Introduction to the DRV8704

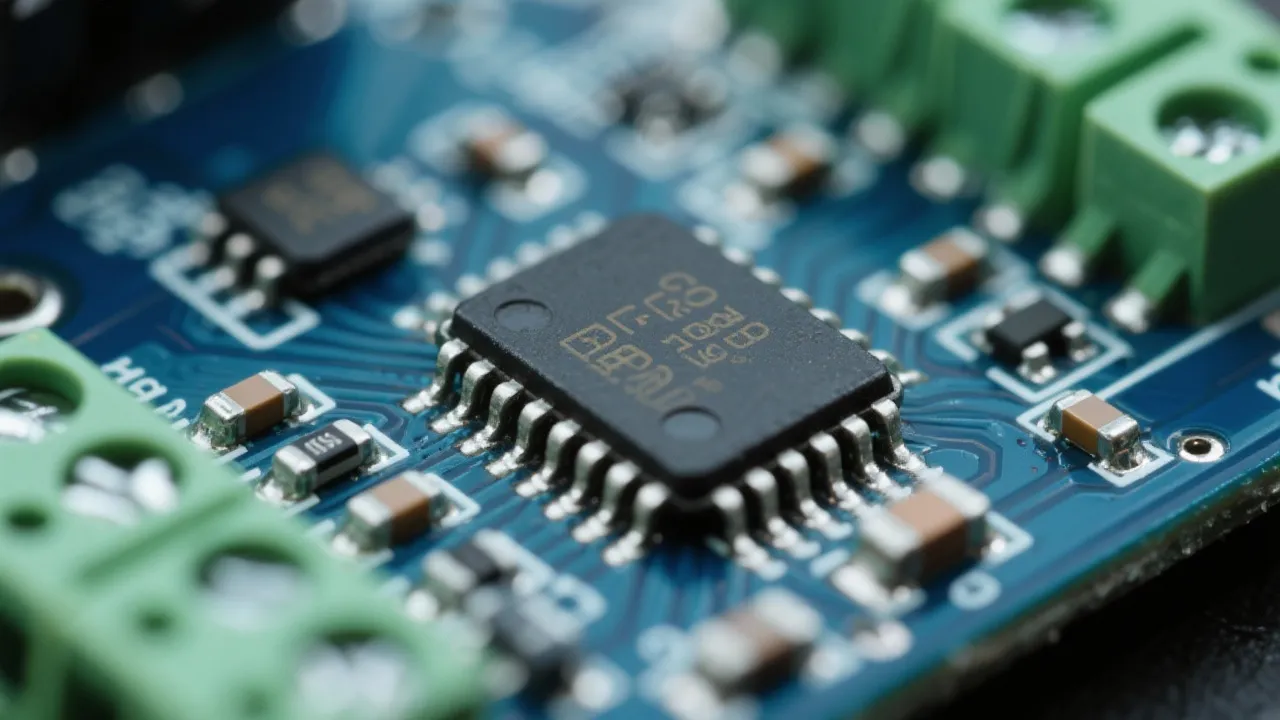

The DRV8704 is an advanced motor controller manufactured by Texas Instruments, designed to provide high-performance and reliable operation for various motor control applications. The versatility of the DRV8704 lies in its energy-efficient design and robust architecture, catering to a wide spectrum of industrial needs. This article delves deep into the intricacies of the DRV8704, making it an essential component for engineers working in sectors such as automation, robotics, automotive, and other related fields where precise control of motors is paramount.

Features and Technical Specifications

One of the standout features of the DRV8704 is its ability to control bipolar stepper motors. It incorporates a highly efficient PWM (Pulse Width Modulation) control which enhances motor performance significantly. The architecture of the DRV8704 supports multiple motor driving methods and can operate under different load conditions. More specifically:

- High Precision Control: The DRV8704 enables seamless management of motor phases, crucial for applications requiring high precision in rotation and position. Its advanced algorithms ensure that even minor adjustments can be executed with pinpoint accuracy.

