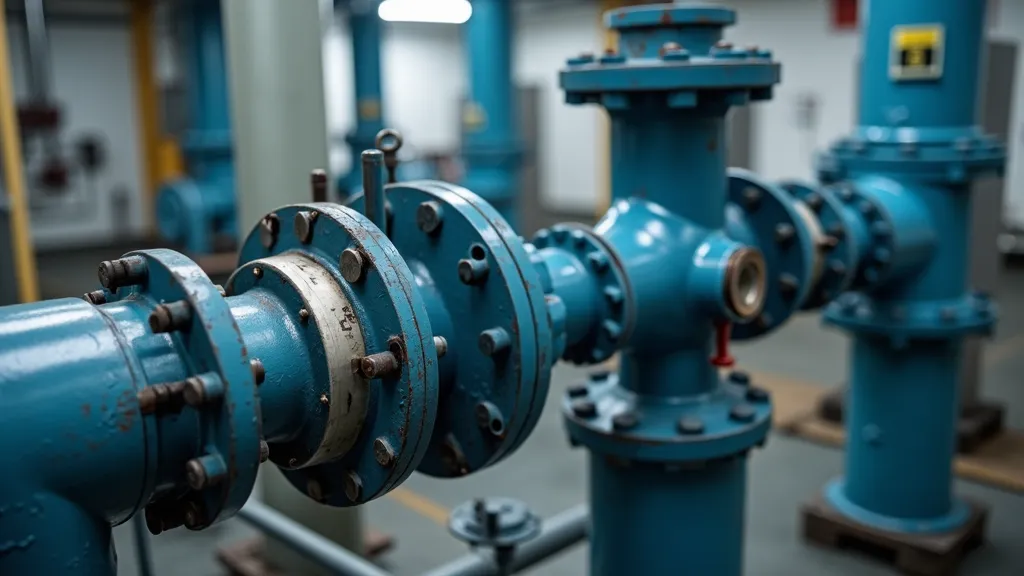

Rexroth Pressure Relief Valves are crucial components in hydraulic systems designed to regulate pressure and ensure safety. These valves are integral in preventing system failures by maintaining pressure within specified limits. Understanding their function, benefits, and application is essential for industries reliant on hydraulic machinery.

Rexroth Pressure Relief Valves are pivotal in maintaining the integrity and safety of hydraulic systems. These valves function by controlling and limiting the pressure within hydraulic circuits, preventing potential system failures and ensuring safe operation. As industrial processes become increasingly reliant on hydraulic technology, understanding the role and functionality of these valves becomes essential for engineers and technicians. In this comprehensive guide, we will delve deeper into the various aspects of Rexroth Pressure Relief Valves, including their construction, operating principles, and the importance of choosing the right model for different applications.

Pressure relief valves are a critical safety feature in hydraulic systems, protecting equipment from excessive pressure that could lead to malfunction or failure. The Rexroth brand is renowned for its reliability and efficiency in this domain, providing solutions that cater to various industrial needs. By automatically releasing pressure when it exceeds a set point, these valves maintain balance and prevent over-pressurization. The significance of pressure relief valves cannot be overstated; their failure can lead to catastrophic consequences, including equipment damage, safety hazards, and significant downtime in industrial processes.

Rexroth Pressure Relief Valves are utilized in numerous industries, including manufacturing, automotive, aerospace, and energy. In each of these sectors, the valves ensure that hydraulic systems operate within safe parameters, thereby enhancing efficiency and safety. For instance, in the automotive industry, these valves are critical in braking systems, ensuring driver and passenger safety by preventing brake failure. Similarly, in the aerospace sector, they play a vital role in hydraulic control systems, which are essential for the operation of aircraft control surfaces and landing gear.

In the manufacturing sector, pressure relief valves are commonly used in hydraulic presses and injection molding machines, where maintaining precise pressure levels is crucial for product quality and operational safety. In energy applications, such as hydraulic systems in wind turbines and oil rigs, these valves help manage the unique challenges posed by high-pressure environments, ensuring both safety and efficiency in energy production.

| Feature | Rexroth | Competitor A | Competitor B |

|---|---|---|---|

| Durability | High | Medium | High |

| Precision | High | High | Medium |

| Price Range | Premium | Economical | Mid-range |

| Maintenance | Easy | Moderate | Complex |

This comparison table highlights the strengths of Rexroth Pressure Relief Valves in terms of durability and precision. While they are positioned in the premium price range, the long-term benefits of investing in high-quality components often outweigh the initial costs. The ease of maintenance associated with Rexroth valves also contributes to lower operational costs over time, as less downtime translates to enhanced productivity.

When selecting a pressure relief valve, consider factors such as system pressure requirements, the type of fluid used, and environmental conditions. Rexroth offers a range of options that can be tailored to specific industrial needs. Consulting with a professional can ensure that the chosen valve aligns with both safety standards and operational goals. It is also crucial to assess the compatibility of the valve with the hydraulic circuit it will be integrated into, as this can significantly impact performance and safety.

Additionally, understanding the operational environment is essential. For example, if the valve will be used in an environment with high levels of contamination, selecting a model with enhanced sealing and filtration capabilities can help prolong the life of the valve and the overall hydraulic system. Similarly, if the application involves extreme temperatures, ensure the selected valve is rated appropriately for those conditions.

Rexroth Pressure Relief Valves are available with a variety of technical specifications that cater to specific application needs. Common specifications include:

These specifications highlight the versatility of Rexroth Pressure Relief Valves, making them suitable for a broad spectrum of industrial applications. When selecting a valve, it is essential to match these specifications with the requirements of the system to ensure optimal performance and safety.

Proper installation of Rexroth Pressure Relief Valves is crucial for ensuring their effective operation. Here are some general guidelines to follow during the installation process:

Following these installation guidelines will help maximize the performance and longevity of Rexroth Pressure Relief Valves, ensuring they function as intended within the hydraulic system.

Regular maintenance is critical to the longevity and functionality of Rexroth Pressure Relief Valves. Here are some best practices to consider:

By adhering to these maintenance practices, operators can ensure that Rexroth Pressure Relief Valves remain reliable and effective over their operational lifetime.

In conclusion, Rexroth Pressure Relief Valves are a critical component in ensuring the safety and efficiency of hydraulic systems across various industries. Their durability, precision, and ease of maintenance make them a preferred choice for many engineers and technicians seeking reliable pressure regulation solutions. Understanding their application and benefits can significantly enhance system performance and safety.

As industrial processes continue to evolve and embrace advanced hydraulic technologies, the importance of high-quality components like Rexroth Pressure Relief Valves becomes even more pronounced. Investing in these valves not only safeguards equipment but also contributes to the overall performance and reliability of hydraulic systems. By adhering to proper selection, installation, and maintenance practices, operators can ensure that their hydraulic systems remain efficient, safe, and ready to meet the demands of modern industrial applications.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!