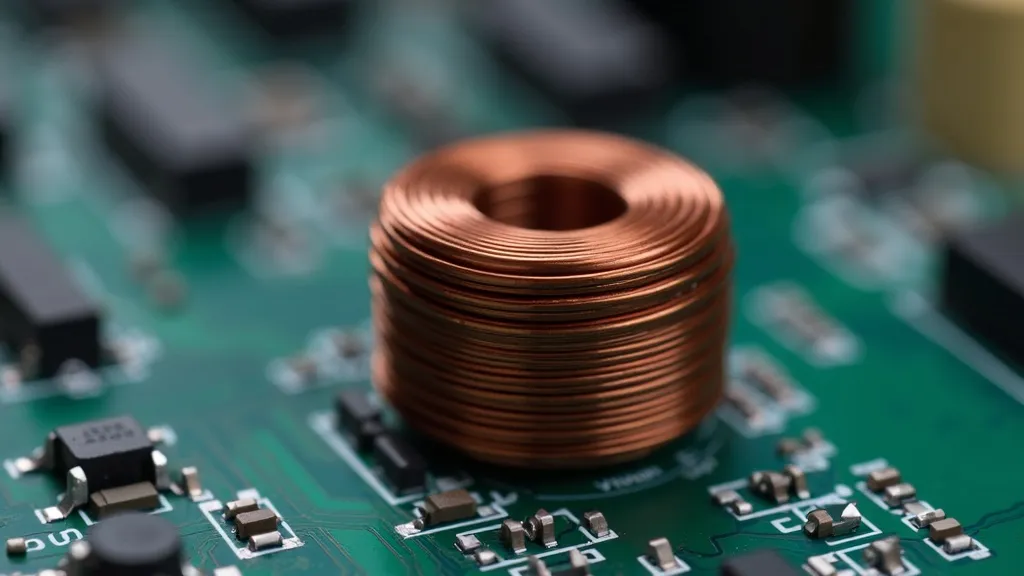

Conical inductors are vital components in modern electronics, offering unique advantages for high-frequency applications. These inductors are designed with a tapered coil, enhancing performance in RF and microwave circuits. Their distinct geometry provides a broader frequency range and improved impedance matching, making them indispensable in advanced electronic design.

Conical inductors play a crucial role in the realm of electronics, particularly in applications requiring high-frequency performance. Unlike traditional inductors, conical inductors feature a coiled wire wound in a cone shape. This unique configuration allows for improved performance in terms of frequency response, impedance matching, and thermal management. The distinctive geometry of conical inductors not only optimizes their electromagnetic properties but also contributes to enhanced self-resonance characteristics, making them a preferred choice in many high-performance circuits.

Primarily used in RF (radio frequency) and microwave applications, conical inductors are favored for their ability to handle a wide range of frequencies. The tapered design results in a gradual change in inductance, which is beneficial for achieving optimal impedance matching across different components of an electronic system. This capability is essential in reducing signal reflection and ensuring efficient power transfer. Moreover, the conical shape can significantly reduce the overall size of the inductor while maintaining its performance, making it suitable for compact devices where space is at a premium.

Conical inductors are extensively used in wireless communications, radar systems, and satellite technology. Their ability to operate efficiently at high frequencies makes them ideal for these advanced technologies. In wireless communications, for example, conical inductors are utilized in transmitters and receivers where maintaining signal integrity is crucial. Additionally, they are instrumental in test equipment and other precision devices where signal integrity is paramount.

One of the key benefits of using conical inductors is their thermal management capabilities. The geometry of the inductor promotes better heat dissipation, which is vital in high-power applications. This characteristic minimizes the risk of overheating, ensuring the longevity and reliability of electronic devices. Furthermore, their compact size and ability to integrate into multilayer circuit boards make conical inductors an attractive option for modern electronic designs, where miniaturization is a significant trend.

| Inductor Type | Advantages | Applications |

|---|---|---|

| Conical Inductor | Wide frequency range, improved impedance matching, better thermal management | RF circuits, microwave technology, compact devices |

| Cylindrical Inductor | Simplicity, ease of manufacturing, cost-effective | General electronic circuits, power applications |

| Toroidal Inductor | Low electromagnetic interference, high inductance-to-volume ratio | Power supplies, audio equipment, filter circuits |

Experts in the field highlight the importance of selecting the right inductor based on specific application needs. According to industry specialists, conical inductors provide an edge in scenarios where space constraints and thermal effects are critical considerations. Their compact shape and efficient heat dissipation further enhance their suitability for dense circuit designs.

