Rexroth poppet valves are critical components in hydraulic systems, known for their reliability and efficiency in controlling fluid flow. These valves are widely used in various industrial applications due to their robust design and ability to withstand high pressures. This article explores the features, applications, and benefits of Rexroth poppet valves, offering insights into their role in modern hydraulic systems.

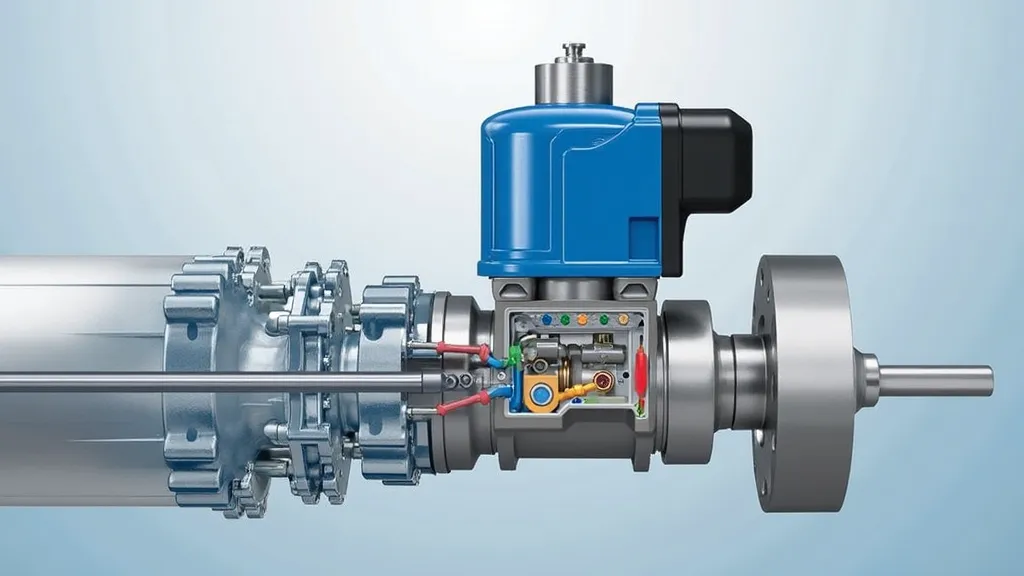

Rexroth poppet valves are pivotal in the realm of hydraulic systems, serving as crucial components that regulate fluid flow with precision and reliability. Engineered by Bosch Rexroth, a global leader in drive and control technologies, these valves are designed to meet the demanding needs of various industrial applications. Known for their robust construction and ability to function efficiently under high pressure, Rexroth poppet valves are integral to maintaining the performance and safety of hydraulic systems.

The versatility of Rexroth poppet valves extends beyond their primary function of flow regulation. They are capable of managing various fluid types, including oils and water-based solutions, making them suitable for multiple applications. Furthermore, their design allows them to function effectively in both open and closed-loop systems, which is essential in numerous hydraulic circuits. This adaptability solidifies their status as a preferred choice among engineers and system designers worldwide.

The primary feature of Rexroth poppet valves is their durability. These valves are constructed to endure the harsh conditions typical of industrial environments. They offer exceptional resistance to wear and tear, which is essential for operations that require continuous usage. The materials used in their construction, often high-grade steel or specialized alloys, not only provide strength but also enhance their corrosion resistance, ensuring longevity even in challenging conditions.

Another significant feature is their capability to handle high-pressure conditions. Rexroth poppet valves can manage pressures that other types of valves may not withstand, making them ideal for heavy-duty applications. The precision engineering of these valves allows for controlled fluid flow, which is crucial in applications requiring exact pressure and flow rate adjustments. This capability is particularly beneficial in systems where pressure fluctuations can lead to operational inefficiencies or even catastrophic failures.

Additionally, Rexroth poppet valves are designed with advanced sealing technologies that minimize leakage. This design not only enhances system integrity but also contributes to overall energy efficiency, as reduced leakage prevents loss of hydraulic fluid, thus maintaining optimal system performance. The valve's design also allows for easy integration into existing systems, facilitating upgrades or replacements without significant alterations to the hydraulic infrastructure.

The applications of Rexroth poppet valves are diverse, reflecting their versatility and reliability. These valves are commonly found in manufacturing plants, construction equipment, and automotive industries. In manufacturing, they are used to manage hydraulic presses and other machinery that require precise fluid control. For example, in metal forming processes, the precise control of hydraulic pressure is crucial for achieving the desired material properties and dimensional accuracy.

In construction, they are integral to the operation of excavators, cranes, and other heavy machinery, where stability and safety are paramount. The ability of these valves to withstand high-pressure environments makes them ideal for applications such as lifting heavy loads and controlling boom movements. Furthermore, in the automotive industry, Rexroth poppet valves play a crucial role in the operation of hydraulic systems used in vehicle assembly lines, ensuring reliable and efficient operation of machinery involved in manufacturing processes.

