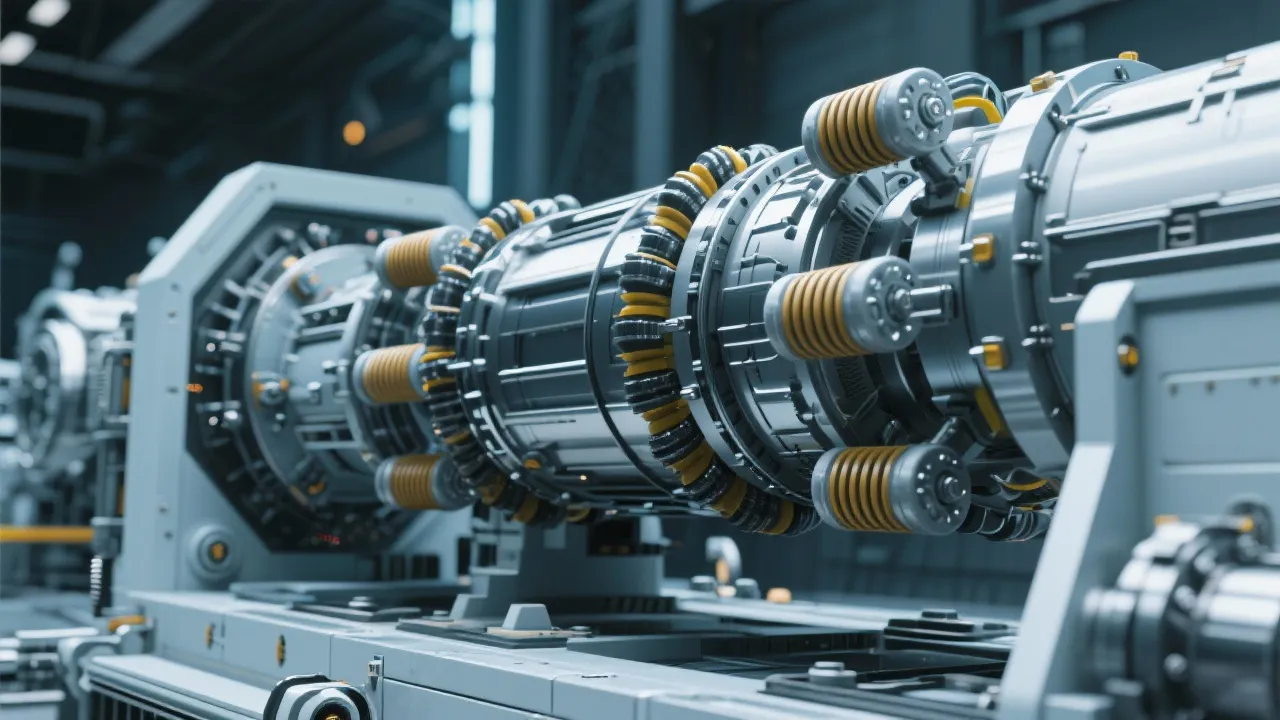

Aerospace vibration isolators are critical components designed to minimize vibration in aircraft. This article delves into their importance, functionality, and the latest advancements. These isolators ensure equipment within aircraft operates smoothly and reliably, enhancing both performance and passenger comfort by reducing noise and mechanical stress.

Aerospace vibration isolators are vital components in the aeronautical sector, engineered to curb the disruptive vibrations that aircraft experience during operation. These isolators are instrumental in ensuring the functionality and longevity of sensitive equipment embedded within aircraft structures. Given the complex dynamics of aircraft in operation, from takeoff to cruise and landing, the need for effective vibration isolation cannot be overstated. The interplay between vibrations and aerodynamics creates a unique environment where advanced engineering solutions, such as vibration isolators, play a crucial role.

Vibrations in aerospace contexts stem from various sources, including engine operations, aerodynamic forces, and mechanical interactions. Left unchecked, these vibrations can lead to accelerated wear and tear of components, increased noise levels, and potential failures in critical systems. This is where aerospace vibration isolators come into play, offering a buffer that absorbs and dissipates vibratory energy. The significance of isolators is not just limited to mechanical systems; it extends to passenger comfort and the overall safety of air travel. Uncontrolled vibrations can cause fatigue in the aircraft materials and critically influence the performance of onboard equipment.