In a recent seminar on advanced electronic components, leading engineers emphasized the evolving nature of inductor technology. They noted that as frequencies increase in RF applications, traditional designs may struggle to meet performance metrics. Conical inductors, with their unique shape, have been shown to outperform cylindrical and toroidal inductors in high-frequency scenarios, leading to more reliable and high-quality signal transmission.

Moreover, the experts discussed the ongoing research into materials used in manufacturing conical inductors. Innovations in ferrite materials and conductive polymers are paving the way for even better performance characteristics, such as reduced core losses and enhanced thermal stability. This research is crucial as it ensures that conical inductors can keep pace with the demands of next-generation communication technologies.

While conical inductors offer numerous advantages, they also present challenges in terms of manufacturing precision and cost. The intricate design requires advanced manufacturing techniques to ensure consistency and reliability. Moreover, the materials used must withstand high-frequency operations without compromising performance. The production of conical inductors often involves specialized winding methods and stringent quality control processes, which can drive up costs compared to more traditional inductor designs.

Additionally, the design and simulation phase can be quite complex. Engineers must consider various factors, including the inductance value, Q factor, self-resonant frequency, and thermal performance, when designing a conical inductor. This multifaceted approach requires sophisticated modeling tools and expertise, which may not be readily available in all engineering teams.

Another challenge lies in the integration of conical inductors into existing circuit designs. While their benefits can significantly enhance performance, ensuring compatibility with other components and the overall circuit layout can be a daunting task. Engineers must often iterate on designs multiple times to achieve optimal performance while accommodating the unique characteristics of conical inductors.

As technology continues to evolve, the demand for efficient and versatile components like conical inductors is expected to grow, making them an integral part of future innovations. The ongoing development in semiconductor technology, particularly in the realm of high-frequency and high-power applications, will drive the need for advanced inductor designs. Conical inductors, with their unique properties, are well positioned to meet these emerging challenges.

One of the most promising trends is the integration of conical inductors into integrated circuits (ICs). As miniaturization continues to be a focus in electronics, the ability to embed inductors directly within semiconductor devices can lead to significant improvements in performance and space savings. Researchers are actively exploring methods to fabricate conical inductors at the micro and nano-scale, which could revolutionize their use in a wide array of applications.

Additionally, advancements in materials science are opening new avenues for improving the performance of conical inductors. The development of high-temperature superconductors, for instance, could lead to inductors with drastically reduced losses, enabling them to operate at higher frequencies and power levels than currently possible. This could have profound implications for telecommunications, power systems, and even quantum computing.

Furthermore, the rise of the Internet of Things (IoT) and 5G technologies is expected to create new demands for inductive components that can handle the increasing complexity and speed of modern communications. Conical inductors, with their superior performance characteristics, may play a pivotal role in the development of next-generation wireless devices and systems.

In conclusion, the conical inductor is a pivotal element in the advancement of electronic technology, especially in areas requiring high precision and performance. Their unique design offers distinct advantages in terms of frequency response, impedance matching, and thermal management, making them suitable for a wide range of applications, particularly in RF and microwave technology. As research and development continue to push the boundaries of what is possible in electronics, conical inductors will likely remain at the forefront of innovation, driving enhancements in communication, power management, and overall device efficiency.

As industries increasingly prioritize miniaturization and performance, the role of conical inductors will only become more significant. The challenges they present in terms of manufacturing and design must be addressed through ongoing technological advancements and collaboration among engineers, material scientists, and manufacturers. Together, these efforts will ensure that conical inductors continue to meet the evolving needs of the electronics industry, paving the way for new innovations and applications that will shape the future of technology.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!