The Rexroth Pwr10 is a cutting-edge power supply unit designed for optimal efficiency in industrial applications. As part of Rexroth's extensive portfolio, the Pwr10 exemplifies innovation in power management, catering to diverse sectors with its robust features. This article delves into the specifications, advantages, and applications of the Rexroth Pwr10, offering insights from industry experts to help you understand its impact on modern manufacturing processes.

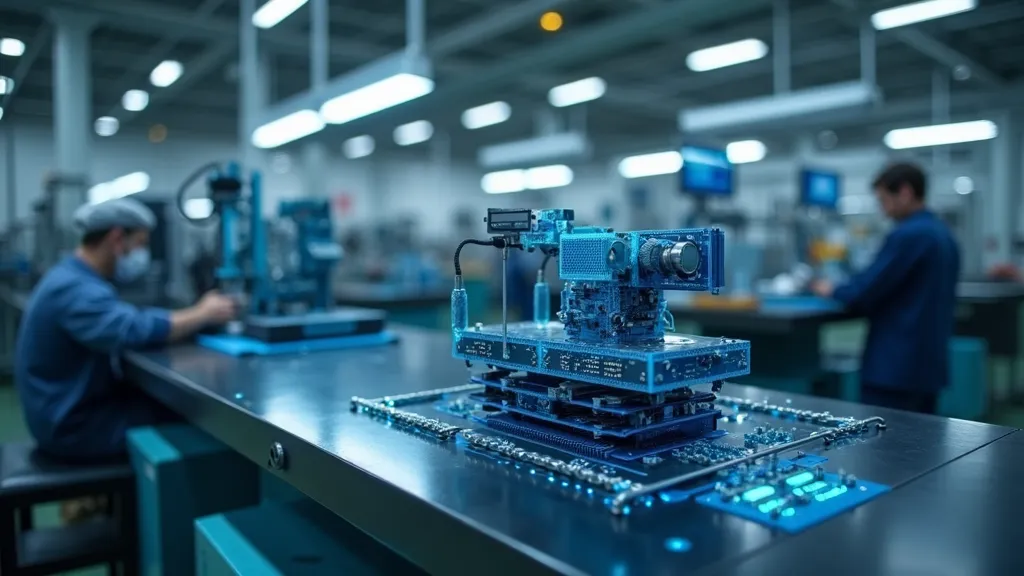

Industrial applications demand power solutions that are both reliable and efficient. The Rexroth Pwr10 stands out as a premier power supply unit within this domain, offering a blend of innovation and practicality. Designed by Bosch Rexroth, a leader in the field of drive and control technologies, the Pwr10 is built to meet the rigorous demands of modern manufacturing environments. This article provides a comprehensive analysis of the Rexroth Pwr10, highlighting its key features, benefits, and applications in the industry.

The Rexroth Pwr10 is engineered to deliver high performance under critical conditions. Its robust design ensures durability and longevity, making it a preferred choice for industries that require uninterrupted power supply. Key features of the Rexroth Pwr10 include:

The versatility of the Rexroth Pwr10 makes it suitable for a wide range of industrial applications. It is commonly used in sectors such as automotive manufacturing, aerospace, and heavy machinery. The unit's ability to provide consistent and reliable power makes it an essential component in operations where downtime is not an option. Additionally, the Pwr10's adaptability allows it to be customized for specific industry needs, further extending its applicability.

For instance, in the automotive industry, the Pwr10 is critical in powering robotic assembly lines, where precision and reliability are paramount. Its advanced monitoring features enable the detection of anomalies in power usage, ensuring that production lines remain operational without interruption. In the aerospace sector, where rigorous testing and validation processes are required, the Pwr10’s high efficiency and reliability ensure that testing equipment functions optimally, delivering accurate results.

Moreover, in heavy machinery, the Pwr10 can support various applications, from powering hydraulic systems to ensuring the smooth operation of complex machinery. Its scalability means that it can be tailored to fit different machinery specifications, which is crucial for manufacturers who constantly innovate and upgrade their equipment.

Industry experts underscore the importance of reliable power solutions in today's fast-paced manufacturing landscape. According to a recent report by IndustryWeek, efficient power management systems like the Rexroth Pwr10 can significantly reduce operational costs and improve productivity. Experts also highlight the role of advanced monitoring features in enabling predictive maintenance, thus enhancing the overall reliability of industrial equipment.

In discussions with engineers and production managers, many have noted that the ability to monitor equipment performance remotely has transformed how they approach maintenance. By utilizing the Pwr10’s advanced monitoring capabilities, teams can predict when a system might fail and schedule maintenance proactively, thus avoiding costly downtime.

