This article delves into the realm of conical inductors, essential components in modern electronic circuits. Conical inductors, characterized by their unique shape, offer distinct advantages in high-frequency applications. This piece explores their design, functionality, and the role they play in optimizing electronic performance.

In the ever-evolving field of electronics, conical inductors have emerged as pivotal components in various applications, particularly where high-frequency performance is crucial. Unlike traditional inductors, conical inductors feature a tapering design that enables superior performance characteristics, reducing parasitic effects and improving the quality of signal transmission. This unique configuration allows them to handle higher frequencies with greater efficiency, making them a preferred choice in many modern electronic designs.

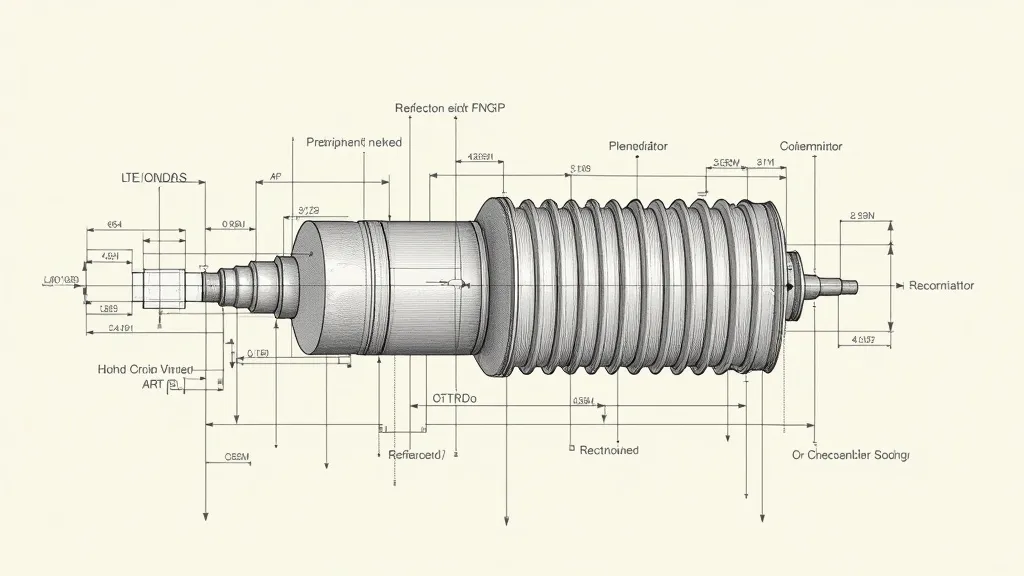

Conical inductors are named for their conical shape, which is not just an aesthetic choice but a functional one. This design minimizes the surface area and reduces the parasitic capacitance and inductance that plague traditional, cylindrical inductors. By having a wider base tapering to a narrower top, conical inductors provide a gradual impedance transformation, enhancing their efficiency in high-frequency environments. Additionally, the tapering shape allows for a more compact design without sacrificing performance, which is particularly important in space-constrained applications.

The construction of conical inductors typically involves winding wire around a conical form, which can be made from a variety of materials such as ferrite or air. The choice of core material significantly influences the inductor's performance characteristics, including its inductance value, quality factor (Q), and self-resonant frequency. For example, ferrite cores are often used in applications that require high inductance values and low losses, while air cores may be preferred for applications that demand higher frequencies and lower inductance.

Another important aspect of conical inductor design is the wire gauge used in the winding process. Thicker wires can reduce resistive losses but may increase the physical size of the inductor; therefore, designers must carefully balance wire size, material, and winding techniques to achieve the desired performance characteristics. The number of turns in the winding also plays a critical role in determining the inductance value, governed by the formula:

Inductance (L) = (N² * μ * A) / l

Where N is the number of turns, μ is the permeability of the core material, A is the cross-sectional area, and l is the length of the magnetic path. This equation underscores the importance of each design element in achieving optimal inductance and performance.

In modern electronics, conical inductors are indispensable in RF (radio frequency) applications, including telecommunications and broadcasting. They are used in devices such as smartphones, radios, and other wireless communication devices to filter signals and prevent interference, thus ensuring clear and reliable communication. Moreover, these inductors play a significant role in power management circuits, where they are utilized in DC-DC converters and switching power supplies to smooth out voltage levels and improve efficiency.

Conical inductors are also widely found in the automotive industry, particularly in electric and hybrid vehicles. They are used in power electronics for efficient energy conversion and management, which is critical for optimizing battery performance and extending vehicle range. Furthermore, in the realm of consumer electronics, conical inductors are employed in audio amplifiers and high-fidelity sound systems, where they help in maintaining signal integrity and delivering superior sound quality.

