The Rexroth Pressure Relief Valve is a critical component in hydraulic systems, ensuring safety by controlling pressure levels. Known for its precision and reliability, this equipment is essential in various industries, from manufacturing to energy production. This article explores the functionalities, benefits, and expert insights into the application of Rexroth Pressure Relief Valves.

In the realm of hydraulic systems, the Rexroth Pressure Relief Valve stands out for its unmatched efficiency and reliability. These valves are designed to maintain safe pressure levels within hydraulic systems, preventing over-pressurization that could lead to equipment failure or safety hazards. This article delves into the intricate workings of these valves, their applications, and the benefits they offer to various industries. Understanding the critical role that Rexroth Pressure Relief Valves play in hydraulic systems is essential for engineers, technicians, and decision-makers who aim to optimize their hydraulic operations.

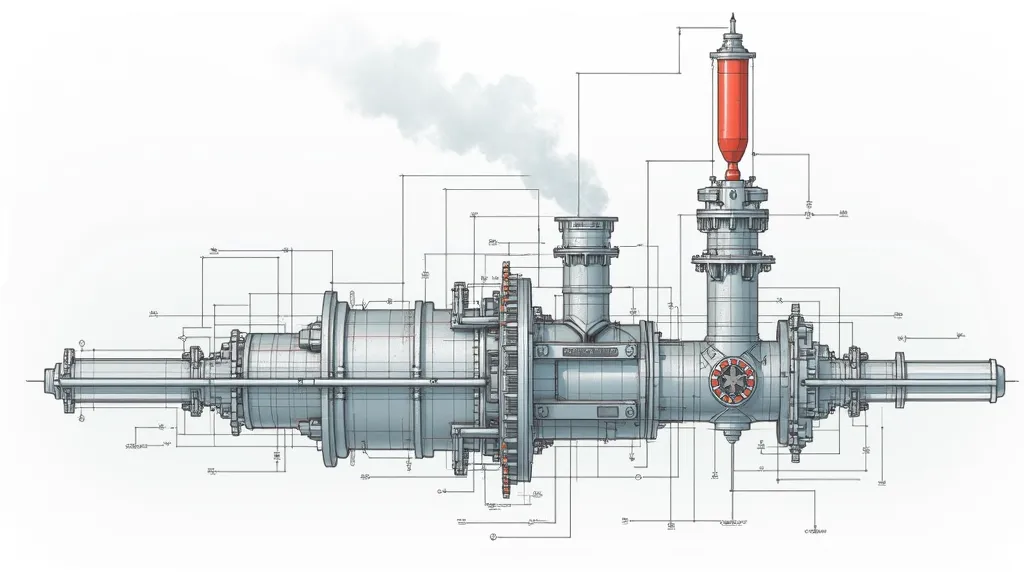

Pressure relief valves play a pivotal role in hydraulic systems by ensuring that the pressure does not exceed a predetermined level. The Rexroth Pressure Relief Valve operates by diverting excess fluid from the system when it reaches a critical pressure point, thus maintaining system safety and performance. This automatic operation is vital for preventing potential damage to the entire hydraulic system.

The basic principle behind the operation of these valves involves a spring-loaded mechanism that opens when the fluid pressure exceeds the set limit. The excess fluid is directed back to the reservoir or another part of the system, maintaining the desired pressure. This process not only protects the hydraulic components but also ensures that the system operates efficiently under varying load conditions.

Additionally, Rexroth Pressure Relief Valves can be equipped with various features such as adjustable pressure settings, integrated check valves, and remote monitoring capabilities. These enhancements allow engineers to tailor the valves to specific applications, ensuring maximum efficiency and safety. The ability to adjust pressure settings means that these valves can be fine-tuned for different operational needs, making them versatile tools in hydraulic system design.

One of the primary benefits of Rexroth Pressure Relief Valves is their precision in maintaining pressure levels. This precision translates to heightened safety and efficiency in operations, minimizing the risk of damage and downtime. Additionally, these valves are known for their durability and long lifespan, reducing the need for frequent replacements and maintenance. This reliability is particularly beneficial in industries where continuous operation is critical, such as manufacturing and energy production.

Moreover, Rexroth Pressure Relief Valves are designed with high-quality materials and advanced engineering techniques that enhance their performance under extreme conditions. For instance, they can withstand high temperatures and corrosive environments, which is essential for applications in industries like petrochemicals and marine operations. Their robust design ensures that they can handle not only the standard operational pressures but also unexpected spikes that could occur during system failures or sudden load changes.

Another significant advantage is their compact design, which allows for easier integration into existing hydraulic systems without requiring extensive modifications. This feature is especially valuable for retrofitting older systems where space may be limited. Furthermore, their low maintenance requirements contribute to reduced operational costs over time, making them a cost-effective choice for businesses looking to enhance their hydraulic systems.

Rexroth Pressure Relief Valves are utilized across a wide range of industries. In the manufacturing sector, they are essential in ensuring the smooth operation of machinery by preventing pressure build-up. This is particularly important in automated production lines where consistent pressure levels contribute to product quality and process efficiency. For example, in injection molding processes, maintaining precise pressure is critical for ensuring the integrity of molded parts.

