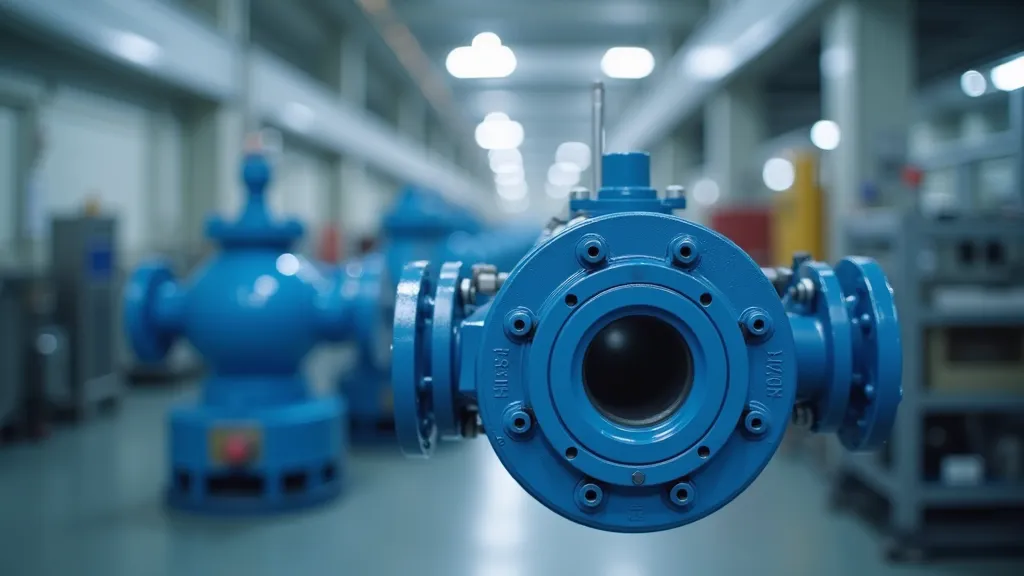

Rexroth Pressure Relief Valves are critical components in hydraulic systems, designed to protect machinery from overpressure conditions. These valves are integral to ensuring system safety and efficiency by maintaining optimal pressure levels. Known for their reliability and precision, Rexroth valves are widely used across various industries, including manufacturing, automotive, and aerospace.

Rexroth Pressure Relief Valves play a vital role in maintaining the safety and efficiency of hydraulic systems. These valves are engineered to prevent overpressure scenarios that could potentially damage machinery or cause system failures. By regulating and maintaining the desired pressure levels, Rexroth valves ensure smooth and uninterrupted operations across various industries. The design and functionality of these valves are the result of decades of engineering expertise and innovation, making them a cornerstone in hydraulic system management.

Pressure relief valves are essential for any hydraulic system as they act as a safeguard against excessive pressure buildup. Rexroth, a leader in industrial technology, offers a range of pressure relief valves known for their precision and reliability. These valves automatically release pressure when it exceeds a predefined limit, thereby protecting the system from potential damage. The functionality of pressure relief valves not only enhances system safety but also contributes to the overall efficiency of hydraulic operations by preventing unwanted pressure fluctuations that could lead to erratic system behavior. This is particularly important in complex hydraulic systems where fluctuations can lead to inconsistencies in performance.

Rexroth Pressure Relief Valves are utilized in numerous sectors, including manufacturing, automotive, and aerospace. In manufacturing, these valves help in maintaining the integrity of machinery by preventing pressure-related mishaps. For instance, in metal forming processes, maintaining precise pressure levels is crucial to avoid defects in the manufactured products. In the automotive industry, they ensure the safe and efficient functioning of hydraulic systems in vehicles, such as power steering and braking systems, where sudden pressure spikes could lead to catastrophic failures. In aerospace, where precision is paramount, Rexroth valves play a critical role in safeguarding complex hydraulic systems used in flight control and landing gear operations, where reliability is non-negotiable due to the potential risks involved.

Rexroth offers a diverse range of pressure relief valves, each designed to meet specific requirements. These valves vary in terms of pressure settings, flow rates, and sizes, allowing for customization based on the application. The robust construction and advanced materials used in these valves ensure durability and longevity, even under extreme conditions. For example, some Rexroth pressure relief valves are designed to withstand high temperatures and corrosive environments, making them suitable for use in chemical processing plants and oil rigs. Additionally, the valves are often equipped with features such as adjustable pressure settings and quick response times, enhancing their adaptability across various applications.

Rexroth’s model lineup includes several pressure relief valves that cater to different operational needs. Understanding the specific attributes of each model can assist engineers and technicians in selecting the appropriate valve for their application:

Proper installation and regular maintenance of Rexroth Pressure Relief Valves are crucial for optimal performance. It is advisable to follow manufacturer guidelines during installation to ensure correct placement and connection. Proper alignment and secure fittings are essential to prevent leaks and ensure accurate pressure regulation. Regular maintenance checks can help identify potential issues early, ensuring the longevity and efficiency of the valve. This includes inspecting for signs of wear or damage, checking the calibration settings, and ensuring that the valve is free of contaminants that could impede its functionality.

In addition to scheduled maintenance, operators should also be trained to recognize symptoms of valve malfunction, such as unusual noises, fluctuating pressures, or leaks. Being proactive in maintenance and monitoring can prevent costly downtime and repairs, thus enhancing the overall reliability of the hydraulic system.

Rexroth Pressure Relief Valves are indispensable for ensuring the safety and efficiency of hydraulic systems across different industries. With their robust design and precision engineering, these valves offer reliable protection against overpressure, safeguarding both machinery and operations. Whether in manufacturing, automotive, or aerospace, Rexroth valves stand out as a trusted choice for maintaining optimal system performance. As industries continue to evolve and demand higher standards of efficiency and safety, Rexroth's commitment to innovation ensures that their pressure relief valves will remain at the forefront of hydraulic technology.

To fully appreciate the functionality of Rexroth Pressure Relief Valves, it's essential to understand their internal mechanisms. The basic principle of a pressure relief valve is straightforward: it consists of a spring-loaded mechanism that holds a valve seat closed under normal pressure conditions. When the pressure within the hydraulic system exceeds the predetermined threshold, the force exerted by the fluid overcomes the spring tension, allowing the valve to open. This action releases excess pressure back to the reservoir or into a return line, preventing damage to the system.

There are several types of pressure relief valves, each serving distinct operations and needs. The most common types include:

Selecting the right pressure relief valve is critical for ensuring the safety and efficiency of hydraulic systems. Here are several factors to consider:

The field of hydraulic systems is continually evolving, leading to advancements in pressure relief valve technology. Future trends may include:

Real-world applications of Rexroth pressure relief valves highlight their effectiveness across various industries:

Rexroth Pressure Relief Valves are indispensable for ensuring the safety and efficiency of hydraulic systems across different industries. With their robust design and precision engineering, these valves offer reliable protection against overpressure, safeguarding both machinery and operations. Whether in manufacturing, automotive, or aerospace, Rexroth valves stand out as a trusted choice for maintaining optimal system performance. As industries continue to evolve and demand higher standards of efficiency and safety, Rexroth's commitment to innovation ensures that their pressure relief valves will remain at the forefront of hydraulic technology. The integration of advanced materials, smart technology, and automation into future designs will further enhance their capabilities, making them an essential component in the hydraulic systems of tomorrow.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!