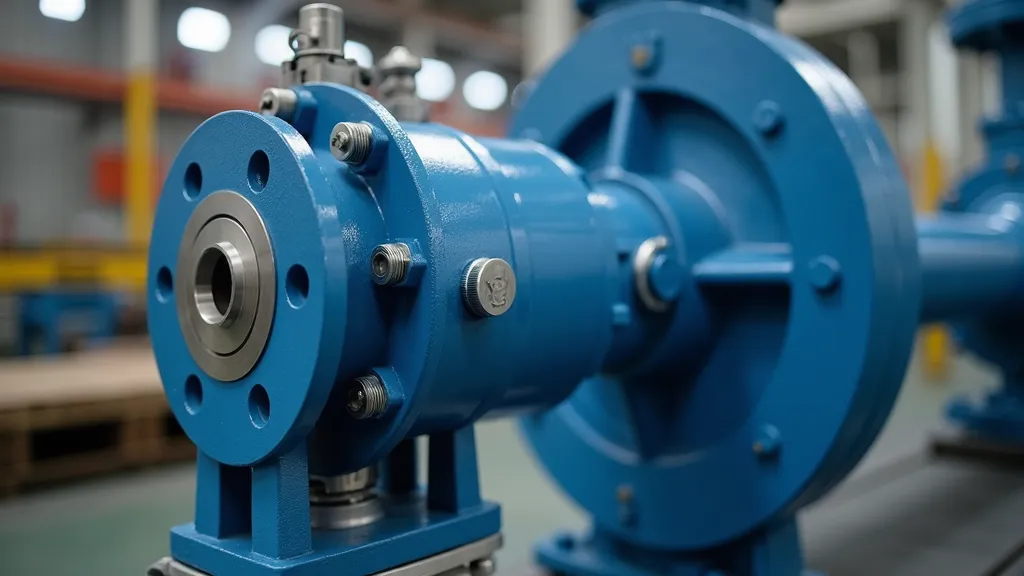

Rexroth Pressure Relief Valves are essential components in hydraulic systems, designed to protect equipment from excessive pressure by diverting fluid flow. These valves ensure system safety and efficiency. This article delves into the intricacies of Rexroth Pressure Relief Valves, exploring their functionality, benefits, and industry applications, alongside expert insights into their maintenance and selection criteria.

In the realm of hydraulic systems, maintaining optimal pressure levels is critical for both safety and operational efficiency. Rexroth Pressure Relief Valves play a pivotal role in this regard, serving as a safeguard against pressure overloads that can damage equipment and halt operations. By automatically diverting excess hydraulic fluid, these valves ensure the system operates within its designed parameters.

Hydraulic systems are integral to numerous industrial applications, where they serve as the backbone for machinery operation, material handling, and the automation of processes. The role of pressure relief valves extends beyond mere pressure management; they are essential for preventing catastrophic failures that could result in equipment damage, production downtime, and even personal injury. As such, understanding the intricacies of these valves can empower operators and engineers to make informed decisions about their hydraulic systems.

Pressure relief valves, such as those manufactured by Rexroth, are designed to open at a predetermined pressure level. This mechanism allows them to prevent potential system failures by releasing excess pressure. The function is straightforward but crucial: when the system pressure exceeds a set point, the valve opens, allowing fluid to flow out of the system until the pressure returns to safe levels. This functionality is vital in a variety of scenarios, such as during sudden fluctuations in demand or when components within the system degrade over time, leading to an increased risk of pressure buildup.

Moreover, the importance of these valves transcends their basic operation. They contribute to the overall safety architecture of hydraulic systems, acting as a fail-safe that can avert disasters. For instance, in industrial settings where heavy machinery operates, an unexpected pressure spike might lead to equipment failure or even injuries to personnel. The presence of a reliable pressure relief valve mitigates these risks, ensuring that operations can continue smoothly and safely.

Rexroth Pressure Relief Valves find applications across a wide range of industries, including manufacturing, automotive, aerospace, and agriculture. In each of these sectors, the valves are crucial for protecting machinery and ensuring the uninterrupted flow of operations. For instance, in manufacturing, these valves help maintain the precision and safety of automated systems. They are often employed in hydraulic presses, injection molding machines, and other automated equipment where precise pressure control is essential.