In the energy sector, these valves help in maintaining the integrity of pipelines and other infrastructure by regulating pressure. They are commonly used in hydraulic fracturing and drilling operations, where controlling fluid pressure is vital for safety and operational success. Additionally, in renewable energy applications, such as wind turbines, pressure relief valves ensure that hydraulic systems that control blade pitch and yaw operate within safe limits, enhancing overall system reliability.

The automotive industry also significantly benefits from Rexroth Pressure Relief Valves. In hydraulic braking systems, these valves are vital for preventing brake fluid over-pressurization, contributing to vehicle safety. Similarly, in automotive assembly lines, they help maintain optimal pressure levels in hydraulic tools and machines.

Aerospace applications utilize these valves to ensure that hydraulic systems within aircraft operate safely under various conditions. Given the stringent safety regulations in this industry, the reliability of Rexroth Pressure Relief Valves is paramount. They are employed in landing gear systems, flight control surfaces, and cargo handling systems, where failure could result in catastrophic consequences.

In construction, hydraulic systems are indispensable for operating heavy machinery, and Rexroth Pressure Relief Valves are integral to ensuring these systems function safely. For example, in excavators and cranes, pressure relief valves help manage the hydraulic pressures that control lifting and digging operations, preventing accidents and equipment malfunctions.

Experts in hydraulic systems emphasize the importance of selecting the right pressure relief valve for specific applications. The choice of a Rexroth Pressure Relief Valve should consider factors such as the system's pressure requirements, flow rate, and operating environment. Professionals also highlight the importance of regular maintenance and inspection to ensure the valves function correctly and efficiently over time.

Moreover, industry experts suggest that businesses conduct thorough analyses of their hydraulic systems to determine the most suitable valve configurations. This may involve simulations and empirical testing to evaluate how different valves respond under varying conditions. By investing time and resources in this evaluation process, organizations can significantly enhance the reliability and safety of their hydraulic systems.

In addition, experts recommend that operators undergo training to understand the functionality and potential failure modes of pressure relief valves. Knowledgeable personnel can identify early signs of valve malfunction, such as unusual system behavior or fluctuating pressure readings, allowing for timely interventions that prevent larger issues from arising.

Another critical point made by industry professionals is the integration of advanced monitoring technologies with pressure relief valves. By utilizing sensors and IoT devices, companies can achieve real-time monitoring of pressure levels and valve performance. This data can be invaluable for predictive maintenance strategies, ensuring that any issues are addressed before they escalate into significant problems.

| Model | Pressure Range | Flow Capacity | Material |

|---|---|---|---|

| Rexroth PRV-100 | 0-250 bar | 150 L/min | Stainless Steel |

| Rexroth PRV-200 | 0-400 bar | 250 L/min | Carbon Steel |

| Rexroth PRV-300 | 0-600 bar | 350 L/min | Brass |

When comparing these models, it is essential to consider the specific requirements of your hydraulic system. For instance, the Rexroth PRV-100 is ideal for applications where lower pressure ranges are sufficient, such as in smaller hydraulic circuits or for controlling fluid flow in less demanding environments. Its stainless steel construction offers excellent corrosion resistance, making it suitable for applications in food processing or pharmaceuticals where hygiene is crucial.

On the other hand, the Rexroth PRV-200 provides a higher pressure range and flow capacity, making it suitable for medium to large hydraulic systems. The use of carbon steel in its construction offers a balance between strength and cost-effectiveness, making it a popular choice in industrial applications where budget constraints are a consideration.

Lastly, the Rexroth PRV-300 is designed for high-pressure applications, where robust performance is non-negotiable. Its brass construction contributes to its durability and resistance to wear, making it an excellent choice for heavy-duty operations in construction or mining sectors. Understanding the specifications and applications of each model allows operators to make informed decisions that optimize their hydraulic systems' performance.

The Rexroth Pressure Relief Valve is an indispensable component in maintaining the safety and efficiency of hydraulic systems. Its precision, reliability, and durability make it a preferred choice across various industries. By understanding their functionality and advantages, businesses can ensure optimal performance and safety in their operations. Regular maintenance and expert consultation can further enhance the lifespan and effectiveness of these critical components.

As industries continue to evolve and demand higher efficiency levels, the role of advanced hydraulic components like the Rexroth Pressure Relief Valve becomes even more crucial. By investing in quality valves and appropriate maintenance practices, companies can position themselves for success in an increasingly competitive landscape. Moreover, the integration of smart technologies with hydraulic systems opens new avenues for monitoring and optimization, further enhancing the capabilities of these vital components.

In conclusion, the importance of Rexroth Pressure Relief Valves in hydraulic systems cannot be overstated. They not only protect equipment but also contribute to the overall efficiency and reliability of operations across various sectors. As technology advances, the continuous development of these valves will ensure they meet the growing demands of modern applications, solidifying their status as a cornerstone of hydraulic systems worldwide.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!