Introduction to the DRV8704

The DRV8704 stepper motor driver offers advanced control solutions for automotive and industrial applications. Built by Texas Instruments, this motor driver integrates effortlessly into any system requiring high power efficiency and precise motor control. Its robust design ensures reliable operation in challenging environments, making it an essential component for engineers and product designers. Moreover, the DRV8704 is designed not only to operate stepper motors but also to accommodate a variety of motor types, which adds to its versatility in practical applications.

Primary Features of the DRV8704

The DRV8704 is known for its rich feature set, including pulse-width modulation (PWM) control, current regulation, and fault detection capabilities. These features allow it to efficiently control the speed and torque of motors while protecting the system against issues like overcurrent, overvoltage, and overheating. Additionally, the driver features microstepping capabilities which enhance the smoothness of motor motion, thereby improving performance in precision applications.

- PWM Control: The DRV8704 supports adjustable PWM frequencies for adapting to different application needs, ensuring optimal performance across various motor types and systems. This is particularly beneficial for applications requiring variable speeds and adjustments, allowing engineers to fine-tune motor performance according to specific operational conditions.

- Current Regulation: This feature minimizes power consumption by maintaining constant current levels, enhancing motor performance by ensuring smooth and stable operation. The ability to regulate current not only aids in controlling motor speeds but also prevents damage that may arise from excessive current draw, making it essential for longevity and reliability.

- Fault Detection: With built-in diagnostics, the DRV8704 can quickly detect and respond to faults, preserving the system's longevity and reliability. Its ability to report fault conditions through the SPI interface allows for easy integration into more complex systems where diagnostic information can assist in preventive maintenance.

- Microstepping: The microstepping feature allows for finer control of motor movement. By providing a greater number of steps per revolution, microstepping minimizes the steps of motor action, significantly reducing torque ripple and enhancing precision in applications that require careful positioning.

Applications of the DRV8704

The DRV8704 is adaptable and is commonly used in environments that demand precise motor operation. Key applications include:

- Robotics: Ideal for driving motors in robots, where precise motion control is paramount. Robotics applications can vary vastly, from robotic arms in manufacturing to autonomous mobile robots that navigate complex environments.

- Automotive Systems: Used for electronic throttle control, HVAC systems, and other vehicular applications. The DRV8704's features translate into improved vehicle responsiveness and efficiency, potentially contributing to better fuel economy and reduced emissions.

- Industrial Equipment: Supports conveyor belts, fans, pumps, and other machinery requiring reliable motor management. The robustness of the DRV8704 makes it particularly suitable for harsh industrial environments where dust, temperature fluctuations, and mechanical vibrations can be prevalent.

- 3D Printing: Many 3D printers utilize stepper motors for precise movement along multiple axes. The DRV8704 can effectively control these movements, ensuring high fidelity and accuracy in printed objects.

- Medical Devices: In medical devices where precision is critical, such as in imaging equipment or robotic surgical tools, the DRV8704's reliable performance ensures that these devices can operate within their required parameters without failure.

- Home Automation: As smart homes become more prevalent, devices such as automated curtains, blinds, and adjustable shelving can benefit from the DRV8704's precise control capabilities, allowing seamless integration into home automation systems.

Technical Specifications

| Specification |

Details |

| Supply Voltage |

Up to 52V, allowing for versatility in different applications. |

| Output Current |

Can drive motors needing up to 4.5A RMS current, providing substantial power for a wide range of motors. |

| Interface |

SPI for control and diagnostics, enabling easy integration into microcontroller-based systems. |

| Package |

HTSSOP with PowerPAD for efficient thermal management, ensuring that heat dissipation is handled effectively to protect the integrity of the device. |

| Microstepping Resolution |

Up to 1/256 microstepping, delivering impressive smoothness in movement. |

| Operating Temperature Range |

-40°C to +125°C, making it suitable for a wide range of environmental conditions. |

