This article explores the intricacies of Rexroth Poppet Valves, highlighting their essential roles in industrial applications. Known for their precision and reliability, these valves are employed to control the flow of fluids in various systems, ensuring operational efficiency and safety. The article delves into their functionality, benefits, and common questions to provide a thorough understanding for industry professionals and enthusiasts alike.

Rexroth Poppet Valves are pivotal components in hydraulic and pneumatic systems, renowned for their ability to control the flow of fluids with precision and reliability. These valves are integral to numerous industrial applications, providing critical control over fluid dynamics that can influence the efficiency and safety of entire systems. In this article, we will explore the functionalities, benefits, and common queries related to Rexroth Poppet Valves, offering insights from an industry expert's perspective. Additionally, we will delve into the various operational principles, maintenance practices, and advancements in valve technology that are shaping the future of fluid control systems.

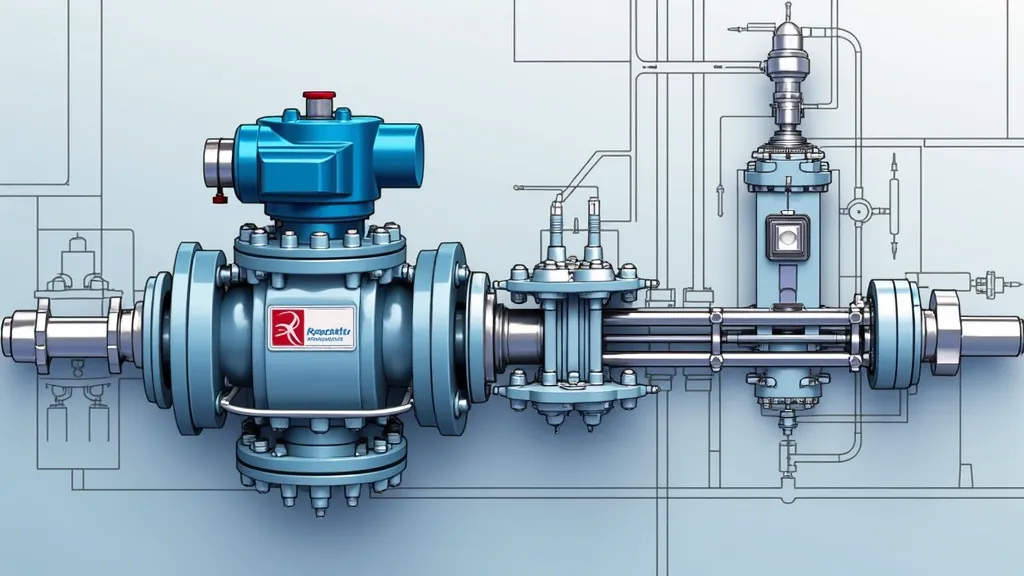

At the core of a Rexroth Poppet Valve is its unique design, which consists of a movable poppet that seals against a valve seat to control fluid flow. This mechanism allows for rapid opening and closing actions, making it ideal for applications requiring quick response times. The poppet valve's design minimizes leakage and wear, enhancing its longevity and reliability in demanding environments. Additionally, the valves are designed to withstand high pressures and temperatures, further solidifying their role in industrial settings.

The architecture of Rexroth Poppet Valves typically includes a robust housing made from high-grade materials such as stainless steel or specialized alloys that resist corrosion and wear. The poppet itself is often crafted from materials that ensure effective sealing and durability, such as reinforced plastics or composite materials. This combination of materials ensures that the valves can operate effectively under various environmental conditions, from high humidity levels to extreme temperatures.

Moreover, the integration of innovative sealing technologies, such as O-rings and advanced gasket designs, significantly enhances the reliability of these valves. These features are crucial in preventing leaks and ensuring that the valves can maintain their operational integrity over extended periods of service, even in the most challenging applications.

