This comprehensive guide explores the conical inductor, an essential component in modern electronics. Known for its unique shape and efficient electromagnetic properties, the conical inductor is pivotal in improving signal integrity and performance in various applications. By examining its design, uses, and benefits, this article provides valuable insights into its role in contemporary technological advancements.

The conical inductor, a staple in the realm of electronics, is renowned for its distinctive tapered shape, which offers superior performance characteristics compared to traditional inductors. This guide delves into the fundamental aspects of conical inductors, shedding light on their design, functionality, and applications in today's technological landscape. The conical inductor serves a pivotal role in managing electrical energy efficiently, and its unique geometry allows for enhanced performance in various applications. As we explore the intricacies of conical inductors, we will uncover the science behind their design and operation, revealing why they are increasingly favored in contemporary electronics.

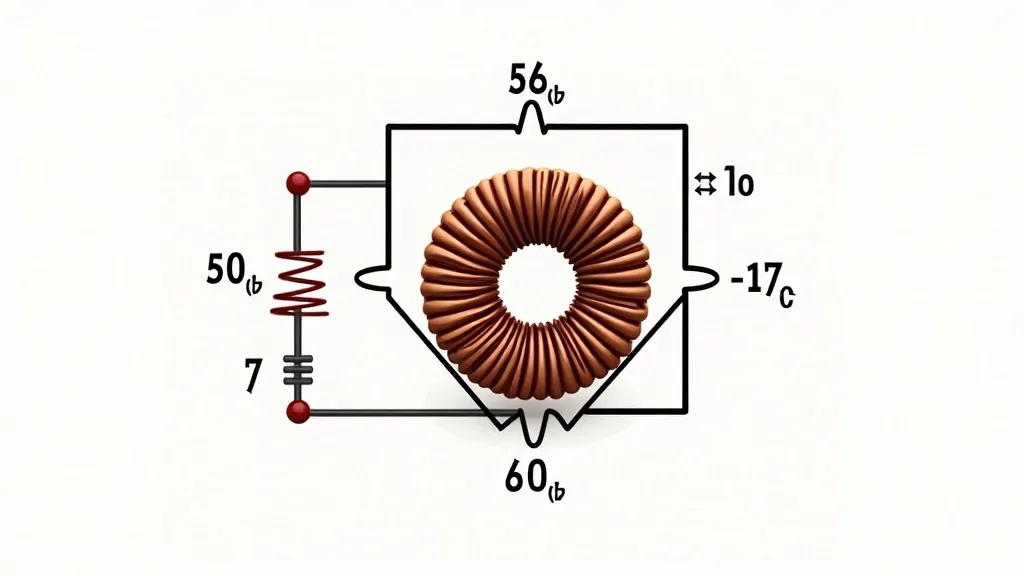

Conical inductors are characterized by their cone-like structure, which provides several advantages over standard cylindrical or toroidal inductors. The gradual increase in coil diameter from one end to the other enhances the inductor's ability to handle higher current and minimize electromagnetic interference. This unique geometry also contributes to a broader range of inductance values, making conical inductors versatile components in various electronic applications. Their design allows for the efficient storage and release of energy, which is critical in applications requiring rapid changes in electrical current. The optimization of magnetic fields within the inductor further contributes to their efficiency, making them a preferred choice in high-frequency operations.

Conical inductors find their use in numerous fields, owing to their efficiency and adaptability. They are commonly employed in RF circuits, communication devices, and power supplies, where maintaining signal integrity is crucial. Their ability to handle high-frequency signals with minimal loss makes them ideal for advanced applications in telecommunications and wireless technology. Beyond traditional applications, conical inductors are also utilized in automotive electronics, medical equipment, and consumer electronics. For instance, in automotive systems, they are employed to manage power in electric vehicles, ensuring efficient energy use and improved performance. In medical devices, they can help in signal processing, where precision and reliability are paramount. Furthermore, as the Internet of Things (IoT) expands, the demand for compact and efficient inductors such as conical inductors grows, allowing for the development of smarter and more capable devices.

The design of a conical inductor involves meticulous planning to ensure it meets specific electrical requirements. The manufacturing process typically includes winding a conductive wire around a conical core, often made from ferrite or other magnetic materials. This careful construction allows for precise control over the inductor's properties, such as inductance, resistance, and quality factor. The winding technique is crucial; it can influence the magnetic field distribution and inductance value. Different winding methods, such as bifilar or trifilar winding, can be used to optimize the inductor for specific applications. Additionally, advancements in materials science have led to the development of high-performance insulating materials that further enhance the inductor's operational capabilities. The selection of core material is also a pivotal aspect, as it significantly affects the inductor's saturation current rating and overall efficiency. Modern manufacturing techniques, including computer numerical control (CNC) machining and automated winding systems, enable the production of highly precise conical inductors, catering to the growing demands of various industries.

