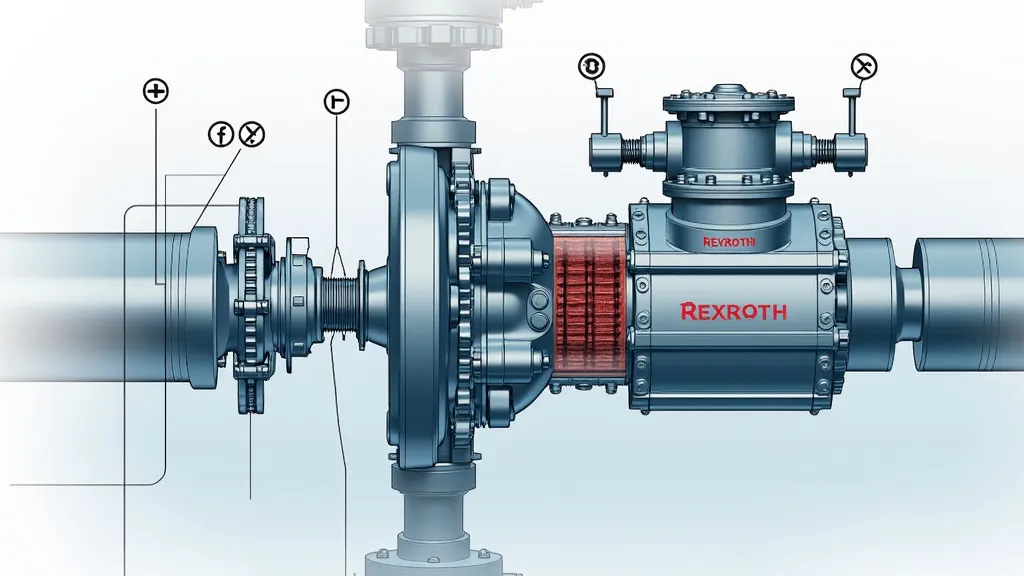

This article delves into the intricate details of the Rexroth Poppet Valve, a crucial component in fluid control systems. Known for its durability and precision, the poppet valve plays a significant role in regulating flow and pressure in various industrial applications. The content provides an expert analysis of its functions, applications, and operational benefits, making it an essential read for professionals in the field.

Rexroth poppet valves are integral components in fluid control systems, known for their precision and reliability. These valves are designed to regulate the flow and pressure of fluids in a variety of industrial applications, ensuring efficiency and safety in operations. As a leading name in the industry, Rexroth has consistently produced high-quality valves that meet the rigorous demands of modern engineering. With decades of experience and innovation, Rexroth has established a reputation for delivering products that not only meet but exceed customer expectations. The versatility of Rexroth poppet valves makes them suitable for various applications, from simple to complex systems, allowing industries to streamline operations and enhance productivity.

Poppet valves operate by opening and closing ports to control fluid flow. The valve's design allows for quick response times and robust sealing capabilities, making it ideal for applications where precise control is necessary. The poppet's movement is typically controlled by an actuator, which adjusts the valve's position based on system requirements. This mechanism ensures that the valve can handle high pressures and flow rates without compromising performance. The construction of poppet valves usually involves a disc or cone-shaped component that seals against a seat, preventing backflow and ensuring that the flow direction is maintained. This design allows for minimal leakage and loss of pressure, which is crucial in systems requiring high efficiency.

Rexroth poppet valves are widely used in industries such as automotive, aerospace, and manufacturing. In the automotive sector, these valves are crucial in the operation of hydraulic systems, including brakes and transmissions. In aerospace, they ensure the precise control of fluid systems necessary for aircraft operation. Manufacturing plants rely on poppet valves for automated processes that require exact fluid control to maintain product quality and consistency. Moreover, Rexroth poppet valves are also utilized in marine applications, where they help manage hydraulic systems for steering and propulsion. The versatility of these valves extends to construction equipment, where they facilitate the operation of hydraulic cranes and excavators, ensuring safety and efficiency on job sites.

The primary benefits of using Rexroth poppet valves include their durability, precision, and reliability. Made from high-quality materials, these valves can withstand harsh conditions and good use without significant wear. Their precision in controlling flow and pressure ensures that systems operate efficiently, reducing the risk of malfunctions and downtime. Additionally, the reliability of Rexroth valves means less frequent maintenance and replacement, saving time and costs for industries. Enhanced safety features are also a significant advantage, as Rexroth poppet valves are designed to prevent catastrophic failures, which can lead to costly repairs and safety hazards. Furthermore, the customization options available allow businesses to tailor these valves to their specific operational needs, maximizing functionality and effectiveness.

| Feature | Description |

|---|---|

| Material | High-grade steel and alloys for durability and strength, ensuring longevity in demanding environments. |

| Pressure Rating | Can handle high-pressure systems up to specified limits, catering to various industrial requirements. |

| Flow Rate | Optimized for efficient fluid control across various applications, maximizing throughput and minimizing energy consumption. |

| Actuation | Available in manual, hydraulic, and electric actuation options, providing flexibility in operation and control. |

| Sealing Mechanism | Advanced sealing technologies reduce leakage and ensure optimal performance over time. |

| Temperature Range | Designed to operate effectively in extreme temperature conditions, making them suitable for a wide range of applications. |

Proper installation and maintenance of Rexroth poppet valves are crucial for optimal performance. Installation should be performed by trained professionals who understand the specific requirements of the system. Regular maintenance includes checking for leaks, ensuring the actuator functions correctly, and replacing worn components as needed. Adhering to manufacturer guidelines will prolong the valve's lifespan and maintain system integrity. It is also recommended to conduct periodic inspections to assess the overall condition of the valves, including checking for signs of corrosion or wear. Utilizing diagnostic tools can help identify potential issues before they escalate, allowing for proactive maintenance strategies and minimizing unplanned downtime.

