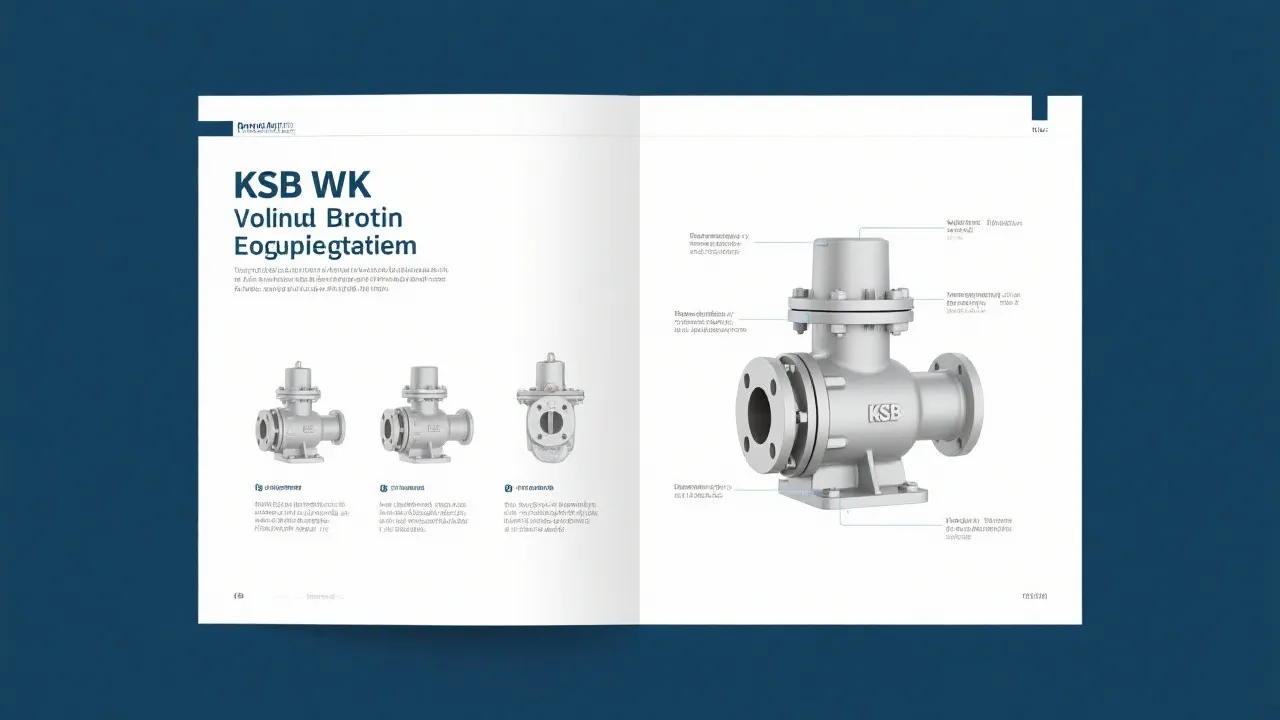

KSB WK represents a series of robust pumps designed for various industrial applications, known for their efficiency and reliability. This article delves into the features, applications, and benefits of the KSB WK pump range, offering a detailed comparison to other models. These pumps are typically utilized in sectors requiring heavy-duty performance, making them a critical asset in industries with demanding fluid handling needs.

The KSB WK series is synonymous with robust industrial pump technology. These pumps are revered in the fluid handling sector for their exceptional efficiency and adaptability across various applications. Whether it is in water treatment, energy, or industrial processes, KSB WK pumps deliver superior performance and reliability. Recognized for their high engineering standards, KSB WK pumps are suitable for both demanding operational environments and standard fluid transfer tasks. Their design integrates advanced materials and technology, ensuring they meet the rigorous demands of modern industry.

Water Treatment: Essential in municipal and industrial water treatment facilities, KSB WK pumps effectively manage large volumes of water, ensuring efficient delivery and processing. These pumps work efficiently in pumping water through filtration systems and handling backwashing tasks, ensuring consistent water quality for communities.

Energy Sector: Used in power plants and refineries, these pumps facilitate the movement of various fluids, including crude oil and natural gas, aiding in energy production and distribution. With certain KSB WK models capable of handling fluids at elevated temperatures and pressures, they are well-suited for critical applications in this sector.

General Industry: In manufacturing, food processing, and chemical industries, KSB WK pumps handle everything from basic water conveyance to the movement of complex chemical solutions. Their flexibility enables them to adapt to food grade certifications or hazardous chemical compliances, meeting industry-specific standards effectively.

Pulp and Paper Industry: KSB WK pumps are also employed in the pulp and paper industry where they handle slurries with varying consistencies and chemical compositions. Their robust build allows them to deal with abrasive materials, ensuring minimal wear and prolonging service life.

