This guide delves into the role and functionality of conical inductors in electronic circuits. Conical inductors are specialized components used to manage electromagnetic interference and enhance performance in various electronic applications. The article explores their design, applications, and advantages in modern technology, providing a comprehensive understanding for industry professionals.

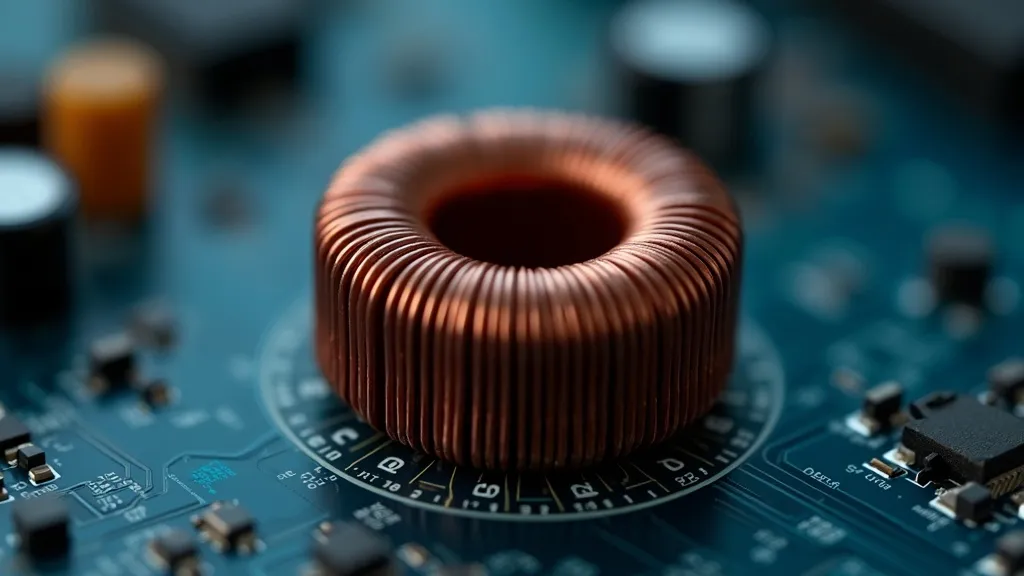

In the realm of electronics, inductors play a crucial role in managing electrical currents and enhancing circuit performance. Among various types, conical inductors stand out for their unique design and specialized applications. These inductors, characterized by their cone-shaped coil, are pivotal in managing electromagnetic interference (EMI) and improving signal integrity across different electronic systems.

Inductors, in general, are passive electrical components that store energy in a magnetic field when electrical current flows through them. The conical design of these inductors is particularly beneficial, offering advantages in terms of efficiency and performance in high-frequency applications. Their geometric shape allows for a unique magnetic field distribution, making them an essential component in many modern electronic devices.

The conical shape of these inductors is not merely an aesthetic choice but a functional one that enhances their performance. The design allows for a gradual change in inductance along the length of the inductor, which helps in managing high-frequency signals effectively. This gradual change is key to reducing parasitic capacitance and enhancing the inductor's ability to handle a wide frequency range efficiently.

One of the interesting aspects of conical inductors is their winding structure. Unlike traditional inductors that have uniform winding, conical inductors often feature a tapered winding that results in an inductance that can be finely tuned. This feature is particularly useful in applications where precise control of inductance is required, such as in tunable RF circuits. Additionally, the construction of conical inductors typically involves materials that are optimized for magnetic performance, further enhancing their capabilities.

Conical inductors find their applications in several high-performance electronic systems. They are extensively used in RF (radio frequency) applications, where managing high-frequency signals is paramount. In telecommunications, these inductors help in filtering, impedance matching, and signal processing, enabling clear communication channels. Additionally, conical inductors are vital in automotive electronics, where they play a role in managing power supplies and reducing EMI, ensuring the reliable operation of critical vehicle systems.

Moreover, conical inductors are also used in power electronics, particularly in DC-DC converters and inverters. Their ability to handle high-frequency switching makes them ideal for applications that require efficient energy conversion. In audio equipment, they can enhance sound quality by delivering better signal integrity and reducing noise, making them valuable in high-fidelity audio systems. As technology continues to advance, the versatility of conical inductors will likely drive their adoption in emerging fields such as renewable energy and electric vehicles.

Compared to traditional cylindrical inductors, conical inductors offer several advantages. Their design leads to improved high-frequency performance and reduced electromagnetic interference. This makes them particularly useful in applications where signal clarity and integrity are essential. Furthermore, their compact size allows for integration into smaller, more efficient electronic devices, aligning with the industry's trend towards miniaturization.

