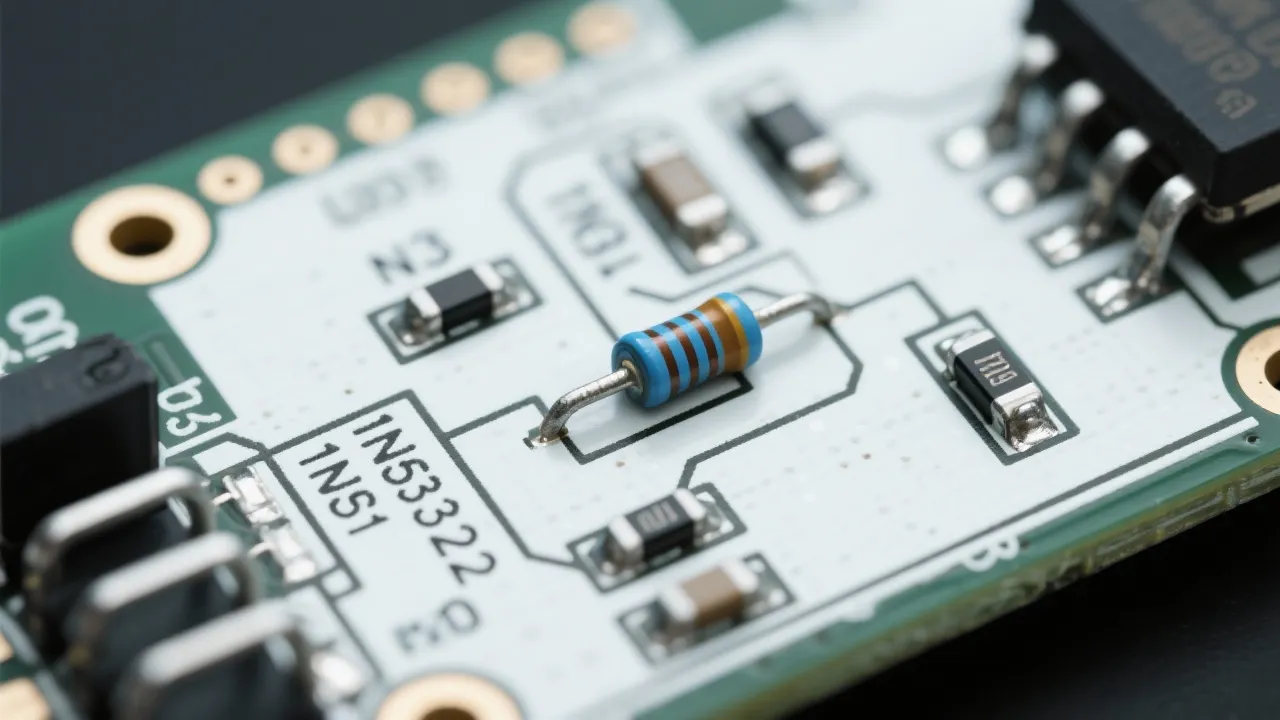

This article delves into the specifications and uses of the 1N5392 diode, a crucial component in ensuring current flow in electronic circuits. Primarily used for rectification purposes, the 1N5392 boasts a peak reverse voltage of up to 200V and can tolerate forward currents of up to 1.5A. Here, we will explore its applications, compare it with similar components, and examine the conditions under which it operates optimally.

The 1N5392 diode is a staple in electronic circuits, renowned for its ability to maintain unidirectional current flow under various voltage conditions. Its primary function lies in rectification, helping convert alternating current (AC) to direct current (DC), which makes it essential for power supply systems and electronic devices that derive their power from AC sources. Diodes in this category are often utilized to ensure the proper flow of electrical energy, preventing damage to sensitive components. The ability of the 1N5392 to withstand high levels of current and voltage underpins its popularity and versatility, making it a key component in a multitude of electronic applications.

Understanding the technical specifications of the 1N5392 diode is crucial for any electronics professional or hobbyist involved in circuit design. Here are some of its key specifications:

The specifications above highlight the robustness of the 1N5392 diode. Its maximum repetitive reverse voltage of 200V enables it to handle a range of applications, from consumer electronics to industrial systems. The forward continuous current rating of 1.5A allows for effective current management in regular operating conditions, while its non-repetitive peak forward surge current capability means it can tolerate brief spikes during operation without succumbing to damage. This feature is particularly important in applications where the current may fluctuate unexpectedly. Additionally, the operating temperature range indicates that the 1N5392 can function reliably across a variety of conditions, which is essential for devices that may experience overheating.

