This guide provides an in-depth exploration of conical inductors, essential components in modern electronic circuits. Conical inductors offer distinct advantages such as improved frequency performance and compact design, making them critical in high-frequency applications. This article delves into their structure, benefits, applications, and practical considerations for integration into electronic systems.

Conical inductors are a specialized type of inductor, characterized by their conical-shaped coil. This unique design enables them to handle higher frequencies and provide better performance in certain applications compared to traditional cylindrical inductors. The conical shape allows for a gradual change in inductance, which can be beneficial for impedance matching and reducing signal loss in high-frequency circuits. As technological advancements push the boundaries of electronic devices, the role of conical inductors becomes increasingly important, especially in areas like telecommunications, RF design, and compact electronics.

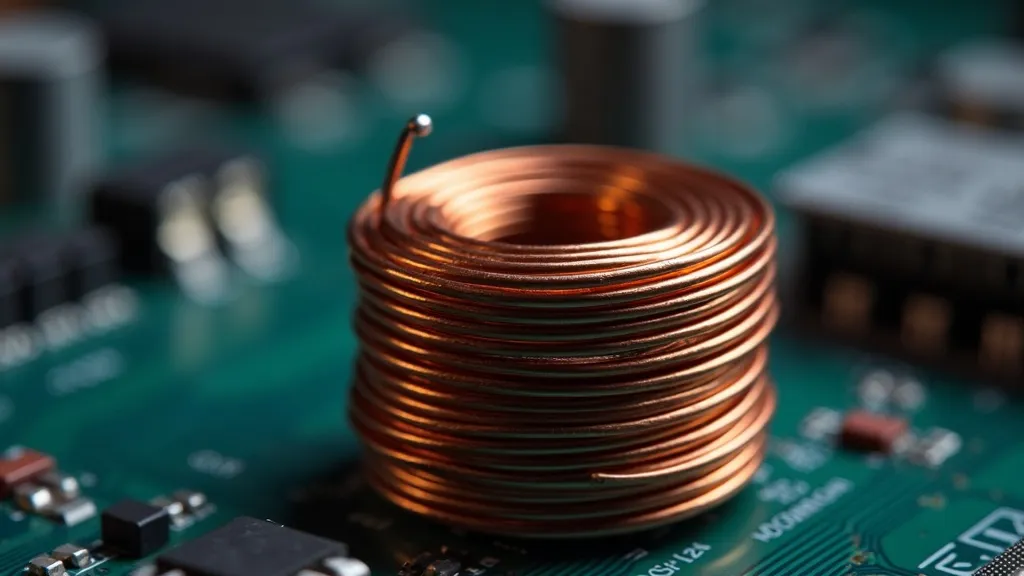

The conical inductor's structure features a coil that is wound in a conical shape, usually made from copper or another conductive material. This design allows for a more compact form factor, which is advantageous in modern electronics where space is often at a premium. The conical shape helps in distributing the inductance more evenly, which can lead to improved quality factors (Q) and reduced parasitic capacitance. The coil's tapering creates a more gradual change in the magnetic field, which contributes to its ability to handle higher frequencies without significant losses.

In addition to copper, other materials such as aluminum and specialized alloys can be used depending on the application requirements. The choice of material affects not only the electrical properties but also the thermal characteristics of the inductor. For instance, inductors used in high-power applications might require materials that can withstand higher temperatures without degrading performance. Furthermore, the winding technique can vary; for instance, some manufacturers may use advanced winding methods to reduce losses even further, ensuring that the inductors maintain their performance over time.

Conical inductors offer several advantages over traditional inductors, especially in high-frequency applications. These include:

Conical inductors are employed in a variety of applications, particularly where high-frequency performance is critical. Common uses include:

When integrating conical inductors into electronic systems, several factors must be considered to ensure optimal performance:

| Inductor Type | Advantages | Disadvantages |

|---|---|---|

| Conical Inductor | Improved high-frequency response, compact design, better impedance matching | Potentially higher cost compared to traditional inductors |

| Cylindrical Inductor | Cost-effective, widely available, good for low-frequency applications | Larger size, limited high-frequency performance, more susceptible to parasitic capacitance |

| Toroidal Inductor | Efficient magnetic field containment, lower electromagnetic interference (EMI) | Complex manufacturing process, can be bulky for certain applications |

| Air Core Inductor | No core losses, high-frequency performance | Low inductance values, larger size required for higher inductance |

Conical inductors represent a significant advancement in inductor technology, offering enhanced performance in high-frequency applications. Their unique design and advantages make them a valuable component in modern electronic systems. As engineers continue to push the limits of electronic circuit design, the importance of understanding the characteristics, advantages, and applications of conical inductors cannot be overstated. By leveraging their unique properties, designers can create more efficient and reliable electronic devices that meet the demands of today’s fast-paced technological landscape.

Furthermore, as the demand for compact, high-performance electronics grows, the role of conical inductors is expected to expand, driving innovation in their design and application. Future developments may include advancements in materials technology, such as the use of superconductors or advanced composites, which could further improve the performance characteristics of conical inductors. The ongoing research in this field suggests a promising horizon for conical inductors, ensuring their relevance in the continually evolving world of electronics.

In summary, conical inductors are not just another component; they are a crucial part of the electronic design landscape, enabling high-frequency performance and compact designs that are essential for modern applications. As we look to the future, understanding and integrating these inductors into various electronic systems will be key to achieving optimal performance and reliability.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!