Beyond consumer electronics, conical inductors are essential in medical devices, including MRI machines and other imaging technologies. Their ability to handle high-frequency signals with minimal losses makes them ideal for applications where precision and reliability are paramount. By ensuring that the electromagnetic fields generated by these devices remain stable, conical inductors contribute to the accuracy and effectiveness of medical diagnostics and treatments.

| Inductor Type | Shape | Advantages |

|---|---|---|

| Conical Inductor | Conical | Reduces parasitic effects, better high-frequency performance, compact design |

| Cylindrical Inductor | Cylindrical | Simple design, cost-effective for low-frequency applications, easy to manufacture |

| Toroidal Inductor | Doughnut | Excellent efficiency, reduced electromagnetic interference, compact size |

| Planar Inductor | Flat | Low profile, ideal for surface-mount technology, good for high-density applications |

The choice of inductor type depends on several factors, including the specific application requirements, frequency range, and physical constraints. While conical inductors are favored for their high-frequency performance, other types may be chosen for their cost-effectiveness or ease of manufacturing. For instance, cylindrical inductors are often used in applications where low-frequency operation is sufficient, while toroidal inductors are preferred when minimizing electromagnetic interference is crucial.

The demand for conical inductors is on the rise, driven by the increasing need for high-frequency components in consumer electronics. Suppliers around the world are enhancing their production capabilities to meet this demand, offering a variety of conical inductors at competitive prices. Companies are also focusing on innovation, developing inductors that can operate efficiently at even higher frequencies. This trend is particularly evident in the telecommunications sector, where advancements in 5G technology have spurred the need for more sophisticated components that can handle greater data throughput.

Furthermore, the global push towards renewable energy and electric vehicles is also influencing the market for conical inductors. As industries shift towards more sustainable practices, the demand for efficient power management solutions is increasing, leading to heightened interest in inductors designed for high-frequency applications. Suppliers are responding by investing in research and development to create inductors with enhanced performance characteristics, such as improved thermal stability and increased power handling capabilities.

In addition to performance improvements, suppliers are also exploring various manufacturing techniques, such as automated winding and advanced core materials, to optimize production efficiency and reduce costs. The advent of new technologies, like additive manufacturing, is also paving the way for innovative designs that were previously not feasible. As a result, the market for conical inductors is expected to continue growing, with new entrants and established companies alike competing to capture a share of this expanding sector.

What is a conical inductor? A conical inductor is an electronic component with a cone-shaped design that minimizes parasitic effects, improving performance in high-frequency applications.

Where are conical inductors used? They are mainly used in RF applications, including telecommunications and broadcasting, to filter signals and prevent interference. Additionally, they are employed in power management circuits, automotive applications, and medical devices.

What are the benefits of using conical inductors? They provide better high-frequency performance and reduce parasitic capacitance and inductance compared to traditional inductors. Their compact design also allows for integration into space-constrained applications without sacrificing performance.

How do conical inductors compare to other types of inductors? Conical inductors offer superior high-frequency performance and reduced parasitic effects compared to cylindrical inductors, while toroidal inductors excel in minimizing electromagnetic interference. The best choice depends on specific application needs and constraints.

What advancements are being made in conical inductor technology? Innovations include the development of inductors that can operate at higher frequencies, improved thermal stability, and the use of advanced core materials and manufacturing techniques to enhance performance and reduce costs.

As technology advances, the importance of components like conical inductors becomes more pronounced. Their unique design and functionality make them indispensable in the realm of high-frequency electronics, ensuring efficient and reliable signal processing. As the market continues to grow, conical inductors will play a crucial role in the development of cutting-edge electronic devices. The ongoing demand for high-performance components in a variety of sectors, from telecommunications to automotive and medical technology, highlights the significance of conical inductors in shaping the future of electronics. With continuous improvements in design and manufacturing processes, the role of conical inductors is set to expand even further, paving the way for innovative applications and enhanced performance in the ever-evolving landscape of modern technology.

As we look to the future, it is clear that conical inductors will remain at the forefront of electronic component design, adapting to meet the challenges posed by new technologies and applications. Their ability to deliver superior performance in high-frequency environments will ensure their relevance and importance in the ever-competitive electronics market. By continuing to invest in research and development, manufacturers can unlock new possibilities for conical inductors, enabling them to support advancements in various fields such as telecommunications, automotive design, and healthcare solutions. Ultimately, the future of conical inductors is bright, and they will undoubtedly play a critical role in the ongoing evolution of electronic devices and systems.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!