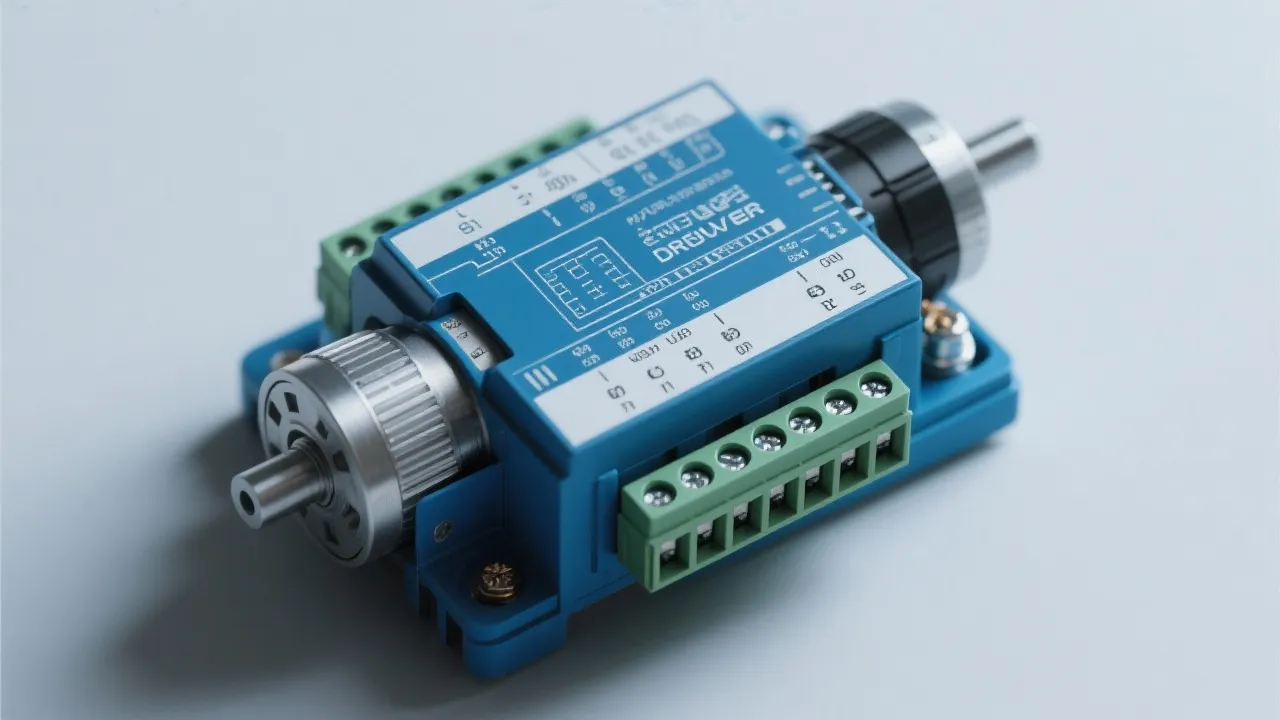

The DRV8704 is a robust device designed to drive a variety of motor types while balancing efficiency and control. In this guide, we delve into what makes the DRV8704 a standout option for designers and engineers. As a versatile component in the world of motor drivers, understanding its features, applications, and specifications is crucial for maximizing its potential in various projects.

As technology continues to evolve, the importance of efficient and reliable motor drivers like the DRV8704 becomes increasingly evident. The DRV8704, developed by Texas Instruments, is hailed for its versatility in driving brushed DC motors with precise efficiency. Whether in automotive applications, industrial equipment, or even home appliances, understanding the nuances of the DRV8704 is vital for engineers and designers aiming to harness its full potential. The device's capability of providing reliable and robust performance not only streamlines processes within various applications but also significantly enhances the overall user experience in terms of performance and efficiency.

The DRV8704 stands out due to its advanced specifications and features. It comes equipped with a configurable overcurrent protection mechanism, which helps in safeguarding the device against common issues faced in motor operations. The microstepping indexer integrated into the DRV8704 allows finer control over the motion of motors, making it an indispensable choice for high-precision applications. This allows engineers to not only ensure the longevity of the motors but also render them more efficient in operation, subsequently reducing wear and tear on mechanical components.

