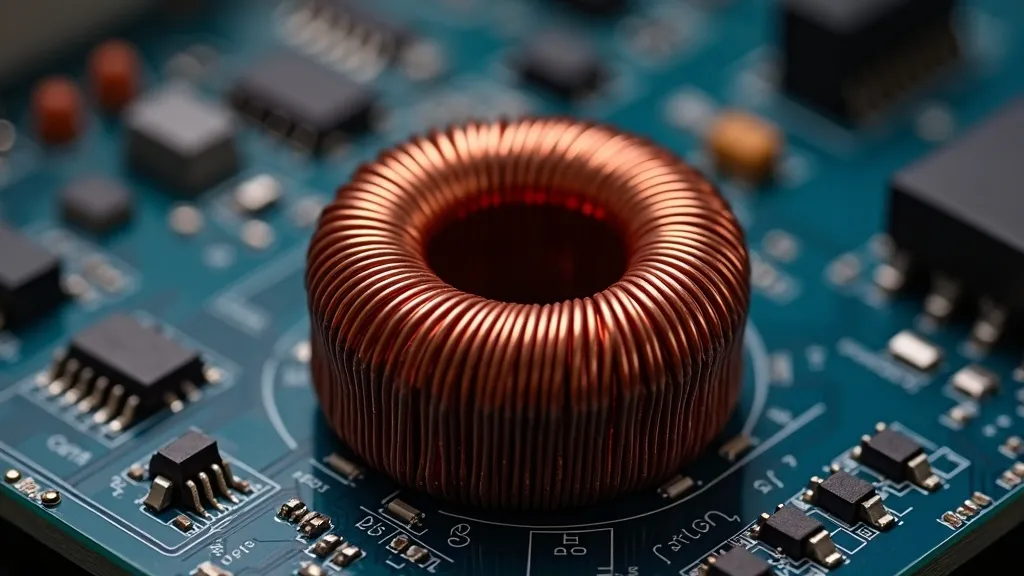

This article delves into the intricacies of the conical inductor, a vital component in modern electronics known for its unique shape and efficiency. Conical inductors are designed to handle high frequencies with minimal loss, making them essential in RF and microwave applications. We explore their construction, applications, and benefits, offering insights from industry experts to provide a comprehensive understanding.

Conical inductors are a specialized type of inductor characterized by their cone-shaped coil. This unique geometry makes them highly efficient for applications requiring high-frequency performance, such as RF and microwave systems. The conical shape allows for reduced parasitic capacitance and improved Q factor, which are crucial for maintaining signal integrity in high-speed communication systems. Their unique configuration offers advantages over traditional cylindrical inductors, particularly in minimizing losses and optimizing performance at elevated frequencies. Furthermore, as technology advances, the relevance of these components in modern electronic design continues to grow.

The design of a conical inductor involves a tapered coil winding, which is often made from copper or another conductive material. The tapering of the coil reduces the overall size and weight of the inductor while enhancing its ability to manage high-frequency signals effectively. The core material of a conical inductor is typically chosen based on the desired frequency range and application, with ferrite and powdered iron being common choices. These materials are selected for their magnetic properties that resonate well with the operating frequency, thus ensuring optimal energy storage and transfer.

In terms of construction, the winding process is critical. The coil is often wound in a way that ensures a uniform distribution of current across its length. This uniformity helps to minimize the inductance variation that can occur due to uneven current distribution, which can lead to inefficiencies and signal distortion. Moreover, the choice of insulation and shielding is also essential in the design process, particularly in high-frequency applications where electromagnetic interference (EMI) can significantly affect performance. Proper insulation not only protects the wire but also maintains the integrity of the inductor's performance.

Additionally, advanced manufacturing techniques have been developed to enhance the performance of conical inductors. For example, the use of computer-aided design (CAD) software allows engineers to simulate the inductors' performance before they are built, optimizing the design for factors such as inductance value, Q factor, and core losses. These simulations can identify potential issues with the inductors' performance, allowing for adjustments to be made before physical prototypes are created. Furthermore, automated winding machines have improved the consistency and precision of the winding process, leading to higher quality inductors.