In addition to their size and performance benefits, conical inductors can also be manufactured using various materials that enhance magnetic properties. For instance, ferrite cores can be used to improve inductance and reduce energy losses at high frequencies, making these inductors even more efficient. Moreover, the conical design can facilitate better thermal management, which is critical in high-power applications where excessive heat can degrade performance and reliability.

| Feature | Conical Inductor | Traditional Inductor |

|---|---|---|

| Design | Conical shape | Cylindrical shape |

| Frequency Handling | Wide range, high efficiency | Limited range |

| EMI Reduction | Highly effective | Moderate |

| Size | Compact | Bulky |

| Inductance Tuning | Precision tuning available | Limited tuning capability |

| Material Efficiency | Optimized materials for high-frequency | Standard materials |

Despite their advantages, conical inductors come with their own set of challenges. Manufacturing these components requires precision to maintain the integrity of their design, which can increase production costs. Additionally, their specialized nature means they may not be suitable for every application, particularly those not operating in high-frequency domains.

Another challenge is the limited availability of standardized conical inductors compared to traditional designs. This can make sourcing components more complicated for engineers and designers. Furthermore, the performance of conical inductors is heavily influenced by their construction quality and materials used. Variability in these factors can lead to inconsistencies in performance, necessitating stringent quality control measures during manufacturing.

Moreover, as the demand for high-frequency components grows, the market may become saturated with a range of inductors that promise different specifications and advantages. This can create confusion for designers who must choose the right component for their specific needs. Understanding the unique properties of conical inductors, along with the trade-offs involved, is essential for making informed design choices.

What makes conical inductors better for high-frequency applications?

Their design allows for better management of high-frequency signals by reducing parasitic capacitance and enhancing inductance variability, making them ideal for high-frequency applications. The tapered design minimizes the return path of the magnetic field, which is crucial in preventing signal degradation at elevated frequencies.

Are conical inductors suitable for all types of electronic devices?

While they are highly effective in specific applications like RF and telecommunications, they may not be necessary for all devices, particularly those not requiring high-frequency management. For instance, in low-frequency applications, traditional inductors may suffice, providing a cost-effective solution without the added complexity of conical designs.

How do conical inductors contribute to miniaturization in electronics?

Their compact size allows them to be integrated into smaller devices, aiding in the trend towards miniaturization without compromising performance. This is particularly important in consumer electronics, where space is often at a premium, and manufacturers are constantly seeking ways to reduce the footprint of their products.

Can conical inductors be used in power applications?

Yes, conical inductors are suitable for power applications, especially in switching power supplies and DC-DC converters. Their ability to handle high-frequency switching makes them effective in improving efficiency and performance in these systems.

What factors should be considered when selecting a conical inductor for a specific application?

When selecting a conical inductor, factors such as frequency range, inductance value, current rating, size, and material properties must be considered. Additionally, the specific requirements of the application, such as EMI reduction needs and space constraints, play a critical role in the selection process.

In conclusion, conical inductors represent a significant advancement in the field of electronics, offering superior performance in managing high-frequency signals and electromagnetic interference. As technology continues to evolve, the demand for these specialized components is likely to grow, underscoring their importance in the future of electronic design and manufacturing. The ongoing development of new materials and manufacturing techniques will further enhance the capabilities and applications of conical inductors, ensuring they remain a pivotal component in the ever-evolving landscape of electronics.

The future of conical inductors appears promising as the demand for high-frequency and miniaturized electronic devices continues to rise. As industries such as telecommunications, automotive, and consumer electronics evolve, the need for components that can efficiently manage electromagnetic interference and support high-speed data transfer becomes increasingly critical. Conical inductors, with their unique design and performance characteristics, are well-positioned to meet these challenges.

Research and development in this field are likely to focus on enhancing the materials used in conical inductors. Advances in nanotechnology and composite materials may lead to inductors that are not only more efficient but also capable of operating at higher temperatures and frequencies. Such developments could open new avenues for applications, particularly in fields like aerospace and medical devices, where reliability and performance are paramount.

Moreover, as the Internet of Things (IoT) continues to grow, the integration of conical inductors into more compact and efficient devices will be essential. The proliferation of smart devices requires components that can manage complex signals in a small footprint. Conical inductors can enhance the performance of these devices, enabling them to operate effectively in interconnected environments.

In summary, conical inductors are a vital component in the field of electronics, providing unique advantages in performance, size, and efficiency. Their specialized design not only improves high-frequency performance but also reduces electromagnetic interference, making them indispensable in modern electronic applications. As technology progresses and the need for high-performance, compact components increases, conical inductors will play an essential role in shaping the future of electronic design and manufacturing. The continual innovation in this area will ensure that conical inductors remain at the forefront of advancements in electronic systems, paving the way for new possibilities in a wide range of applications.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!