In the automotive industry, Rexroth Pressure Relief Valves are utilized within hydraulic braking systems to prevent over-pressurization, thus ensuring reliable braking performance. Similarly, in the aerospace sector, where safety is paramount, these valves are integral to hydraulic systems that operate landing gear, flight controls, and other critical components. The agricultural sector also benefits from these valves, particularly in hydraulic-driven equipment such as tractors and harvesters, where they ensure the reliability and safety of operations in the field.

The versatility of Rexroth Pressure Relief Valves allows them to be tailored for specific applications, with various configurations and specifications available to meet the unique demands of different industries. This adaptability ensures that regardless of the operational context, these valves can provide the necessary pressure control to safeguard system integrity.

Choosing the right pressure relief valve involves several considerations:

| Criteria | Considerations |

|---|---|

| Pressure Rating | Ensure the valve can handle the maximum pressure of your system. This is critical to avoid valve failure and potential system breakdown. |

| Material Compatibility | The valve material must be compatible with the hydraulic fluid used. Chemical reactions between the fluid and valve materials can lead to premature failure. |

| Flow Capacity | Determine the amount of fluid the valve can handle to prevent system overload. An undersized valve may not relieve pressure efficiently, leading to dangerous conditions. |

| Installation Environment | Consider the environmental conditions, such as temperature and exposure to elements, where the valve will be installed. Harsh environments may require valves with enhanced protective features. |

| Response Time | The speed at which a valve responds to pressure changes can be crucial in applications where rapid fluctuations occur. Ensure the selected valve meets the necessary response time requirements. |

| Compliance and Standards | Check if the valve meets relevant industry standards or certifications, which can be crucial for regulatory compliance and safety assurance. |

These selection criteria highlight the importance of thorough consideration when integrating pressure relief valves into hydraulic systems. Each factor plays a significant role in ensuring that the selected valve will perform effectively and reliably under the specific conditions of use.

To ensure the longevity and efficiency of Rexroth Pressure Relief Valves, regular maintenance is essential. This includes checking for leaks, ensuring the valve is free of debris, and testing the pressure settings periodically. Neglecting maintenance can lead to decreased performance and potential system failures, making it imperative to establish a routine inspection schedule.

Common maintenance tasks include:

Troubleshooting common issues, such as leaks or pressure inconsistencies, often involves inspecting seals and springs for wear and replacing them as needed. If a valve is not functioning properly, it is crucial to identify the root cause of the issue before attempting repairs. Common troubleshooting steps include:

By adhering to a rigorous maintenance schedule and being proactive in troubleshooting, operators can extend the life of Rexroth Pressure Relief Valves and ensure the continued safety and efficiency of hydraulic systems.

Rexroth Pressure Relief Valves are indispensable components in hydraulic systems, offering critical protection by maintaining pressure within safe limits. Their reliability and efficiency make them a preferred choice across various industries. By understanding their functionality, benefits, and maintenance needs, industries can ensure their systems remain safe and operational, maximizing both productivity and equipment longevity.

As technology continues to evolve, the design and capabilities of pressure relief valves are also advancing. Innovations in materials, smart sensing technologies, and integration with automated systems are paving the way for even more effective pressure management solutions. As industries seek to enhance their operational efficiency and safety, investing in high-quality components like Rexroth Pressure Relief Valves will remain a critical focus for future developments.

Ultimately, the role of these valves in preserving the integrity of hydraulic systems cannot be overstated. Their ability to respond to pressure changes promptly and reliably is paramount to the success of any operation that relies on hydraulic power. By prioritizing the selection, maintenance, and monitoring of pressure relief valves, industries can safeguard their investments and ensure a stable and efficient working environment.

In conclusion, the integration of Rexroth Pressure Relief Valves into hydraulic systems not only enhances safety but also contributes to improved operational efficiency and equipment longevity. As industries continue to innovate and adapt, the importance of these valves will only grow, underscoring the need for ongoing education and awareness regarding their function and maintenance. Embracing these principles will enable organizations to navigate the complexities of hydraulic system management effectively and sustainably.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!