Conical inductors are used in a variety of applications where high performance at high frequencies is necessary. These include RF amplifiers, oscillators, filters, and impedance matching networks. Due to their ability to handle significant power levels and maintain a stable inductive reactance, they are also prevalent in wireless communication devices, satellite systems, and radar equipment. Each of these applications presents unique challenges that conical inductors are well-suited to address.

In RF amplifiers, for example, conical inductors help ensure that the amplifier can handle high-frequency signals without distortion. They are often used in conjunction with other components like transistors to create a robust signal path that can amplify weak signals for transmission. In oscillators, the precision of the inductance value is crucial for maintaining the desired frequency output, and the high Q factor of conical inductors allows for stable oscillation without unwanted harmonics.

Filters, another critical application, utilize conical inductors to selectively pass certain frequency ranges while blocking others. This capability is essential in communications, where different channels must be isolated from one another to prevent interference. Impedance matching networks benefit from the compact size and high performance of conical inductors, enabling efficient power transfer between different stages of a circuit. Moreover, the high-frequency characteristics of conical inductors make them ideal for use in high-speed digital applications such as data converters and high-frequency switching power supplies.

More recently, conical inductors have found applications in emerging technologies. For instance, they are being integrated into 5G communication systems, where the demand for higher bandwidth and lower latency requires advanced components that can operate effectively at millimeter-wave frequencies. Additionally, in the realm of Internet of Things (IoT) devices, where size constraints are often significant, the compact nature of conical inductors allows for their integration into miniature devices without compromising performance.

The primary benefits of conical inductors are their excellent high-frequency performance and compact size. Their design minimizes energy loss and distortion, ensuring a clean and reliable signal. Additionally, the reduced parasitic elements result in a higher quality factor, which is essential for applications requiring precise signal processing. This quality factor, or Q factor, is a measure of how effectively an inductor can store energy; a higher Q factor indicates lower energy losses and improved efficiency.

Another significant advantage is their thermal stability. Conical inductors can operate over a wide temperature range without significant degradation of performance, making them suitable for applications in harsh environments. This characteristic is particularly important in automotive and aerospace applications, where components are frequently exposed to extreme conditions.

Moreover, the manufacturing process for conical inductors can be optimized for cost efficiency. While the initial investment in specialized materials and winding techniques may be higher than traditional inductors, the long-term benefits of reduced energy losses and improved performance can justify the costs. Additionally, as the demand for high-frequency components continues to grow, advancements in manufacturing technologies are likely to drive down costs, making conical inductors even more accessible for various applications.

Experts in the field of electronics emphasize the importance of conical inductors in advancing technology. According to a report by TechInsights, the global market for RF components, including conical inductors, is expected to grow significantly over the next decade due to increasing demand for faster and more reliable communication systems. Renowned engineer Dr. Emily Chang notes, "The conical inductor is an unsung hero in high-frequency applications, offering unparalleled performance in a compact form factor." This sentiment is echoed by various industry leaders who recognize that as electronic devices become more complex, the role of effective passive components like inductors cannot be overstated.

Furthermore, industry conferences and seminars have begun to highlight the advancements in inductor technology, with a focus on conical designs. Researchers and engineers from leading universities and companies are collaborating to explore new materials and designs that can enhance the performance of conical inductors even further. This includes the investigation of new core materials that can provide better magnetic properties and thermal stability, as well as innovative winding techniques that can improve efficiency and reduce production costs.