- Efficiency: With its integrated current regulation and adjustable PWM frequency, the controller ensures optimal energy consumption. This feature not only contributes to lower operational costs but also enhances the overall system’s life span by reducing thermal output.

- Protection Mechanisms: Built-in overcurrent, overtemperature, and undervoltage protection safeguard connected motors. These safety features are essential for preventing damage during adverse operating conditions, ensuring longevity and consistent performance.

- Low Noise Operation: The DRV8704 is engineered for smoother operations, resulting in lower noise levels, which is particularly beneficial for applications in residential and healthcare settings where low noise is a requirement.

Applications in Industry

The DRV8704 is widely employed in numerous applications across various industries. Here’s a look at a few sectors where this motor controller proves invaluable:

- Automation: In automated production lines where precision and reliability are paramount, the DRV8704's precision control capabilities shine, allowing for synchronized operations of multiple motors and reducing production downtime.

- Robotics: Robotics systems leverage the controller's efficient energy management to sustain longer operational periods without overheating. This is critical in applications such as robotic arms, drones, and automated delivery systems where system weight and energy consumption are key performance metrics.

- Healthcare Devices: This motor controller finds its place in medical equipment where reliability and accuracy are critical for patient safety. For instance, devices like infusion pumps and surgical robots require precise motor control to ensure accurate delivery of medications and tools.

- Consumer Electronics: The DRV8704 is also applicable in consumer devices such as printers and cameras, where the smooth operation of motors contributes to enhanced user experience and product reliability.

- Automotive Applications: In the automotive industry, the DRV8704 is effectively used in various subsystems, including window regulators, seat adjusters, and steering systems, where precise control and safety are imperative.

Choosing the Right Motor Controller

When selecting a motor controller like the DRV8704, it is essential to consider several critical factors:

- Motor Compatibility: Ensure that the motor type aligns with the controller's specifications, particularly with regards to current ratings and voltage requirements. The DRV8704 is specifically designed for bipolar stepper motors; hence, it is crucial to pair it with suitable motor types to guarantee optimal performance.

- Desired Performance Outcomes: Consider what performance metrics are most important for your application. This may include speed, torque, or positional accuracy. Depending on these requirements, configure the parameters of the DRV8704 to achieve the best results.

- Specific Application Requirements: Different environments may have unique challenges. For example, applications in healthcare may necessitate higher reliability and safety features compared to consumer electronics. The adaptability and robust feature set of the DRV8704 make it a versatile choice for many applications.

- Support and Documentation: Take into account the availability of technical support and detailed documentation from manufacturers like Texas Instruments. The clarity of the user manual and reference designs can significantly expedite the development process.

- Cost-Effectiveness: Evaluate the cost against the features offered, ensuring that the long-term benefits in terms of performance and reliability justify the investment.

Installation and Setup Guide

Installing and setting up the DRV8704 involves several key steps to ensure correct functionality:

- Connect the Motors: Ensure all motor terminals are correctly attached to the controller's outputs. Utilizing appropriate connectors is vital to minimize resistance in the connections and improve overall performance.

- Power Supply: Verify that the power supply meets the voltage and current requirements outlined in the DRV8704 datasheet. It's advisable to use a regulated power supply to prevent voltage fluctuations that may affect performance.

- Configuration: Use the appropriate programming tools to configure the controller's settings via SPI communication for optimal performance. The DRV8704 allows for comprehensive configuration options that can be customized based on individual application needs. Ensure you have the necessary development software installed for this process.

- Testing: Conduct a series of operational tests to confirm that the DRV8704 is properly interfaced and managing motors as expected. This could include both functional tests and stress tests to evaluate performance under load.