One of the primary benefits of conical inductors is their ability to operate efficiently at high frequencies, reducing power loss and improving overall circuit performance. Their compact size and lightweight nature make them ideal for modern electronic devices, where space and weight are critical considerations. Additionally, their design minimizes parasitic capacitance, further enhancing their functionality in high-speed applications. The reduced parasitic effects lead to improved signal fidelity, making conical inductors suitable for sensitive applications like audio processing and high-speed data transmission. Moreover, their ability to handle large currents without significant heat generation is a crucial feature for power applications, allowing for designs that are both compact and thermally efficient. As more electronic devices become miniaturized, the need for efficient inductors that can perform without compromising on size or performance becomes increasingly important.

| Feature | Conical Inductor | Traditional Inductor |

|---|---|---|

| Shape | Conical | Cylindrical/Toroidal |

| Frequency Handling | High Frequency | Varies |

| Size | Compact | Variable |

| Parasitic Capacitance | Low | Higher |

| Applications | RF, Telecommunications | General Electronics |

The comparison above highlights the distinctive features and advantages of conical inductors over traditional inductors. Their unique shape and design enable them to achieve performance metrics that often surpass those of their cylindrical or toroidal counterparts. As the demand for high-frequency components continues to rise, conical inductors are becoming increasingly popular in applications where efficiency and size are paramount. The ability to fabricate conical inductors with customized inductance values and high precision allows engineers to design systems that meet specific performance criteria, further solidifying their role in modern electronics.

Q: What is the main advantage of a conical inductor?

A: The main advantage of a conical inductor is its ability to efficiently handle high-frequency signals with minimal power loss, making it ideal for RF and telecommunications applications. The reduction in electromagnetic interference also enhances signal clarity and integrity.

Q: How does the shape of a conical inductor affect its performance?

A: The conical shape allows for a gradual increase in coil diameter, which enhances current handling capabilities and reduces electromagnetic interference, leading to improved performance. This shape also contributes to a more uniform magnetic field distribution, which is crucial for maintaining inductance stability across varying frequencies.

Q: In what applications are conical inductors very commonly used?

A: Conical inductors are very commonly used in RF circuits, communication devices, and power supplies where maintaining signal integrity is crucial. They are also finding their way into integrated circuit designs, where their compact form factor and performance characteristics align with the needs of modern microelectronics.

Q: Are there any limitations to using conical inductors?

A: While conical inductors offer numerous advantages, their design complexity and manufacturing costs may be higher compared to traditional inductors, which can be a consideration for some applications. Additionally, their performance can be sensitive to environmental factors such as temperature and humidity, which may affect the core material's magnetic properties.

In summary, conical inductors are vital components in the advancement of modern electronics, offering a unique blend of performance, efficiency, and adaptability. Whether enhancing communication systems or powering high-frequency applications, these inductors are instrumental in pushing the boundaries of technology. As the demand for more efficient and compact electronic components grows, the role of conical inductors will undoubtedly continue to expand, solidifying their place in the future of electronic design. With ongoing advancements in materials and manufacturing techniques, the potential for conical inductors in new applications is vast. The exploration of new core materials, such as nanocrystalline and amorphous alloys, may further enhance their performance and efficiency, paving the way for innovative designs that meet the challenges of future electronic systems.

The future of inductor technology is poised for significant advancements, particularly with the growing trend towards miniaturization and efficiency in electronic devices. As industries continue to seek smaller, lighter, and more energy-efficient components, the demand for innovative inductor designs, including conical inductors, is likely to increase. Research is ongoing into materials that can withstand higher temperatures and offer better magnetic properties, which will enhance the performance of conical inductors even further.

In addition, the integration of inductors into printed circuit boards (PCBs) is becoming more prevalent. This approach not only saves space but also allows for improved performance due to reduced lead lengths and lower parasitic effects. As PCB technology advances, we can expect more designs that incorporate conical inductors directly into the board layout, leading to more compact and efficient systems.

The rise of electric vehicles (EVs) and renewable energy sources also presents new opportunities for conical inductors. In EV applications, inductors are crucial for the efficient management of power conversion systems, including inverters and chargers. Conical inductors can help minimize losses during these processes, contributing to longer battery life and improved vehicle range. Furthermore, their role in renewable energy systems, such as solar inverters and wind turbine controllers, will likely expand as the world shifts towards more sustainable energy solutions.

Research and development efforts focused on improving inductor technology are crucial for the continued evolution of electronic systems. Universities and research institutions are investigating new designs and materials to enhance the performance of inductors. This includes exploring the use of superconducting materials that can eliminate resistive losses, potentially revolutionizing the efficiency of inductors at high frequencies.

Moreover, the use of simulation tools and advanced modeling techniques has become increasingly important in the design process of conical inductors. These tools allow engineers to predict the behavior of inductors under different operating conditions, leading to more optimized designs. The integration of machine learning algorithms into the design and testing phases could further expedite the development process and lead to the discovery of novel inductor configurations.

As we look to the future, conical inductors are set to play a pivotal role in the advancement of electronic technology. Their unique advantages in handling high frequencies, compact design, and efficiency make them indispensable in various applications from telecommunications to automotive systems. The continuous evolution of materials and manufacturing processes will ensure that conical inductors remain at the forefront of innovation in the electronics industry.

In conclusion, understanding the complexities and benefits of conical inductors is essential for engineers and designers as they navigate the challenges of modern electronics. By leveraging the unique properties of these inductors, the industry can push the boundaries of what is possible, leading to the development of more efficient, compact, and powerful electronic devices that will shape the future of technology.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!