Rexroth Poppet Valves are employed in various industries, including automotive, aerospace, and manufacturing. In automotive systems, they are often used in braking systems to ensure precise control over hydraulic pressure. The ability to modulate pressure effectively contributes to the safety and responsiveness of braking systems, enhancing vehicle performance.

In aerospace, their reliability under extreme conditions makes them ideal for controlling hydraulic fluids in aircraft systems. The stringent regulatory requirements in this industry necessitate components that can operate flawlessly under a wide range of pressures and temperatures; thus, Rexroth Poppet Valves are favored for their robustness.

Manufacturing processes also benefit from the precision and durability of poppet valves, particularly in automated machinery where fluid control is paramount. For instance, in robotic assembly lines, the ability to regulate hydraulic pressure with precision can significantly impact the speed and efficiency of production.

Beyond these sectors, Rexroth Poppet Valves find applications in various other industries, including oil and gas, where they control the flow of drilling fluids; in renewable energy systems, such as those used in wind turbines; and in marine applications, where they manage hydraulic systems aboard vessels. Their adaptability to different operational needs underscores their importance across a spectrum of industrial applications.

Industry experts recognize Rexroth Poppet Valves for their exceptional performance and contribution to system efficiency. According to a report by the Hydraulic Institute, the global market for hydraulic valves is projected to grow significantly, driven by increasing automation and demand for efficient fluid control solutions. Rexroth, as a leading manufacturer, is poised to play a vital role in this growth with its innovative valve designs.

Recent technological advancements have enabled Rexroth to enhance the functionality of their poppet valves. For instance, the integration of smart technology and IoT capabilities allows for real-time monitoring and diagnostics. This innovation not only enhances the operational efficiency of systems but also aids in predictive maintenance, reducing downtime and operational costs. Furthermore, the application of machine learning algorithms can optimize valve performance over time, adapting to changing operational conditions and user requirements.

As industries continue to embrace automation and smart technologies, the demand for sophisticated fluid control solutions like Rexroth Poppet Valves is expected to surge. This trend is evident in sectors such as manufacturing, where Industry 4.0 initiatives are leading to increased investments in automation and advanced fluid control systems.

| Valve Type | Advantages | Disadvantages |

|---|---|---|

| Rexroth Poppet Valve | Precision control, durability, quick response, leakage resistance | Higher initial cost compared to some alternatives |

| Ball Valve | Simple design, easy to operate, good sealing capabilities | Poor throttling characteristics, can wear quickly under certain conditions |

| Gate Valve | Good for on/off control, minimal pressure drop, cost-effective | Not suitable for quick open/close operations, prone to wear |

| Globe Valve | Excellent throttling capability, good sealing performance | Higher pressure drop, slower response time |

| Check Valve | Prevents backflow, simple design | Limited control over flow rate, can cause pressure loss |

| Solenoid Valve | Fast operation, suitable for automation | Limited to low-pressure applications, potential for electromagnetic interference |

Rexroth Poppet Valves stand out in the realm of fluid control technology, offering unmatched precision, durability, and reliability. Their applications span multiple industries, underscoring their versatility and essential role in modern industrial systems. As technology advances and demands for efficient fluid control increase, Rexroth Poppet Valves are set to remain a cornerstone of industrial innovation.

Looking ahead, the evolution of Rexroth Poppet Valves will likely be influenced by the ongoing trends in automation and digitalization. Manufacturers are increasingly incorporating advanced technologies such as artificial intelligence and machine learning into their fluid control solutions, which will further enhance the operational capabilities of these valves. Moreover, as sustainability becomes a greater focus across industries, the development of energy-efficient valve systems and eco-friendly materials will play a crucial role in shaping the future of Rexroth Poppet Valves.

In conclusion, investing in Rexroth Poppet Valves not only ensures high performance and reliability but also positions industries to leverage the advancements in fluid control technology, paving the way for greater efficiency and innovation in the years to come.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!