The DRV8704 is a versatile motor driver chip utilized in numerous industrial and consumer applications. Known for its efficiency and high performance, it serves as a crucial component in motor control systems. This expert-led guide delves into the features, applications, and top practices for integrating the DRV8704, offering invaluable insights into its role within the broader field of electronics.

The DRV8704 motor driver is a critical component widely used in various motor control applications. Renowned for its high efficiency and functionality, the DRV8704 enables precise control of DC and stepper motors, making it indispensable in both industrial and consumer electronics. This driver integrates advanced technology to manage motors effectively, ensuring durability and high performance over extended periods. As motor applications are on the rise, understanding the role of the DRV8704 in these systems becomes increasingly important for engineers and hobbyists alike.

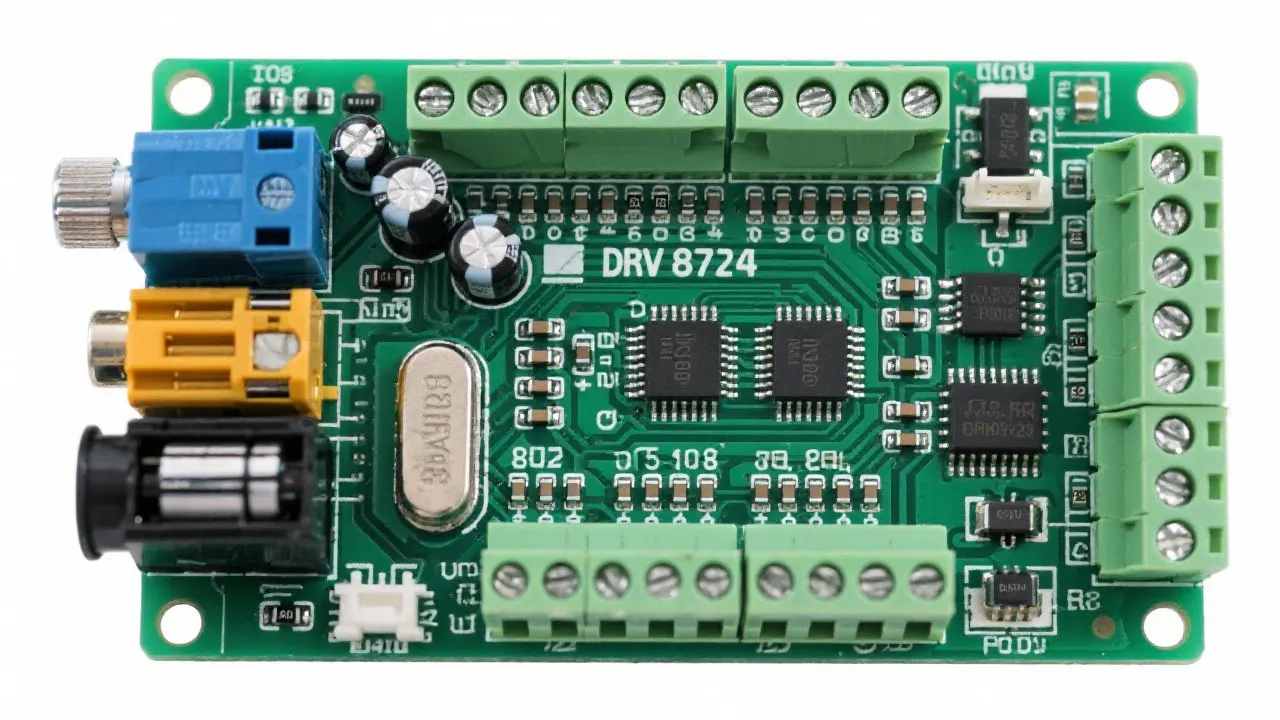

The versatility of the DRV8704 is mainly attributed to its key features, which include a current-limiting function to protect motors and advanced diagnostic capabilities. This chip supports dual H-bridge drivers, thereby facilitating efficient operation in a compact form factor. Its 6V to 52V operating voltage range ensures compatibility with diverse motor sizes and power requirements. Additionally, the DRV8704 is designed with a built-in charge pump, which enhances performance by allowing higher voltage levels, further elevating its efficiency in control applications.

| Feature | Description |

|---|---|

| Operating Voltage | Supports a wide voltage range from 6V to 52V, suitable for various motors. |

| H-Bridge Support | Features dual H-bridges for effective motor control. |

| Current Limiting | Integrated protection to prevent motor damage from excessive current. |

| Diagnostic Features | Comprehensive diagnostic tools to monitor performance and troubleshoot issues. |

| Built-in Charge Pump | Enhances performance by allowing higher voltage levels for the driver. |

The DRV8704 finds applications in a multitude of settings. From robotics to automated conveyor belts in manufacturing, it ensures efficient and precise motor control. In robotics, the accuracy provided by the DRV8704 allows for intricate movements and reliable operation of robotic arms, servos, and drive systems. Its adaptability also makes it a popular choice in consumer electronics, where reliability and performance are paramount. Devices such as printers, drones, and automated vacuum cleaners benefit from the driver’s efficient control mechanisms.