Moreover, vibrations can cause resonance in structures, leading to catastrophic failure. As aircraft operate in environments where forces can lead to significant stress, the isolators serve a dual purpose: they mitigate potential structural damage while enhancing the operational integrity of systems such as control panels and navigation systems. As such, the integration of effective vibration isolation systems is a key consideration in the design phase of aircraft development.

Recent advancements in materials science have propelled the development of more effective aerospace vibration isolators. Contemporary isolators often utilize materials such as viscoelastic polymers and advanced composites that offer superior damping characteristics. Viscoelastic materials are especially beneficial due to their inherent ability to dissipate energy, which drastically reduces the transmission of vibrations. These materials are designed to provide maximal dampening with minimal added weight—an essential factor in aviation, where weight considerations directly impact fuel efficiency and operational cost.

In addition to viscoelastic polymers, researchers are exploring other innovative materials like shape memory alloys (SMAs) and piezoelectric materials that can react and adapt to dynamic changes in their environment. For instance, piezoelectric materials can generate an electrical charge when subjected to mechanical stress, which opens up possibilities for active vibration control systems that automatically adjust to changing frequencies and amplitudes of vibrations.

This shift towards smart and adaptive materials signifies a transformation in the design philosophy currently dominating aerospace engineering. It's not just about creating passive isolators anymore; rather, there’s a growing focus on systems that can actively respond and provide real-time solutions to vibration challenges.

Consider a scenario where an aircraft manufacturer implemented new vibration isolation technology. Utilizing composite materials with enhanced damping characteristics led to a 20% reduction in cabin noise, significantly improving passenger comfort. This innovation also translated to a prolonged lifespan for onboard electronics, minimizing maintenance costs and downtime. In this case, the manufacturer integrated lossy composites in the isolation mounts of their aircraft engines. The result was an astonishing enhancement in how vibrations were absorbed and managed, reducing not only the noise felt within the cabin but also improving the overall efficiency of the engine systems.

This case also highlights how passenger experience is becoming a focal point in aircraft design. As airlines increasingly recognize the importance of a comfortable travel experience, effective vibration isolation emerges as an essential feature. The relationship between vibration management and customer satisfaction is becoming more pronounced—airlines that invest in advanced isolator technologies are likely to stand out in a competitive market.

Additionally, the integration of these vibration isolator technologies resulted in less fatigue among crew members, enhancing their performance and safety. Reduced vibrations mean less disruption for pilots during critical flight operations, equating to a more stable control of the aircraft. Ultimately, this not only benefits the aircraft’s operations but also can lead to significant economic gains for the airline industry.

Selection of the right isolators depends on several criteria:

In addition to these criteria, it is essential to consider the specific application in which the isolators will be used. Different aircraft designs will have unique vibration characteristics based on their structure, engine design, and various operational conditions such as speed and altitude. Working with engineers who specialize in vibration analysis can help specify the optimal isolation solution for any given aerospace application.

Moreover, collaboration with manufacturers of vibration isolators can offer unique insights into how specific materials and configurations perform under different conditions. This partnership approach ensures that all aspects of vibration isolation are adequately addressed, facilitating a holistic understanding of engineering challenges and solutions in the aerospace sector.

The future of aerospace vibration isolators looks promising, with ongoing research into smart materials and the integration of active isolation systems that adapt in real-time to changing conditions. These innovations will likely offer unprecedented levels of protection and comfort, setting new standards in aerospace engineering.

As the aerospace industry continues to evolve, so will the technologies surrounding vibration isolation. The push for more eco-friendly and efficient designs—aligned with global sustainability initiatives—will drive the further adoption of lightweight and durable materials. Innovations in artificial intelligence and machine learning will likely lead to more sophisticated systems capable of predicting and dynamically responding to vibrational inputs, enhancing flight safety and performance.

Future research also promises to bring in a more sustainable approach to production and material sourcing, aiming for not just performance but also compostability and recyclability of isolator materials. Adopting such practices aligns with the industry-wide shift towards reducing carbon footprints and improving sustainability.

Overall, as the marriage of technology and materials science progresses, the potential for aerospace vibration isolators to impact the aerospace industry is immeasurable. Manufacturers who remain at the forefront of these advancements will undoubtedly produce the next generation of aircraft that are not only more efficient but also significantly safer and more comfortable for passengers and crew alike.

Information compiled based on data from industry reports and aerospace engineering studies, highlighting the ongoing research and technological advancements that are shaping the future of aerospace vibration isolators.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!