This article explores the significance of aerospace vibration isolators in maintaining the integrity and functionality of aerospace systems. Vibration isolators are critical components used in the aerospace industry to mitigate unwanted vibrations, ensuring the protection of sensitive equipment and improvement of system performance. The article delves into their fundamental role, types, applications, and the intricacies of choosing the correct vibration isolator for specific needs.

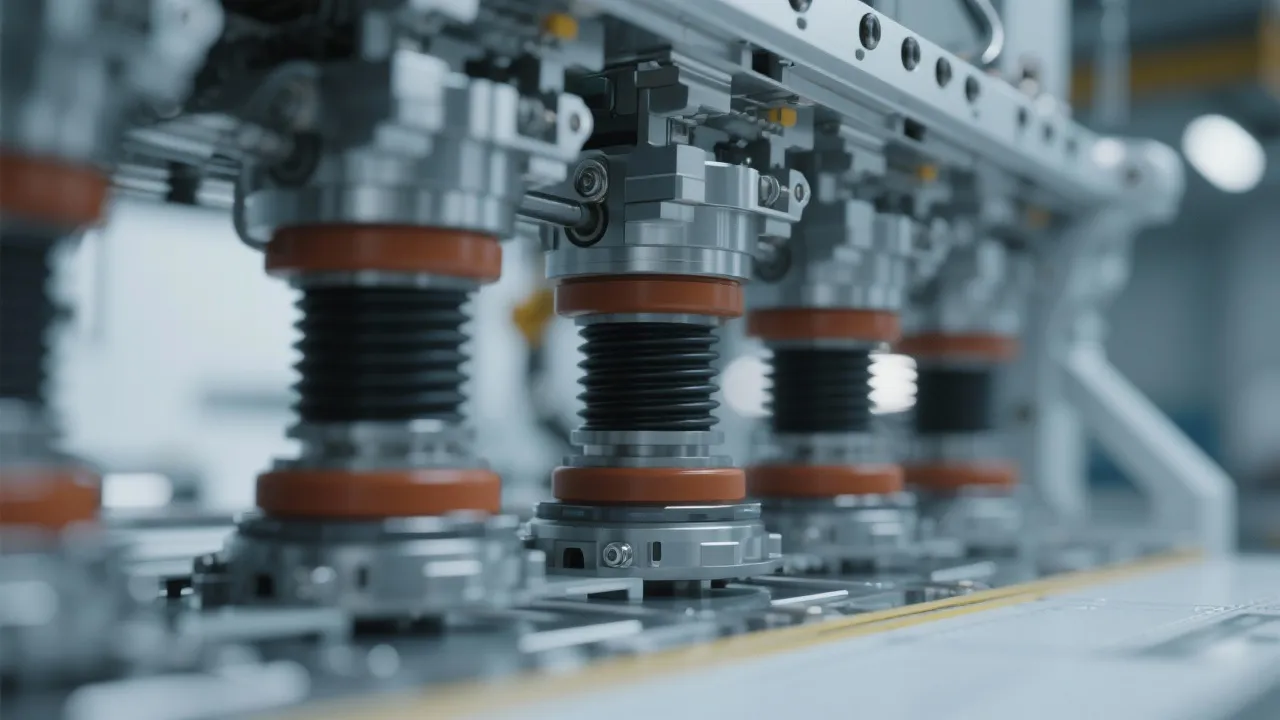

Aerospace vibration isolators are pivotal in ensuring the smooth operation of aerospace systems by mitigating challenging vibrations. These specialized components are engineered to absorb and neutralize the vibrations that could potentially compromise the performance and longevity of delicate and crucial aerospace equipment. Vibration isolators are instrumental across various applications, from small instrumentation panels to vast engine systems, helping to maintain the system's integrity and functionality. By effectively dampening unwanted oscillations, these isolators protect sensitive components from damage and ensure operational precision.

In the high-stakes environment of aerospace, maintaining stability and operational precision is paramount. Vibrations can be generated from numerous sources, including engine operations, aerodynamic forces, and external environmental factors. Left unchecked, these vibrations can lead to critical failures, affect the lifespan of components, and impair the performance of navigation, communication, and control systems. Thus, vibration isolators act as a safeguard, enhancing the reliability and efficiency of aerospace technology. They work by isolating and dampening the unwanted vibrational energy before it can impact other system components. This isolation minimizes the risk of mechanical failures that can arise from prolonged exposure to vibrations. Furthermore, maintaining structural integrity leads to the enhancement of overall safety in aviation operations.