The 1N5392 diode is widely used in various applications thanks to its robust performance under high-voltage conditions. Commonly found in power supply systems, it serves as a rectifying diode in adapters and power modules. Its high surge tolerance is crucial in circuits with substantial inrush currents, such as those found in motor drives, switching power supplies, and battery chargers. Furthermore, the 1N5392 is implemented in the following applications:

The diverse range of applications for the 1N5392 showcases its importance in electronic circuitry, where reliable performance is paramount.

In the realm of diodes, the 1N5392 is often compared with its peers, such as the 1N5400 and 1N4007 diodes. Here's a comparative analysis to elucidate their similarities and differences:

| Diode | Max Voltage | Max Current | Special Features |

|---|---|---|---|

| 1N5392 | 200V | 1.5A | High surge capability |

| 1N5400 | 50V | 3A | Higher forward current capacity |

| 1N4007 | 1000V | 1A | Higher voltage applications |

The 1N5400, for example, has a higher forward current capacity compared to the 1N5392, making it suitable for applications where higher current ratings are required, even though it can only withstand a maximum of 50V. This diode is often used in low-voltage power supply applications where current demand is significant. On the other hand, the 1N4007 is designed for high-voltage applications where its voltage rating of 1000V allows it to be utilized in rectifying circuits for various high-voltage power supplies and industrial electronics.

In contrast, the 1N5392 strikes a balance between voltage and current handling, allowing it to be versatile across multiple applications. Engineers frequently select the diode based on specific circuit requirements, and understanding the nuances between these diodes can lead to more effective circuit designs.

For optimal performance, the 1N5392 diode should be used within its specified limits. Ensuring that the diode is not exposed to voltages exceeding its rating is critical to prevent breakdowns. Moreover, adequate heat dissipation measures, such as heat sinks, should be implemented in designs involving continuous high current flow. When designing circuits, it is essential to consider the reverse recovery time of the diode, particularly in switching applications, as this can affect efficiency and performance.

Another key factor that can influence the diode's performance is the arrangement of the components in the circuit. Close proximity to heat-generating devices should be avoided to minimize thermal stress. Proper layout can mitigate thermal hotspots, which may otherwise lead to premature failure of the diode.

Additionally, routine maintenance checks are advisable in systems that utilize the 1N5392 diode extensively. Regular inspections can help identify signs of wear or potential failure, facilitating timely replacements before critical failures occur, thereby ensuring continuous operation of the system without interruptions.

Testing diodes such as the 1N5392 can be performed using a digital multimeter (DMM), oscilloscope, or specialized semiconductor testers. A straightforward method to test the diode is to check its forward and reverse bias characteristics:

These tests help ensure that the diode is functioning correctly, and any deviations from expected readings should raise a flag for replacement or further investigation.

For more sophisticated assessments, an oscilloscope can be utilized to observe the diode's switching behavior, providing insights into its response times and efficiency in dynamic conditions. Examining the diode's performance in real-time under various load conditions helps in gauging its reliability across different operational scenarios.

Integrating the 1N5392 diode into circuit designs requires a thorough understanding of the circuit requirements. This includes determining the voltage and current ratings, identifying potential inrush currents, and integrating suitable protection measures. Here's how to effectively integrate the diode:

Proper integration and attention to circuit design nuances allow for maximizing the efficiency and performance of the 1N5392 diode, ensuring reliability and functionality across a variety of applications.

The efficiency of the 1N5392 diode can be compromised by a variety of factors that may lead to issues like thermal runaway, excessive leakage, or total failure. Here are some common issues encountered with diodes and troubleshooting methods for each:

In addition, it may be useful to maintain records of testing and repairs to develop a trend analysis over time. Documenting parameters that lead to premature diode failures can assist in future design improvements, ensuring better component selection and longer operational life.

The 1N5392 diode remains an integral component within the electronics landscape. Its ability to handle significant electrical loads while protecting circuits from reverse voltage disruptions underscores its reliability. For designers and engineers, understanding the nuances of its operation is essential to optimize its use in various applications. Additionally, as electronics continues to evolve, the relevance of robust and versatile components like the 1N5392 will persist, making it a critical consideration for ensuring modern devices perform effectively and reliably. Each application can benefit from exploring the practical attributes and testing the limits of this diode, leading to innovative circuit designs that harness its capabilities.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!