Agricultural Sector: In agriculture, KSB WK pumps support irrigation systems and water management, proving essential for crop management and livestock operations. These pumps enable farmers to transport water efficiently from reservoirs or direct sources to fields and ensure that crops receive adequate hydration, ultimately improving yield rates.

| Feature | KSB WK Pumps | Other Models |

|---|---|---|

| Efficiency | High, with optimized energy consumption | Varies with some models less efficient |

| Durability | Constructed from high-quality materials | Dependent on brand and model, often inferior |

| Versatility | Handles a wide range of industrial applications | Limited to specific functions or industries |

| Maintenance | User-friendly design for ease of maintenance | Can be complex and require specialist intervention |

| Customization | Options for varying sizes and materials | Limited customization based on manufacturer |

What makes KSB WK pumps preferable for industrial use? KSB WK pumps are highly efficient and durable, offering versatile applications across various industries. Their design features aim to cater to the needs of extensive fluid handling processes, enhancing productivity and supporting sustainability efforts due to reduced energy consumption.

How do KSB WK pumps contribute to energy savings? These pumps are designed to optimize energy usage by employing advanced hydraulic design to minimize resistance as fluid passes through the system. This leads to a significant reduction in power consumption during operation, making them a cost-effective choice for businesses striving to reduce energy costs.

Are KSB WK pumps easy to maintain? Yes, they are designed with user-friendly features that make maintenance and repair straightforward, minimizing downtime. Regular maintenance schedules can be performed without the need for specialized tools, which streamlines operations and helps maintain productivity in industrial settings.

Can KSB WK pumps handle corrosive fluids? Certain models of KSB WK pumps are specifically designed for corrosive environments and can handle acidic or alkaline fluids without compromising the integrity of the pump materials. The use of appropriate alloys and coatings prevents corrosion and extends the lifespan of the pumps under such conditions.

What is the typical lifespan of a KSB WK pump? The typical lifespan of a KSB WK pump depends on variables such as operating conditions, maintenance practices, and fluid characteristics. However, with proper care and regular maintenance, users can expect these pumps to serve effectively for many years, often exceeding several decades in service.

KSB WK pumps incorporate advanced technologies designed to improve performance, efficiency, and reliability. One such technology is the use of Computational Fluid Dynamics (CFD) during the design phase. This allows engineers to optimize the pump’s hydraulic components for better fluid flow while reducing energy losses. The integration of advanced simulation tools means that KSB WK pumps are tested under various conditions to ensure high performance across multiple scenarios.

Additionally, many models are equipped with smart technology that allows for enhanced monitoring and control. These pumps can be integrated into automated systems for real-time performance tracking and predictive maintenance. The IoT (Internet of Things) capabilities provide users with data analytics to optimize operations and preemptively address issues before they escalate into significant problems.

Furthermore, the pumping technology employed has evolved, with KSB focusing on minimizing noise pollution and vibrations which are essential for maintaining a conducive work environment. Improved motor drive systems are integrated into modern models, allowing for smoother operations and extending the overall life of the pumps while reducing energy consumption.

Selecting the appropriate KSB WK pump for a specific application can be a multifaceted process. Key considerations include the fluid types being handled, the required flow rates, discharge pressures, and the operational environment. Assessing these factors helps ensure that the pump selected operates within its design limits, promoting efficiency and reliability.

First, it’s crucial to understand the nature of the fluid, including its temperature, viscosity, and chemical composition. Some fluids may require pumps with specific material construction to avoid corrosion or wear, while others may necessitate pumps capable of handling slurries or particulates. Next, evaluate the flow rates and pressures required by your system. KSB provides detailed performance curves for their pumps that assist in identifying the best fit for your operational needs, displaying how different flow rates impact system pressures.

Another consideration is the installation environment. For instance, pumps located outdoors or in harsher conditions may require additional protection against environmental elements, which can be addressed by selecting models that come with appropriate enclosures or protective coatings. Furthermore, understanding your system’s maintenance capacity and scheduling will help in choosing pumps designed for easy access and serviceability, ultimately facilitating continuous operation without excessive downtime.

In the realm of industrial pumps, KSB WK stands out for its efficiency, durability, and broad applicability across numerous sectors. Equip your facilities with KSB WK pumps to ensure efficient fluid management, contributing to overall operational success. Their advanced technological integration, coupled with renowned reliability, makes them a trusted solution for both small-scale and large-scale industrial applications. As industries evolve, KSB WK pumps will continue to adapt and meet new challenges, empowering businesses to achieve greater efficiencies and sustainability in their operations.

The future of KSB WK pumps in the industrial landscape incorporates a strong emphasis on sustainability and environmental consciousness. As global industries increasingly pivot toward greener practices, KSB is committed to innovation that enhances efficiency while reducing carbon footprints. Future models may feature even more optimized energy consumption patterns through the integration of alternative energy sources, such as solar or wind power, especially for remote installations.

Moreover, advancements in materials science could lead to developments in pump construction, utilizing bio-degradable composites or new alloys that boast improved resistance to wear and corrosion, further extending the service life and reducing environmental impact. The anticipated rise of artificial intelligence in predictive maintenance also means that future KSB WK pumps will likely incorporate more sophisticated sensors and algorithms, analyzing data trends for maintenance needs and reducing unexpected failures.

In summary, as industries adapt to future demands, KSB WK pumps are poised to lead the charge in ensuring that fluid handling meets the evolving challenges and standards of efficiency, sustainability, and performance. Investing in KSB WK technology is not just a smart operational decision; it is an investment in the future of industrial processes.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!