This guide explores the intricacies and applications of the Rexroth Poppet Valve, a crucial component in hydraulic systems known for its reliability and performance. Originating from the renowned Bosch Rexroth AG, these valves are integral in various industries. Their design ensures efficient control of fluid flow, making them indispensable in complex machinery.

The Rexroth Poppet Valve is a key player in the realm of hydraulic systems. Manufactured by Bosch Rexroth AG, a leader in drive and control technologies, this valve is synonymous with precision and durability. Its primary function is to regulate the flow of fluid within hydraulic systems, making it an essential component in industries ranging from manufacturing to aerospace. The design and functionality of these valves not only enhance operational efficiency but also contribute to the safety and reliability of various systems. Understanding the mechanics of Rexroth Poppet Valves gives insight into their critical role in fluid dynamics and industrial applications.

Rexroth Poppet Valves are renowned for their robust design and high performance. These valves boast several features that enhance their functionality and reliability:

The versatility of Rexroth Poppet Valves allows them to be used in numerous applications, including:

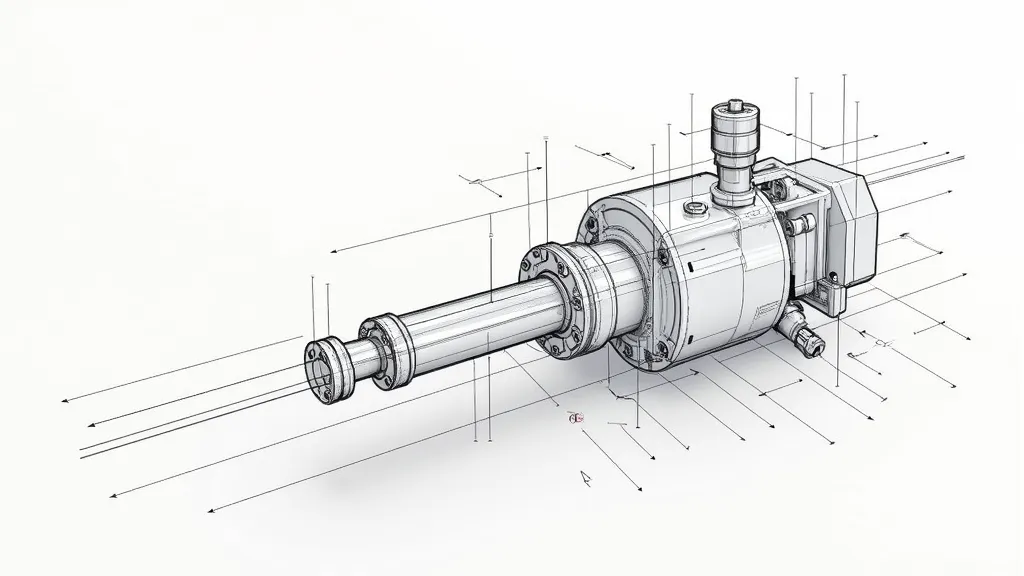

Understanding the operation of Rexroth Poppet Valves involves delving into their design and functionality. These valves operate by allowing or blocking fluid flow through the movement of a poppet, a small plug that seals against a valve seat. When actuated, the poppet moves away from the seat, permitting fluid to pass through. This design ensures that the flow can be precisely controlled, making it ideal for applications requiring exact fluid management.

The typical configuration includes a spring mechanism that holds the poppet in place until a certain pressure threshold is reached. Once this pressure is exceeded, the poppet lifts, allowing fluid to flow through the valve. This mechanism can be adjusted to vary the pressure at which the valve opens, providing flexibility in system design.

In addition to the basic operation, Rexroth Poppet Valves can be equipped with various actuation methods, including manual, pneumatic, or electric actuation, further enhancing their adaptability to different system requirements. These valves can also be integrated into more complex control systems, allowing for automated fluid management in sophisticated applications.

| Feature | Rexroth Poppet Valve | Other Hydraulic Valves |

|---|---|---|

| Durability | High resistance to wear and extreme conditions | Varies, often less durable under high pressure |

| Efficiency | Minimizes leakage, enhances system performance | May have higher leakage rates |

| Precision | Superior control of fluid flow | Can be less precise |

| Versatility | Wide range of applications | Often limited to specific uses |

| Actuation Options | Available in manual, pneumatic, and electric actuation | Limited options depending on the valve type |

| Maintenance | Requires minimal maintenance due to robust design | May require more frequent maintenance and servicing |

These valves are used in manufacturing, aerospace, automotive, marine, and construction industries due to their reliability and precision in fluid control. Their adaptability to various applications makes them a preferred choice in sectors where performance and safety are critical.

Their durability, efficiency, and precision make Rexroth Poppet Valves a preferred choice for systems requiring high performance and reliability. Additionally, their ability to handle extreme conditions and their versatility in application further solidify their place in various industries.

Yes, they are designed to handle extreme pressures and temperatures, making them suitable for harsh environments. Their materials and construction are engineered to withstand corrosion, wear, and fatigue, ensuring consistent performance in demanding conditions.

Yes, their compact design facilitates easy installation in existing systems, and their robust construction minimizes maintenance requirements. Regular inspections and basic maintenance can ensure optimal performance throughout their service life.

Choosing the right Rexroth Poppet Valve involves understanding your specific application requirements, including pressure ratings, flow rates, and environmental conditions. Consulting with a Rexroth representative or utilizing product catalogs can help you find a suitable valve tailored to your needs. It's also advisable to consider the actuation method based on your system's operation and control preferences.

The Rexroth Poppet Valve is a testament to advanced engineering and design in hydraulic systems. Its widespread use across various industries underscores its importance and reliability. As industries continue to evolve, the demand for such high-performance components will undoubtedly grow, solidifying Rexroth Poppet Valves as an integral part of modern industrial applications. With their proven track record of efficiency, durability, and precision, these valves will remain at the forefront of hydraulic technology, contributing to the advancement of automation and control in various sectors.

Furthermore, as technology progresses, the design and functionality of Rexroth Poppet Valves are likely to innovate, incorporating smart technologies and IoT capabilities. This evolution will enable better monitoring and control of hydraulic systems, further enhancing their performance and reliability in increasingly complex industrial environments. The future of Rexroth Poppet Valves appears promising, with ongoing advancements ensuring their relevance and effectiveness in an ever-changing landscape.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!