroth is at the forefront of this evolution, continuously researching and developing new features to enhance the performance of their poppet valves. Future innovations may focus on the integration of smart technology, allowing for real-time monitoring and control of hydraulic systems. This could involve sensors that provide feedback on valve performance, enabling predictive maintenance and further reducing downtime.

Moreover, advancements in materials science may lead to the development of even more robust and lightweight components, improving the overall efficiency of hydraulic systems. The use of advanced composites and alloys could enhance the durability of Rexroth Poppet Valves, making them suitable for even more extreme environments.

In addition to materials and technology improvements, the design of poppet valves is likely to evolve as well. Streamlined designs that reduce fluid resistance and enhance flow characteristics will be a key focus. This not only improves system performance but also contributes to energy savings, aligning with global sustainability goals.

As technology progresses, the integration of Rexroth Poppet Valves with smart hydraulic systems represents a significant leap forward. Smart hydraulic systems can leverage data analytics and machine learning to optimize performance, leading to enhanced productivity and reduced operational costs. By incorporating Rexroth Poppet Valves into these systems, operators can achieve unprecedented levels of efficiency and control.

The implementation of IoT (Internet of Things) technology within hydraulic systems allows for real-time data collection and analysis. This means that Rexroth Poppet Valves could be equipped with sensors that monitor parameters such as pressure, temperature, and flow rates. Data collected can be analyzed to predict maintenance needs, identify potential failures before they occur, and adjust operational parameters for optimal performance.

Such advancements not only reduce the likelihood of unexpected downtime but also enhance the overall reliability of hydraulic systems. By embracing these innovations, industries can significantly improve their operational efficiencies and reduce costs, while also ensuring that they remain competitive in an increasingly demanding market.

In conclusion, Rexroth Poppet Valves are not just a component of hydraulic systems; they are a critical part of the future of fluid control technology. Their ongoing development and integration with smart systems position them as essential tools for industries looking to enhance efficiency and reliability. As technology continues to evolve, the potential for Rexroth Poppet Valves to adapt and improve will ensure their relevance and importance for many years to come. The commitment of Bosch Rexroth to innovation and quality guarantees that these valves will remain at the cutting edge of hydraulic engineering, meeting the challenges of modern applications with precision and reliability.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!