Moreover, the automotive industry increasingly utilizes the DRV8704 in electric motor systems, including window lifters and power steering applications. In industrial automation, this motor driver contributes to applications requiring high reliability and low maintenance, such as folding machines and packaging equipment. The flexibility and efficiency of the DRV8704 make it a vital component across various sectors.

For successful integration of the DRV8704, designers must consider the power requirements and desired control precision of their projects. Understanding the motor specifications and load characteristics is essential. It is crucial to analyze factors such as resistance, inductance, and rated current of the motors being used to guarantee they fall within the operational envelope of the DRV8704. Furthermore, careful planning in PCB design and selection of ancillary components can significantly enhance system reliability.

When implementing the DRV8704, it is advisable to include decoupling capacitors close to the device, which ensures stable voltage levels and reduces ripple. Furthermore, employing proper thermal management techniques, such as using heat sinks or thermal vias, enables prolonged operational life and prevents thermal shutdown during high load conditions. Each of these considerations plays a significant role in achieving optimal motor performance and system integrity.

To achieve optimal performance with the DRV8704, users should adhere to top practices such as implementing thermal management solutions and validating power configurations. Thermal performance can be monitored via built-in diagnostic features, allowing users to assess whether the operational temperature is within acceptable limits during usage. Understanding current ratings and motor load will further enable effective power distribution and component longevity.

Power supply considerations should also be factored in, including ripple voltage and how it may affect overall performance. The driver provides features that help mitigate issues such as back EMF that could lead to erroneous operation; thus, protective components like flyback diodes are crucial. Proper layout procedures, including reducing loop areas for high-frequency signals, can substantially improve performance as well.

Expert users can take advantage of the DRV8704’s advanced settings to tailor motor responses to specific applications. Adjusting the PWM frequency and using micro-stepping techniques can help in achieving smoother and more efficient motor operation. Micro-stepping, for instance, effectively divides a single step motor step into smaller increments, allowing for finer control of the motor and facilitating smoother motion, which is particularly important in applications requiring high precision, like 3D printers and CNC machines.

Additionally, careful tuning of operational parameters such as current limits and PWM dead time increases overall efficiency and prevents unwanted oscillations in motor operation, which can be detrimental to the system. Implementing feedback loops using encoder data can enhance performance even further by allowing real-time adjustments to motor control, thereby improving accuracy in applications where precise positional control is essential.

One exemplary application of the DRV8704 is in robotic systems, where precise motor control is fundamental for functionality. In a robotic arm designed for industrial use, the DRV8704 can control multiple DC motors driving joints and actuators. By utilizing the dual H-bridge capabilities, both forward and reverse movement can be executed with ease, allowing for sophisticated maneuvers. By adopting micro-stepping control, the arm can achieve a high degree of accuracy while maintaining a strong hold on objects, which is vital during operation.

Furthermore, integrating an encoder with the DRV8704 allows for precise position feedback, which can be utilized in control algorithms for more responsive motor operation. The system can monitor actual motor position against desired positions, adjusting inputs on-the-fly for a seamless operation, enhancing the robotic arm’s overall performance in tasks such as assembly, welding, or painting.

Q1: What types of motors can be used with the DRV8704?

A: The DRV8704 is compatible with both DC motors and stepper motors, offering flexibility in various applications.

Q2: How does the DRV8704 enhance system protection?

A: It features built-in current limiting and diagnostic functions to mitigate risks of overheating or current overdraw, safeguarding both the motor and driver.

Q3: Can the DRV8704 be used in low-voltage applications?

A: Yes, it operates efficiently in a wide voltage range, starting from as low as 6V.

Q4: What is the significance of the current-limiting feature in the DRV8704?

A: The current-limiting feature is crucial as it prevents excessive current flow that could lead to overheating and potential motor damage during stall conditions or heavy loads.

Q5: How does the DRV8704 perform in terms of power efficiency?

A: Thanks to its robust design and built-in charge pump, the DRV8704 maintains high power efficiency, which is essential for battery-operated devices or where thermal management is a concern.

Q6: Does the DRV8704 allow for thermal shutdown?

A: Yes, the DRV8704 includes a thermal shutdown functionality that automatically disables the driver when the temperature exceeds safe operating limits, providing an additional layer of protection for the device and the motor.

Lending itself to numerous uses, the DRV8704 motor driver is a benchmark for reliability and performance in electronic motor control systems. Its advanced features allow designers and engineers to develop innovative solutions that meet the rigorous demands of modern technology. By leveraging its robust features and adaptable nature, engineers and designers can craft innovative solutions that meet the demands of modern technology.

Ultimately, the integration of the DRV8704 in motor control systems not only enhances performance but also promotes energy efficiency and reliability. As industries continue to evolve, the applications for this driver will grow, paving the way for smarter, more efficient systems across various technological sectors. Grasping the full capabilities and potential of the DRV8704 will empower designers to push the boundaries of motor control technology even further, leading to advancements that could redefine automation and robotics industries.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!