Additionally, Rexroth poppet valves are utilized in the agricultural sector, particularly in hydraulic systems for tractors and other farming equipment. Their ability to handle varying pressures and flow rates is essential for applications such as plowing, tilling, and harvesting, where precise control can significantly impact operational efficiency and crop yield. The versatility of these valves ensures they can adapt to the specific needs of different agricultural tasks, further cementing their importance in modern farming practices.

One of the primary benefits of Rexroth poppet valves is their contribution to increased efficiency in hydraulic systems. By ensuring precise control over fluid flow, these valves help optimize the performance of machinery, leading to reduced energy consumption and operational costs. This efficiency is critical in large-scale industrial operations, where even minor improvements in energy use can translate into significant cost savings over time.

Furthermore, the robustness of Rexroth poppet valves reduces the need for frequent maintenance, leading to lower operational expenses. In industries where downtime due to maintenance can result in substantial financial losses, the durability of these valves provides a significant advantage. Their design minimizes the risk of failures that could lead to costly repairs or replacements, ensuring that operations can continue smoothly.

Moreover, the reliability of Rexroth poppet valves enhances the safety of operations. In industrial environments where malfunctions can lead to significant downtime or hazards, the dependability of these valves is invaluable. Their design minimizes the risk of leaks and system failures, thereby protecting both the machinery and the operators. The incorporation of safety features, such as pressure relief mechanisms and fail-safe designs, further boosts their reliability, making them a prudent choice for critical applications.

| Feature | Rexroth Poppet Valve | Other Valves |

|---|---|---|

| Durability | High resistance to wear and tear | Varies, often less durable |

| Pressure Handling | Suitable for high-pressure applications | Limited to moderate pressures |

| Leakage Prevention | Minimal leakage design | Prone to leakage over time |

| Maintenance | Low maintenance requirements | Higher maintenance needs |

| Flow Control Precision | High precision in flow and pressure control | Less precise, often leading to fluctuations |

| Installation Flexibility | Easily integrates into existing systems | May require significant modifications |

| Operating Range | Wide range of operating conditions | Narrower operating range |

In conclusion, Rexroth poppet valves are indispensable components of modern hydraulic systems. Their durability, efficiency, and reliability make them ideal for a wide range of demanding applications. As industries continue to evolve, the role of these valves in enhancing operational efficiency and safety remains critical. With continuous advancements in technology, the future of Rexroth poppet valves looks promising, as they adapt to meet the changing needs of various sectors while maintaining their core attributes of performance and reliability.

The ongoing advancements in hydraulic valve technology are shaping the future of Rexroth poppet valves and similar components. One notable trend is the increasing integration of smart technology in hydraulic systems. As industries embrace the Internet of Things (IoT), hydraulic valves, including poppet valves, are being equipped with sensors and connectivity features that enable real-time monitoring and control. This shift allows for predictive maintenance, reducing downtime and enhancing operational efficiency.

Additionally, the push for energy efficiency and sustainability is leading to the development of more eco-friendly hydraulic solutions. Manufacturers are focusing on reducing energy consumption and minimizing the environmental impact of hydraulic systems. Rexroth poppet valves are expected to evolve in design and materials to meet these sustainability goals, potentially incorporating biodegradable fluids and recyclable materials in their construction.

Moreover, the demand for compact and lightweight hydraulic solutions is driving innovation in valve design. As machinery becomes more mobile and space-efficient, the need for smaller yet high-performance valves is paramount. Rexroth is investing in research and development to create poppet valves that maintain their reliability while being more compact, providing manufacturers with the flexibility they need in modern production environments.

To illustrate the effectiveness of Rexroth poppet valves, several case studies highlight their application in real-world scenarios:

In a leading automotive assembly plant, the integration of Rexroth poppet valves into the hydraulic systems of robotic arms significantly improved operational efficiency. The precision control offered by the valves allowed for accurate movements, reducing the cycle time for assembling vehicles. Consequently, the plant reported a 15% increase in productivity, along with a notable decrease in hydraulic fluid consumption due to reduced leakage and optimized flow rates.

A major construction company utilized Rexroth poppet valves in their fleet of hydraulic excavators. The valves' ability to handle high pressures ensured that the machinery could perform heavy digging tasks without risking hydraulic failure. The company noted a drastic reduction in maintenance costs and downtime, with a 20% improvement in the lifespan of their hydraulic systems. This success led to the company standardizing Rexroth poppet valves across all their equipment.

In an agricultural setting, a farmer implemented Rexroth poppet valves in his tractor's hydraulic system to control various attachments, such as plows and seeders. The valves provided precise control over the hydraulic flow, enhancing the efficiency of farming operations. As a result, the farmer was able to increase his yield and reduce fuel consumption, emphasizing the cost-effectiveness of using high-quality hydraulic components in agriculture.

Rexroth poppet valves stand out in the hydraulic systems landscape due to their robustness, precision, and adaptability. The case studies presented illustrate their capacity to enhance performance across various industries, from automotive manufacturing to agriculture. As technology progresses and industries evolve, Rexroth poppet valves will undoubtedly continue to play a critical role in driving efficiency, safety, and sustainability in hydraulic systems worldwide. Their ongoing development promises to meet the future demands of hydraulic applications, ensuring they remain at the forefront of industrial innovation.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!