Additionally, with the rise of electric vehicles (EVs) and renewable energy systems, the demand for high-performance inductors in power conversion applications is increasing. Conical inductors are being studied for their potential to improve the efficiency of power inverters and converters used in these technologies, underscoring their versatility and importance across multiple sectors.

| Feature | Conical Inductor |

|---|---|

| Shape | Conical |

| Frequency Range | High frequencies, typically RF and microwave |

| Applications | RF amplifiers, oscillators, filters, impedance matching networks |

| Core Material | Ferrite, Powdered Iron |

| Benefits | High Q factor, Reduced parasitic capacitance, Compact size |

| Thermal Stability | Excellent over wide temperature ranges |

| Cost Efficiency | Higher initial costs but potential for long-term savings |

Q: What makes conical inductors suitable for high-frequency applications?

A: Their unique shape reduces parasitic capacitance and enhances the Q factor, which is crucial for maintaining signal integrity at high frequencies. The design also allows for better control over the magnetic field, which is essential for efficient energy transfer at high speeds.

Q: Can conical inductors be used in low-frequency applications?

A: While primarily designed for high frequencies, they can be used in low-frequency applications if the design parameters are adjusted accordingly. However, the advantages of the conical design may not be fully realized in lower frequency ranges, where traditional inductors might perform just as well or better.

Q: How does the core material affect the performance of a conical inductor?

A: The core material influences the inductor's frequency range and efficiency. Ferrite is often used for higher frequencies due to its low loss characteristics, while powdered iron is suitable for broader frequency ranges, offering a compromise between performance and cost. The choice of core material can also affect the inductance value, saturation current, and overall thermal performance.

Q: Are there any limitations to using conical inductors?

A: The primary limitation is their cost, which can be higher than standard inductors due to their specialized design. Additionally, they may not be necessary for applications that do not require high-frequency performance. Furthermore, the complexity of their design may lead to longer lead times for production, which can be a consideration for manufacturers under tight deadlines.

In conclusion, the conical inductor is a critical component in the realm of high-frequency electronics. Its innovative design and exceptional performance make it indispensable for advanced communication systems. As technology continues to evolve, the demand for these components is expected to rise, further solidifying their role in the future of electronics. As we look toward the future, ongoing research and development in the field of inductors promise to uncover even more applications and enhancements, ensuring that conical inductors remain at the forefront of electronic design innovation.

As the landscape of electronics continues to shift with the advent of new technologies, the development of conical inductors is poised to keep pace with these changes. Emerging trends such as the rise of 5G technology, Internet of Things (IoT) devices, and electric vehicles are driving the need for more efficient, compact, and high-performance inductors. Engineers and researchers are actively exploring innovative materials and designs that could further enhance the capabilities of conical inductors.

One area of focus is the exploration of new core materials that could provide better magnetic properties. For instance, researchers are investigating the use of composite materials that combine the advantages of different substances, such as ceramics and metals, to create cores that exhibit superior performance in terms of loss characteristics and thermal stability. This could lead to conical inductors that not only perform better at high frequencies but also operate efficiently under a wider range of environmental conditions.

Another promising avenue for development is the integration of conical inductors with other passive components in a single package, often referred to as system-in-package (SiP) technology. This approach could lead to more compact designs that save space on printed circuit boards (PCBs) while improving overall performance. By combining inductors with capacitors and resistors, designers can create highly efficient circuits that minimize signal loss and enhance functionality in a small footprint.

Furthermore, advances in manufacturing technologies, such as additive manufacturing (3D printing), could revolutionize the production of conical inductors. This method allows for highly precise control over the shape and material composition of inductors, potentially leading to designs that were previously impossible to fabricate. The ability to customize inductors to fit specific application requirements could open up new markets and use cases, expanding the role of conical inductors even further.

As we look towards the future, it is clear that conical inductors will continue to play a vital role in the advancement of electronic technologies. Their unique properties and performance characteristics make them indispensable in high-frequency applications, and ongoing research and development efforts will ensure that they remain relevant in an ever-evolving technological landscape. The integration of new materials, manufacturing techniques, and innovative designs will likely yield even greater efficiencies and capabilities, solidifying the conical inductor's position as a cornerstone of modern electronics.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!