- Troubleshooting: In case of unexpected behavior, consult the troubleshooting section of the user manual. Conduct thorough checks on wiring, power supply, and configuration settings.

| Feature |

Description |

| PWM Control |

Enhanced PWM control for efficient motor operation. This control technique minimizes power loss and heat, resulting in cooler operation and better efficiency. |

| Current Regulation |

Integrated current regulation for energy saving which adjusts the current through the motor to maintain optimal performance while avoiding excessive power consumption. |

| Protection Mechanisms |

Overcurrent, overtemperature, and undervoltage protection ensure safety during operation, helping to prevent hardware damage and promote system reliability. |

| Low Noise Operation |

Designed to minimize noise levels during operation, contributing to more comfortable user environments, especially in healthcare and consumer product applications. |

Case Studies

To understand the real-world application and benefits of the DRV8704, let’s look at a few detailed case studies:

Case Study 1: Automated Manufacturing Line

In an automated textile manufacturing facility, the DRV8704 was integrated into the control systems for stepper motors that drive fabric cutting machines. The requirement was for high precision and speed in cutting operations. The existing systems did not provide satisfactory speed control, resulting in fabric waste.

After implementing the DRV8704, the facility observed a dramatic decrease in fabric waste due to its precision control. The energy efficiency of the system improved as well, leading to reduced operational costs, highlighting the importance of choosing the right motor controller for improving manufacturing efficiency.

Case Study 2: Robotics in Warehousing

In a large warehouse setup, automated guided vehicles (AGVs) were used to transport goods efficiently. The initial setup utilized generic motor controllers that presented challenges in terms of power management and heat generation during prolonged usage. The movement accuracy was also insufficient, affecting delivery times.

By switching to the DRV8704 motor controller, the AGVs experienced improved energy efficiency, allowing for extended operation periods before needing recharging. Furthermore, the precise motor control enabled more accurate navigation through the warehouse, enhancing logistical efficiency and productivity.

Case Study 3: Precision Medical Devices

In the development of a state-of-the-art infusion pump for hospitals, the design team was challenged with maintaining high reliability and accuracy of drug delivery. They relied on a stepper motor for dosing precision but found that the previous motor driver could not provide the necessary control or safety features.

Upon integrating the DRV8704, the infusion pump not only met regulatory safety standards but also improved performance with a smoother dosage delivery mechanism. The built-in protection features reassured healthcare professionals regarding patient safety, significantly elevating the device's market competitiveness.

Future Prospects of Motor Control

As technology progresses, the demand for smarter and more efficient motor controllers continues to grow. In the coming years, advancements in motor control technology are expected to focus on various areas:

- Integration with IoT: The evolution of the Internet of Things (IoT) is set to usher in a new era of smart motor controllers. Integration will allow for remote monitoring and control, enabling predictive maintenance that increases system reliability and efficiency.

- Artificial Intelligence in Motor Control: Incorporating AI algorithms can lead to adaptive control systems. These systems can learn from operational data, improving their performance over time and responding dynamically to varying conditions and workloads.

- Enhanced Energy Efficiency: Future motor controllers like the DRV8704 will likely feature advanced energy harvesting techniques, recycling waste energy to minimize consumption. This aligns with global efforts toward sustainable manufacturing practices.

- Miniaturization: As devices become smaller and more compact, the need for miniaturized motor controllers that do not compromise performance is growing. This trend will drive innovation in semiconductor technology.

FAQs

- What types of motors can the DRV8704 control?

The DRV8704 is designed specifically for bipolar stepper motors, providing high-precision control and energy efficiency.

- What protections does the DRV8704 offer?

This motor controller includes thorough protective features such as overcurrent, overtemperature, and undervoltage protections, ensuring safe operation and longevity.

- Is the DRV8704 suitable for all industries?

While particularly useful in automation, robotics, and healthcare, its versatility makes it appropriate for any industry requiring precise and reliable motor control.

- Can the DRV8704 be used in battery-powered applications?

Yes, its efficient power management capabilities make it suitable for battery-powered devices, optimizing energy usage and extending battery life.

- What programming tools are needed for configuration?

The DRV8704 can be configured using standard SPI communication protocols, and a variety of development tools are available through Texas Instruments to assist in this process.

The DRV8704 motor controller stands out as a reliable choice for industries requiring efficient, high-performance motor management, positioning itself as a valuable component for today's technology-driven applications. Texas Instruments has created a product that not only meets but exceeds the expectations of engineers in various fields, paving the way for future developments in motor control technology.