Engineers across various industries rely on the DRV8704 for its reliability and adaptability. In automotive systems, it provides the necessary torque and precision required for electric and hybrid vehicle components. The ability of the DRV8704 to handle high torque applications at various speeds makes it particularly valuable in automotive configurations, where performance directly impacts vehicle efficiency and safety.

In industrial settings, its robust design ensures durability and performance consistency, even under strenuous conditions. Applications in robotics, conveyor systems, and pumps often require a motor driver like the DRV8704 that can maintain efficiency during prolonged use with minimal downtime for maintenance. Furthermore, in home appliances, the DRV8704’s capacity for precise control translates to significant improvements in energy efficiency, which is paramount in today's environmentally-conscious market.

The versatility of the DRV8704 extends beyond these primary applications as it is also utilized in consumer electronics, such as drones and electric bicycles, each requiring precise control of motor speed and direction. The driver’s robustness ensures that it can meet the performance demands of various motor types, enhancing the overall functionality of innovative electronic solutions.

| Feature | DRV8704 | Competitor A | Competitor B |

|---|---|---|---|

| Voltage Range | 8-V to 52-V | 9-V to 40-V | 7-V to 45-V |

| Microstepping | Yes | No | Yes |

| Protections | Overcurrent, Overtemperature, Undervoltage | Overcurrent, Undervoltage | Overtemperature, Undervoltage |

| Operational Efficiency | High efficiency across a wide range of loads | Moderate efficiency with limited load range | High efficiency, but limited to specific applications |

The comprehensive features of the DRV8704, including its broad voltage range, microstepping capabilities, and multiple protection mechanisms, provide a significant advantage over competing products in the market. Many competitors lack the extensive protection features available, which places the DRV8704 in a tier above others, particularly in applications where safety and reliability are paramount consideriations.

Moreover, the operational efficiency of the DRV8704 allows for less power consumption and heat dissipation during operation, resulting in an overall improvement in system performance. Users can expect longer operational life and reduced frequency of maintenance, which is often a critical factor in industrial settings where downtime translates to lost revenue.

To maximize the functionality of your DRV8704, a thorough understanding of its installation and configuration process is essential. Setting up the device involves careful attention to circuit layout and parameter configuration to optimize performance.

In addition to these critical steps, engineers should conduct thorough testing of the installed system to identify and rectify potential issues early in the development process. Simulation tools are often available that can model the performance of the DRV8704 in conjunction with different motors, helping to troubleshoot before physical implementation. Utilizing thermal imaging cameras to monitor heat distribution while the driver operates will provide insights regarding cooling requirements and any necessary adjustments to the circuit layout.

The adaptability of the DRV8704 makes it suitable for diverse applications, from simple motor control tasks to complex systems where microstepping precision is requisite. As such, developers are encouraged to delve into advanced integration techniques that can further enhance performance and efficiency.

One innovative approach includes pairing the DRV8704 with microcontroller units (MCUs) or digital signal processors (DSPs) capable of dynamic feedback control. This method allows for real-time adjustments based on motor performance metrics, optimizing responsiveness and reducing unnecessary power consumption. Additionally, implementing feedback loops within control algorithms can enable the DRV8704 to automatically adjust its output based on changing load conditions.

Furthermore, integration with position sensors can enhance the functionality of the entire system. By leveraging encoders, for example, the system can achieve precise positioning and track motion more accurately. This is particularly evident in applications such as CNC machines and robotics, where precision is key to achieving desired outcomes.

The DRV8704 continues to be a benchmark for engineers and designers requiring a flexible and reliable motor driver. Whether you're working on automotive systems, developing industrial machinery, or even designing advanced consumer electronics, the DRV8704 offers the control and efficiency vital for precise motor management. Its broad feature set and adaptability ensure that it remains a top choice in modern engineering solutions.

The ongoing advancements in motor driver technology underscore the significance of adapting to evolving industry demands. As the fields of robotics, automotive technology, and intelligent systems continue to grow, a device like the DRV8704 presents unparalleled advantages. With its potent mix of advanced features and flexibility, it empowers engineers to push the boundaries of what's possible in motor control and drive design.

In summary, understanding the capabilities of the DRV8704 not only ensures optimal application performance but also fosters innovation across multiple sectors. As we move into a future that heavily relies on automation and precise machinery, tools like the DRV8704 will undoubtedly play a crucial role in shaping the landscape of electronic design and application productivity.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!