This article delves into the intricacies of Rexroth Pressure Relief Valves, a crucial component in hydraulic systems that ensures safety by regulating excess pressure. These valves, known for their reliability and precision, are utilized across various industries to maintain optimal system pressure, thereby preventing potential damage or failure.

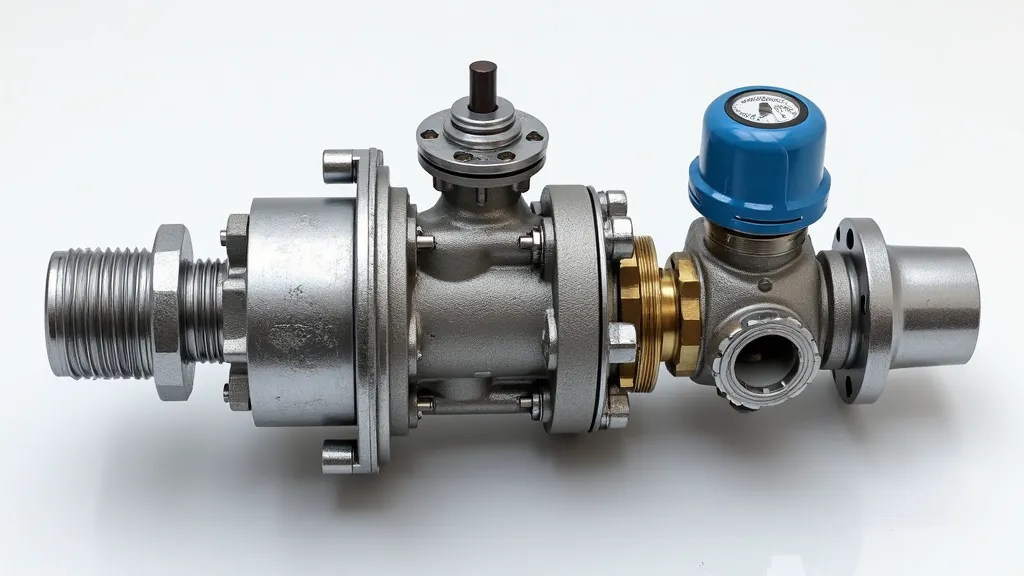

Rexroth Pressure Relief Valves are essential components in hydraulic systems, designed to manage and control pressure levels, ensuring the safety and efficiency of operations. These valves are engineered to prevent excessive pressure within hydraulic systems, which can lead to significant equipment damage or system failure. Trusted globally across numerous industries, Rexroth valves are synonymous with reliability and precision. Their innovative design and robust construction make them a preferred choice among engineers and technicians alike.

At the core of a pressure relief valve is its ability to maintain the desired pressure by diverting excess fluid when the pressure exceeds a pre-set limit. This mechanism not only protects the hydraulic system but also enhances its performance by maintaining consistent pressure levels. By doing so, it ensures that the system operates within its design specifications, thus prolonging the lifespan of the equipment. In essence, the pressure relief valve serves as a safety net, allowing hydraulic systems to function optimally while safeguarding against potential hazards.

The operational principle of a pressure relief valve is relatively straightforward. When the system pressure reaches the set limit, the valve opens, allowing hydraulic fluid to escape and thereby reducing the pressure. Once the pressure falls back below the set level, the valve closes, thus resuming normal operation. This automatic regulation of pressure helps in maintaining the balance within the hydraulic circuit, preventing conditions that could lead to catastrophic failures.

Rexroth valves are renowned for their robust construction and precision engineering. Key features include:

Rexroth Pressure Relief Valves are used in a multitude of industries, including manufacturing, construction, and agriculture. Their versatility allows them to be integrated into various systems, such as:

In addition to these common applications, Rexroth Pressure Relief Valves can also be found in specialized machinery used for aerospace, automotive, and energy production. Each application benefits from the unique features of Rexroth valves, ensuring that they meet the specific demands of high-performance hydraulic systems.

Choosing Rexroth Pressure Relief Valves offers numerous benefits, such as enhanced system efficiency, reduced downtime, and increased safety. Their precise control over pressure levels minimizes the risk of damage to other components, thereby lowering maintenance costs and extending the operational life of machinery. Additionally, incorporating these valves into hydraulic systems can lead to:

| Feature | Rexroth | Competitor A | Competitor B |

|---|---|---|---|

| Adjustability | High | Medium | Low |

| Durability | Very High | High | Medium |

| Reliability | Excellent | Good | Fair |

| Cost | Moderate | Low | High |

This table illustrates how Rexroth Pressure Relief Valves stand out in key performance areas compared to competitors. While some competitors may offer lower initial costs, the long-term benefits and reliability of Rexroth valves make them a more cost-effective solution for many businesses.

Q: What is the primary function of a Rexroth Pressure Relief Valve?

A: Its primary function is to regulate and control pressure within hydraulic systems to prevent excessive pressure build-up, thereby safeguarding the system components.

Q: Are these valves suitable for all types of hydraulic systems?

A: Rexroth valves are versatile and can be adapted for use in a wide range of hydraulic systems, but it is essential to select the appropriate model based on specific system requirements.

Q: How often should pressure relief valves be inspected or maintained?

A: Regular inspection and maintenance are recommended to ensure optimal performance. The frequency depends on the operational environment and the specific system in use. Typically, it is advisable to conduct inspections at least annually, or more frequently in harsh operating conditions.

Q: What materials are Rexroth Pressure Relief Valves made from?

A: Rexroth valves are typically made from high-grade steel or aluminum alloys, which provide the necessary strength and corrosion resistance required for hydraulic applications. The choice of materials contributes to their durability and long service life.

Q: Can Rexroth Pressure Relief Valves be used in mobile machinery?

A: Yes, Rexroth Pressure Relief Valves are designed to be compact and robust, making them suitable for mobile applications such as construction equipment, agricultural machinery, and transportation vehicles.

Proper installation of Rexroth Pressure Relief Valves is critical to ensure their effectiveness and longevity. Here are some general guidelines to follow:

To keep Rexroth Pressure Relief Valves functioning optimally, regular maintenance is essential. Here are some tips for effective maintenance:

As technology advances, so do the innovations in hydraulic components like pressure relief valves. Rexroth is continually working to improve their products through research and development. Future developments may include:

In conclusion, Rexroth Pressure Relief Valves are a critical component in ensuring the efficient and safe operation of hydraulic systems across various industries. Their reliability, durability, and precision make them an excellent choice for businesses seeking to enhance their system performance while minimizing risks and maintenance costs. By understanding the functionality, applications, and maintenance of these valves, operators can significantly improve the safety and efficiency of their hydraulic systems. As industries evolve and technology advances, Rexroth continues to lead the way in providing innovative solutions that meet the dynamic needs of modern hydraulics.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!