Rexroth valves are renowned for their high-quality construction, precision, and durability, making them a preferred choice for industries worldwide. Their reputation is built on extensive research and development, ensuring that each valve meets the highest performance standards.

Yes, Rexroth poppet valves are designed to withstand extreme temperatures and pressures, making them suitable for a wide range of environments. Their robust construction ensures reliable operation even under challenging conditions, such as high humidity, exposure to chemicals, or extreme temperatures.

Regular maintenance should be conducted based on usage frequency and environmental conditions, typically every six months to a year. However, in high-demand applications, more frequent checks may be necessary to ensure optimal performance. Implementing a preventive maintenance schedule can help extend the life of the valves and improve overall system reliability.

Rexroth poppet valves are utilized across various industries, including automotive, aerospace, manufacturing, marine, and construction. Each sector benefits from the valves' reliability and precision, which contribute to enhanced operational efficiency and safety.

Yes, Rexroth offers customization options to meet specific customer requirements. This includes variations in size, pressure ratings, and actuation methods, allowing businesses to tailor the valves to their unique applications.

The Rexroth poppet valve is a testament to engineering excellence, offering unmatched control and reliability in fluid systems. Its application across various industries highlights its versatility and importance in maintaining operational efficiency. For businesses seeking quality and performance, Rexroth poppet valves are an investment that promises good benefits and satisfaction. As industries continue to evolve, the demand for advanced fluid control solutions will grow, making Rexroth poppet valves a critical component in the future of engineering and manufacturing. By choosing Rexroth, companies can ensure that they are using some of the best technology available, which will ultimately translate to improved productivity and success in their operations.

As technology continues to advance, the future of Rexroth poppet valves is poised for exciting developments. Innovations in materials science are leading to the creation of even more durable and lightweight materials, enhancing the performance characteristics of poppet valves. Additionally, the integration of smart technology and IoT capabilities is becoming increasingly prevalent. This includes sensors that can provide real-time data on valve performance, enabling predictive maintenance and reducing the risk of failures.

Moreover, the growing emphasis on sustainability is pushing manufacturers to develop more environmentally friendly hydraulic solutions. Rexroth is actively exploring ways to reduce energy consumption in hydraulic systems, leading to more efficient valve designs that minimize energy loss. This not only benefits the environment but also contributes to cost savings for businesses.

Another trend is the adaptation of poppet valves for use in renewable energy applications. As the world shifts towards greener energy sources, poppet valves can play a critical role in managing hydraulic systems in wind turbines and solar energy installations. Their reliability and precision make them suitable for controlling fluid power systems that are essential for the operation of these technologies.

To illustrate the effectiveness and versatility of Rexroth poppet valves, let’s examine a few case studies from various industries that have successfully implemented these valves in their operations.

A leading automotive manufacturer faced challenges with the hydraulic braking system in their new line of electric vehicles. The previous system was prone to leaks and inefficiencies, leading to performance issues and increased maintenance costs. By integrating Rexroth poppet valves into their hydraulic system, the manufacturer was able to achieve precise control over fluid flow and pressure. The result was a significant reduction in leaks and an overall enhancement in braking performance. This improvement not only increased safety but also reduced the need for frequent maintenance, leading to lower operational costs.

An aerospace company needed to upgrade its hydraulic systems for a new aircraft model. The requirements included lightweight components that could withstand extreme pressure and temperature variations. Utilizing Rexroth poppet valves, the company successfully designed a hydraulic system that met all safety and performance standards while keeping the weight to a minimum. The valves provided precise control necessary for the sensitive operations of the aircraft, contributing to its overall performance and efficiency.

In a large-scale manufacturing facility, the need for automation led to the integration of hydraulic systems for assembly lines. The challenge was to ensure that the fluid control systems operated seamlessly to enhance production rates. By deploying Rexroth poppet valves, the facility was able to streamline its processes, achieving faster cycle times and improved product consistency. The precise control offered by the valves allowed for more efficient use of resources and reduced waste, positively impacting the bottom line.

As industries expand into emerging markets, the demand for reliable and efficient fluid control systems is increasing. Rexroth poppet valves are well-positioned to meet this demand due to their adaptability and proven performance. Emerging markets are often characterized by rapidly growing industrial sectors, including automotive, manufacturing, and energy. With the rise of these industries, the need for advanced hydraulic systems becomes paramount.

Rexroth's commitment to quality and innovation enables it to support businesses in these markets effectively. By providing training and support to local manufacturers and engineers, Rexroth helps ensure that the implementation of poppet valves leads to enhanced operational efficiencies. Furthermore, the introduction of cost-effective solutions tailored to the specific needs of emerging markets can facilitate the adoption of advanced hydraulic technologies, driving growth and development in these regions.

In conclusion, Rexroth poppet valves are not just components in fluid control systems; they are essential tools that empower industries to operate efficiently, safely, and sustainably. With their proven track record and continuous innovation, these valves will continue to play a crucial role in the future of engineering. As businesses face new challenges and opportunities, the reliability and performance of Rexroth poppet valves will be indispensable in achieving operational excellence. By investing in these advanced technologies, companies can position themselves for success in an increasingly competitive and dynamic market.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!