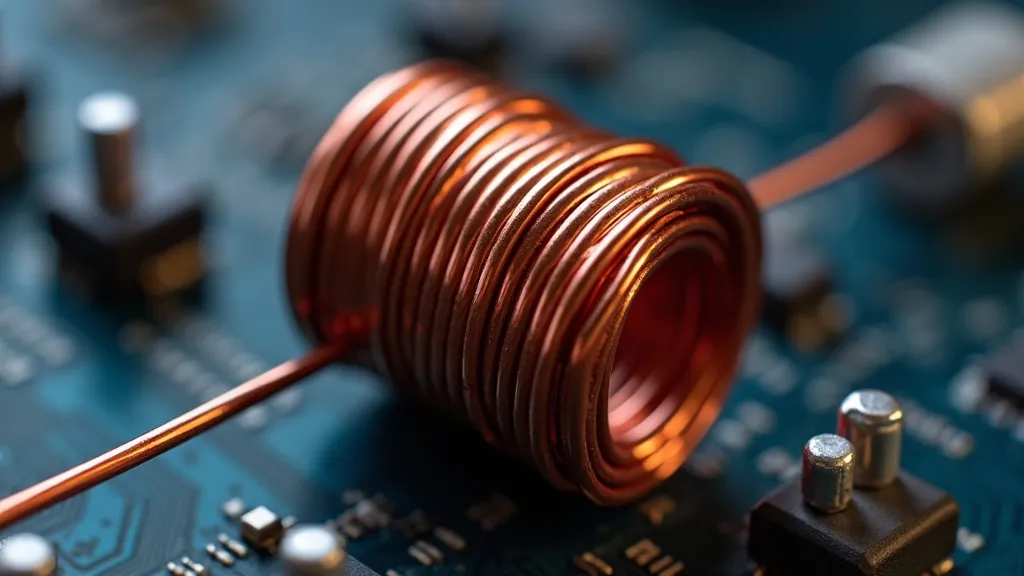

This guide explores the significance of conical inductors in modern electronics. Conical inductors are specialized components used to manage electromagnetic interference and optimize signal integrity in circuits. Their unique shape allows for superior performance in high-frequency applications, making them essential in various technological advancements.

Conical inductors, recognized for their distinctive tapered design, have become indispensable in the realm of electronics. These components are engineered to handle high-frequency applications, providing enhanced performance in various electronic devices. Due to their ability to manage electromagnetic interference (EMI) and maintain signal integrity, conical inductors are integral in advancing modern technology. The growing demand for efficient and reliable components in fast-paced consumer electronics, telecommunications, and industrial applications has further propelled the adoption of conical inductors.

The conical inductor's unique shape is not just for aesthetics; it is a strategic design choice that allows for a gradual increase in inductance. This design improves the inductor's ability to handle higher frequencies and provides a wide bandwidth. The tapered structure reduces the magnetic field's intensity at the inductor's base, minimizing losses and enhancing efficiency. As a result, conical inductors are particularly suited for applications requiring precise frequency management, such as in RF circuits and broadband solutions. Moreover, the conical shape allows for a more compact design compared to traditional cylindrical inductors, making them suitable for space-constrained applications.

In terms of materials, conical inductors are often constructed from ferrite cores or air cores, depending on the specific application requirements. Ferrite cores are commonly used for higher inductance values and improved magnetic performance, while air cores are favored for high-frequency applications due to their lower losses. The choice of wire gauge and winding technique is also critical; often, Litz wire is employed to reduce skin effect losses at high frequencies, ensuring that the inductor operates efficiently across its intended range.

Conical inductors are prevalent in various sectors of electronics. In telecommunications, they are used in mobile devices to manage signal integrity and reduce interference. Their ability to operate efficiently at high frequencies makes them ideal for advanced wireless communication systems. In addition to cellular technology, conical inductors play a vital role in satellite communications, where maintaining signal clarity and minimizing latency is paramount.

Additionally, they find applications in automotive electronics, particularly in systems requiring precise control and high reliability. Features such as electronic stability control, advanced driver-assistance systems (ADAS), and infotainment systems leverage conical inductors to ensure optimal performance. The automotive industry's shift towards electric vehicles (EVs) and hybrid systems further emphasizes the importance of these inductors, as efficient energy management becomes crucial for battery performance and longevity.

Furthermore, conical inductors are increasingly utilized in medical devices, where precision and reliability are critical. Devices such as MRI machines and ultrasound equipment rely on these inductors to ensure accurate signal processing and imaging capabilities. The aerospace and defense sectors also benefit from the robustness and efficiency of conical inductors, especially in navigation systems and radar technology.

| Feature | Conical Inductors | Traditional Inductors |

|---|---|---|

| Frequency Handling | High-frequency applications | Limited to lower frequencies |

| Design Efficiency | Tapered to minimize losses | Standard design with potential losses |

| Applications | RF circuits, broadband solutions | Basic electronic applications |

| Size | Compact design for space-constrained applications | Bulkier, less adaptable to compact designs |

| Material Versatility | Customizable with ferrite or air cores | Often limited to specific core types |

When integrating conical inductors into a design, several factors must be considered. The specific frequency requirements of the application will dictate the inductor's size and material. Additionally, the operating environment, including temperature and potential interference sources, should be assessed to ensure optimal performance. Engaging with reputable suppliers who can provide detailed specifications and customization options is crucial for achieving the desired outcomes.

Another critical aspect to consider is the inductor's current rating. Overloading an inductor can lead to overheating and potential failure, so it is essential to ensure that the inductor is rated appropriately for the application's current demands. Furthermore, the inductor's Q factor, which indicates its efficiency, should be evaluated, particularly in high-frequency applications where losses can significantly impact overall performance.

Designers should also be aware of the layout of the circuit board when incorporating conical inductors. The placement of inductors can influence the overall electromagnetic compatibility (EMC) of the device. Proper spacing between inductors and other components, along with appropriate grounding techniques, can mitigate issues related to crosstalk and EMI. Utilizing simulation tools during the design phase can help predict performance and identify potential problems before physical prototyping.

Conical inductors represent a significant advancement in the field of electronics, offering enhanced performance in high-frequency applications. Their unique design and functionality make them an essential component in modern technology, from telecommunications to automotive systems. By understanding their advantages and implementation considerations, engineers and designers can effectively harness their potential to improve electronic device performance.

As technology continues to evolve, the demand for more sophisticated and efficient inductors will only grow. Future innovations may lead to even more refined designs of conical inductors that push the boundaries of frequency handling and efficiency. Research into new materials, manufacturing techniques, and integration methods will further enhance their applicability across various industries.

Moreover, the increasing complexity of electronic systems, coupled with the demand for miniaturization, underscores the importance of conical inductors. Their adaptability to various applications ensures that they will remain relevant in the design of next-generation electronic devices. As we advance into an era characterized by rapid technological advancement, understanding and leveraging the capabilities of conical inductors will be essential for engineers and manufacturers alike, paving the way for innovative solutions in electronics.

In summary, conical inductors are not just a component of electronic systems; they are a key driver of performance and reliability in a rapidly changing technological landscape. Their unique characteristics make them invaluable in high-frequency applications, and their ongoing development will likely lead to even greater advancements in electronic design and functionality, ensuring that they remain at the forefront of modern electronics.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!