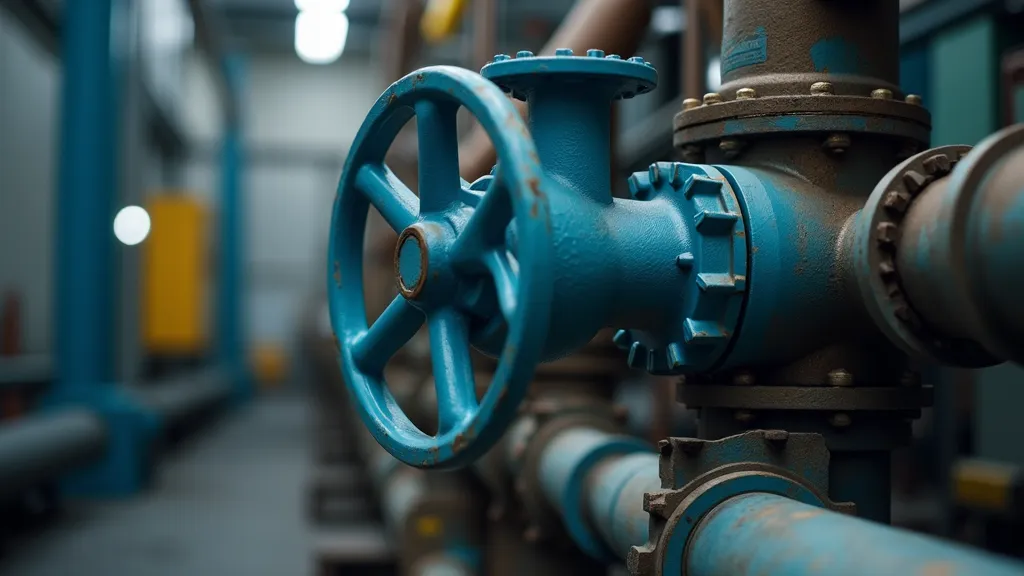

Rexroth Pressure Relief Valves are essential components in hydraulic systems, ensuring safe operation by managing excess pressure. These valves are renowned for their reliability and efficiency, suitable for various industrial applications. This article explores their functionality, benefits, and key considerations when selecting a Rexroth valve, offering a detailed understanding for industry professionals.

Rexroth Pressure Relief Valves play a crucial role in the safety and efficiency of hydraulic systems. By releasing excess pressure, these valves prevent potential damage to system components, ensuring smooth and uninterrupted operation. Known for their precision engineering and durability, Rexroth valves are a preferred choice in numerous industrial sectors, including manufacturing, construction, and energy. The significance of these valves cannot be understated; they serve as a first line of defense against overpressure conditions that could lead to catastrophic failures and costly downtime. Ensuring that these components are correctly specified and maintained is vital for the reliability of any hydraulic system.

Pressure relief valves are designed to protect hydraulic systems from exceeding designated pressure limits. When the pressure in a system surpasses the set threshold, the valve opens, allowing fluid to bypass the system or return to the reservoir. This mechanism not only safeguards equipment but also maintains optimal system performance. By providing a controlled release of pressure, these valves help to prevent burst hoses, damaged seals, and failing actuators that can lead to costly repairs and hazardous situations. The functionality of pressure relief valves is critical, especially in high-pressure applications where the consequences of failure can be severe.

In addition to their protective role, pressure relief valves also contribute to the overall efficiency of hydraulic systems. By relieving excess pressure, they help maintain stable operating conditions, which can improve the performance of hydraulic components such as pumps and actuators. This stability is essential for applications requiring precise control, such as in automated manufacturing processes or mobile machinery. Overall, the importance of pressure relief valves in hydraulic systems cannot be overstated; they are integral to ensuring safety, efficiency, and longevity in various industrial applications.

Rexroth valves are characterized by their robust construction and advanced technology. Key features include precise pressure control, quick response time, and minimal leakage, all of which contribute to enhanced system reliability. The precise pressure control capability ensures that the system operates within safe limits, preventing potential damage caused by overpressure. Quick response times are essential for dynamic applications where pressure can fluctuate rapidly, ensuring that the valve reacts promptly to changes in system pressure.