Furthermore, the trend towards automation in manufacturing has increased the demand for power solutions that can keep up with the rapid pace of production. The Rexroth Pwr10, with its high efficiency and compact design, aligns perfectly with this trend, allowing manufacturers to automate processes without sacrificing power reliability.

| Feature | Rexroth Pwr10 | Competitor A | Competitor B |

|---|---|---|---|

| Efficiency | High | Moderate | High |

| Design | Compact | Bulky | Compact |

| Monitoring | Advanced | Basic | Advanced |

| Scalability | Excellent | Limited | Good |

This comparison highlights the Pwr10's competitive edge, particularly in areas such as efficiency and advanced monitoring. While some competitors may offer similar compact designs, the Pwr10's superior scalability and efficiency set it apart, making it a more appealing option for companies looking to future-proof their power solutions.

Q: What industries benefit from the Rexroth Pwr10?

A: The Rexroth Pwr10 is versatile and benefits industries such as automotive, aerospace, and heavy machinery, where reliable power supply is crucial. Additionally, sectors such as robotics, pharmaceuticals, and food processing also leverage its capabilities for various applications.

Q: How does the Rexroth Pwr10 improve operational efficiency?

A: It enhances efficiency through high power output with minimal losses and advanced monitoring for predictive maintenance. By allowing operators to address potential issues before they escalate, the Pwr10 helps maintain optimal performance levels.

Q: Can the Rexroth Pwr10 be integrated with existing systems?

A: Yes, its compact design and scalability make it ideal for integration into existing industrial setups. The Pwr10’s flexibility allows it to work seamlessly with various equipment, reducing the need for extensive modifications.

Q: What are the maintenance requirements for the Rexroth Pwr10?

A: The Pwr10 is designed for low maintenance. However, regular inspections and software updates are recommended to ensure optimal performance. The advanced monitoring features can also alert users to any maintenance needs, allowing for timely intervention.

Q: How does the Rexroth Pwr10 compare in terms of environmental impact?

A: The Pwr10 is designed with energy efficiency in mind, which not only reduces operational costs but also minimizes its environmental footprint. By consuming less energy and generating less waste heat, it contributes to more sustainable manufacturing practices.

The Rexroth Pwr10 stands as a testament to Bosch Rexroth's commitment to innovation and excellence in power management solutions. Its efficient, scalable, and reliable design not only meets but exceeds the expectations of modern industrial applications, ensuring uninterrupted operations and enhanced productivity.

Understanding the technical specifications of the Rexroth Pwr10 can provide deeper insights into its capabilities and suitability for various applications. Below are some key specifications:

Proper installation and configuration of the Rexroth Pwr10 are crucial for optimizing its performance. The installation process generally includes the following steps:

Real-world applications of the Rexroth Pwr10 demonstrate its effectiveness in various industrial settings. Below are a few notable case studies:

In a leading automotive manufacturing plant, the implementation of the Rexroth Pwr10 has streamlined operations in the assembly line. By replacing an older power supply system, the plant reported a 15% increase in productivity due to reduced downtime and enhanced equipment reliability. The advanced monitoring features allowed the maintenance team to anticipate equipment failures, leading to a more proactive maintenance approach.

An aerospace testing facility utilized the Pwr10 to power its range of testing equipment. The high efficiency of the Pwr10 ensured that tests were conducted without power interruptions, which is critical in aerospace development. As a result, the facility was able to shorten its testing cycles by 20%, accelerating the development of new aircraft components.

A construction company integrated the Rexroth Pwr10 into its fleet of heavy machinery. The scalability of the Pwr10 allowed them to customize power delivery for different machines, significantly improving fuel efficiency and reducing operational costs. With real-time monitoring, the company was able to track power usage and optimize machine performance, leading to a 25% reduction in energy costs.

As industries continue to evolve, so too do the requirements for power supply solutions. Several trends are emerging that may shape the future of power management, including:

In conclusion, the Rexroth Pwr10 power supply unit represents a significant advancement in industrial power management. With its combination of high efficiency, compact design, and advanced monitoring capabilities, it is well-suited to meet the demands of modern manufacturing environments. Its versatility across various applications—from automotive to aerospace—demonstrates its effectiveness in enhancing operational efficiency and productivity.

As industries continue to evolve, the Rexroth Pwr10 stands ready to adapt to future challenges, ensuring that businesses can maintain a competitive edge in a rapidly changing landscape. By investing in reliable power solutions like the Pwr10, companies can enhance their operational resilience and drive innovation in their respective fields.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!