The array of available vibration isolators can cater to an extensive range of requirements within the aerospace industry. These can be categorized into several types, each designed to fulfill specific functions and performance levels:

The selection process for an appropriate vibration isolator necessitates a thorough understanding of several key factors:

Vibration isolators find diverse applications within the aerospace industry, including:

According to industry experts, the effectiveness of an isolator depends heavily on its material properties, design precision, and operational adaptability. The science behind vibration isolation involves dynamics and kinematics principles, where the material's stiffness and damping characteristics are critical. Engineers must anticipate various operating conditions and potential failure modes to optimize every isolator's efficiency and reliability. The fundamental physics of vibration isolation encompasses not only the materials and designs employed but also the understanding of how these devices interact with both the vibrating system and the surrounding structural components. For instance, in some cases, the addition of dampers or tuned mass dampers alongside isolators may enhance performance by targeting specific vibrational frequencies for better overall attenuation.

| Type | Material | Pros | Cons |

|---|---|---|---|

| Elastomeric | Rubber, Silicone | Efficient damping, lightweight - excellent for smaller installations | Limited high-temperature range, can degrade over time |

| Metal Spring | Steel | High load capacity, durable, effective for heavy equipment | Possible resonance issues due to system harmonics |

| Wire Rope | Coiled Metal Cables | Shock resistant, versatile for dynamic loading conditions | Complex installation process can increase costs |

| Air Spring | Compressed Air System | Adjustable stiffness, adaptive to changing loads | Requires regular maintenance, susceptible to air leaks |

Q1: What distinguishes a good aerospace vibration isolator?

A good isolator is defined by its ability to efficiently dampen or absorb vibrations within the specified operational frequency and load ranges, its resilience to environmental factors, and its ease of integration into existing systems. Also, the manufacturing precision and consistency in material properties play pivotal roles in determining an isolator's overall performance.

Q2: How do aerospace vibration isolators contribute to safety?

By minimizing vibrations that can lead to mechanical failures, vibration isolators significantly enhance the safety and reliability of aerospace systems, ensuring smooth operation and extending the life span of critical components. This safety improvement also translates to fewer maintenance requirements and increased operational confidence during flight operations.

Q3: Is it possible to retrofit older aerospace systems with modern vibration isolators?

Yes, it is feasible to retrofit older systems. However, it requires an in-depth analysis of the existing setup and careful selection of isolators compatible with older designs and technology. Engineering assessments should consider the unique vibration profiles of the existing componentry to ensure effective retrofitting solutions.

The ongoing evolution of aerospace technology is driving significant advances in vibration isolation solutions. Emerging materials, such as smart polymers and composite materials, are being explored for their potential to enhance vibration isolation performance. These advanced materials can provide better energy damping characteristics while allowing for lighter and more compact designs. Innovations in manufacturing processes, including 3D printing, enable the rapid prototyping and customization of isolator designs, leading to tailored solutions for specific aerospace applications.

Moreover, advancements in sensor technology and IoT offer new possibilities in real-time monitoring of vibrations in aerospace systems. By integrating smart sensors within vibration isolators, real-time data can provide insights into isolator performance and predict failures before they occur. This predictive maintenance capability not only enhances safety but also optimizes operational efficiency by allowing preemptive adjustments or replacements before potential failures disrupt operations.

Several notable case studies illustrate the critical role that vibration isolators play in aerospace applications:

In a recent upgrade of a commercial airliner, the installation of advanced elastomeric isolators led to significant improvements in passenger comfort. Prior to the upgrade, passengers experienced discomfort due to vibrations transmitted through the fuselage, especially during takeoff and landing. The use of enhanced elastomeric isolators dramatically reduced these vibrations, leading to a smoother flight experience. Post-upgrade surveys indicated higher passenger satisfaction ratings and reduced complaints regarding cabin noise levels.

In military aviation, where operations are often conducted under extreme conditions, implementing wire rope isolators in the landing gear of a tactical aircraft resulted in enhanced operational reliability. The harsh environments faced during takeoffs and landings subjected aircraft components to severe stresses. The wire rope isolators absorbed significant shock and reduced vibrations experienced by the landing gear assembly, thereby enhancing the longevity of critical components and maintaining operational readiness.

In satellite technology, vibration isolators are indispensable for ensuring the precision of onboard instruments. A recent satellite deployment benefited from air spring isolators that allowed for adjustments in response to varying loads experienced during launch and orbital insertion. The adaptability of air spring systems significantly improved the stabilization of sensitive measurement instruments, leading to enhanced data collection accuracy.

The field of vibration isolation in aerospace is poised for tremendous growth and innovation. Ongoing research focuses on improving material properties for better damping efficiency, expanding the operational envelope for isolators, and investigating the long-term effects of various environmental conditions on isolator performance. Collaboration between academia and industry will be essential in driving advancements that not only enhance vibration isolation methods but also contribute to overall improvements in aerospace system designs.

In conclusion, aerospace vibration isolators play a crucial role in maintaining the reliability and effectiveness of aerospace systems. As the aerospace industry continues to evolve rapidly, the importance of selecting and using the correct vibration isolators cannot be overstated. From enhancing safety to improving operational performance, these devices are indispensable in navigating the complexities and challenges of aerospace technology. Furthermore, the integration of modern technologies and materials will continue to refine the efficiency and effectiveness of these isolators, ensuring that aerospace systems remain resilient and robust against the inevitable challenges posed by vibrations.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!