Moreover, minimal leakage is a critical feature of Rexroth valves, as it directly impacts system efficiency. Leakage can lead to a loss of hydraulic fluid, which not only affects performance but also increases operational costs. Rexroth has engineered their pressure relief valves to minimize this leakage, thereby enhancing the overall efficiency of the hydraulic system. Additionally, these valves are customizable to meet specific application requirements, ensuring they fit seamlessly into existing systems. Customizability includes variations in size, materials, and performance specifications, allowing engineers to tailor the valve to the unique demands of their applications.

| Model | Max Pressure (bar) | Flow Rate (l/min) | Material | Application |

|---|---|---|---|---|

| DR 6 DP | 315 | 60 | Steel | General Industrial Use |

| DBDS 10 K | 400 | 100 | Stainless Steel | High-Pressure Systems |

| DBW 20 B | 350 | 200 | Brass | Mobile Machinery |

| DB 25 C | 420 | 250 | Cast Iron | Heavy-Duty Applications |

| DBE 16 P | 300 | 80 | Aluminum | Lightweight Systems |

Rexroth pressure relief valves find application across a wide range of industries due to their versatility and reliability. Some of the most common applications include:

Rexroth Pressure Relief Valves are indispensable in maintaining the safety and efficiency of hydraulic systems. Their robust design, coupled with advanced technology, ensures optimal performance across various industrial applications. By considering key factors such as system pressure, flow rate, and environmental conditions, professionals can select the very suitable valve to meet their operational needs. Regular maintenance and adherence to installation guidelines further enhance the longevity and reliability of these critical components. As industries continue to evolve, the importance of reliable hydraulic components like Rexroth pressure relief valves will only increase, reinforcing their role as a cornerstone of modern hydraulic systems.

As technology advances, so do the features and capabilities of pressure relief valves. The future of Rexroth pressure relief valves is likely to include several trends that will enhance their functionality and adaptability in various applications. These trends are driven by the need for greater efficiency, reliability, and integration with modern automation systems.

One of the most significant trends shaping the future of pressure relief valves is the integration of Internet of Things (IoT) technology. Smart valves equipped with sensors can monitor pressure, temperature, and flow rates in real-time. This data can be transmitted to centralized monitoring systems, allowing for predictive maintenance and immediate alerts when parameters exceed safe limits. This advancement not only enhances safety but also helps in optimizing system performance by allowing for data-driven decision-making.

As industries face increasingly harsh operating conditions, the demand for pressure relief valves made from advanced materials will grow. Innovations in material science may lead to the development of valves that can withstand higher temperatures, corrosive environments, and wear over time. Additionally, advanced coatings may be applied to standard materials to improve their resistance to corrosion and friction, further extending the lifespan of the valves.

Energy efficiency is becoming a critical consideration in all industrial applications. Future Rexroth pressure relief valves are expected to incorporate design features that minimize energy loss, such as reduced internal leakage and optimized flow paths. These improvements will contribute to overall system efficiency, helping companies reduce operational costs and environmental impact.

The ability to customize and modularize pressure relief valves will likely become increasingly important as industries seek tailored solutions for unique challenges. Rexroth is expected to continue offering customizable options that allow engineers to specify particular features based on their operational requirements. Modular designs may also enable quick replacements and upgrades without the need for complete system overhauls, providing flexibility and scalability for evolving industrial needs.

In conclusion, Rexroth Pressure Relief Valves are vital components in hydraulic systems, ensuring safety and efficiency across numerous applications. As technology continues to evolve, so will the capabilities of these valves, with advancements in smart technology, material science, and energy efficiency paving the way for the next generation of hydraulic solutions. By staying informed about these trends and adhering to best practices in installation and maintenance, professionals can ensure the longevity and reliability of their Rexroth pressure relief valves, ultimately contributing to the success of their operations.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!