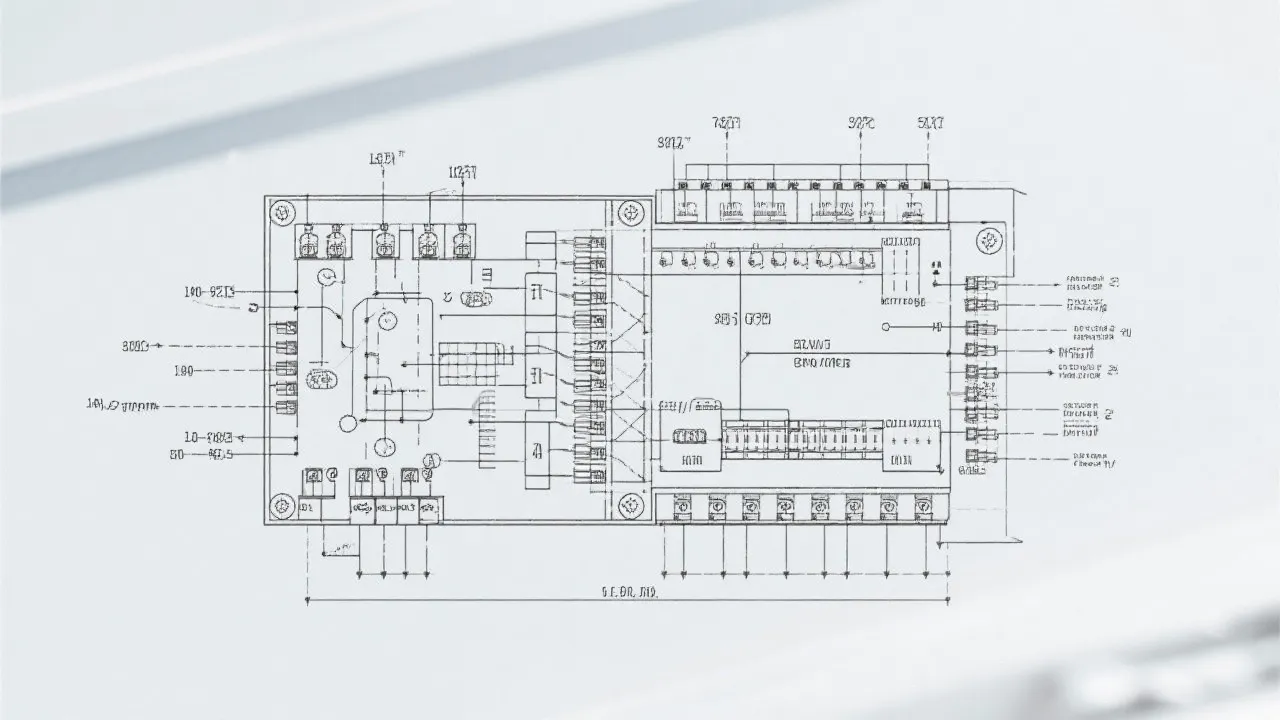

Integrating the DRV8704 into Your System

When integrating the DRV8704 into a new or existing system, engineers must carefully consider the operating environment to maximize efficiency and reliability. The choice of accompanying components, such as heat sinks and capacitors, plays a crucial role in the overall performance. Specifically, ensuring adequate thermal management not only promotes reliability but can also enhance performance by preventing thermal throttling, particularly in high-load situations.

Moreover, attention must be given to the PCB layout when integrating the DRV8704. Proper placement and routing of power and ground traces can minimize voltage drop and inductive coupling, both of which can affect performance and noise levels. Ensuring that power connections are robust and that decoupling capacitors are placed as close to the power pins as possible will help maintain consistent voltage levels during operation.

Furthermore, designers should familiarize themselves with the DRV8704's configuration options available through the SPI interface. Configuring parameters such as current limits and PWM frequencies through software provides an added layer of flexibility, allowing the driver to be easily adapted to various applications and operational requirements. Adequate testing under various load conditions should also be undertaken to ensure that the system is optimized for its intended use. This can include thermal testing, noise characterization, and dynamic response analysis.

FAQs

- What motors are compatible with the DRV8704?

The DRV8704 is compatible with a variety of motors, particularly stepper motors and brushed DC motors, due to its sophisticated control capabilities. Some users have successfully driven brushless DC motors with additional circuitry, showcasing the versatility of the driver.

- How can I troubleshoot fault conditions?

Utilize the SPI interface to monitor and diagnose faults, which the DRV8704 will report automatically, helping to quickly address and rectify underlying issues. Regularly checking the fault flags can preemptively alert designers to potential issues before they lead to system failures.

- What are key tips for ensuring thermal management?

Ensure that your design incorporates adequate heat dissipation methods, such as using additional cooling mechanisms and optimal PCB layout to prevent overheating and ensure stable operation. Incorporating thermal vias and using a thermal pad design on the PCB can significantly help manage heat build-up.

- Can I use the DRV8704 for high-speed applications?

Yes, the DRV8704 is capable of handling high speeds, particularly with stepper motors. The adjustable PWM frequency allows for the performance tuning necessary to swing the stepper motor through operation efficiently, although each application will need to be assessed individually for optimal settings.

- Is there a development kit available for the DRV8704?

Yes, Texas Instruments offers evaluation modules that allow engineers to test and prototype designs using the DRV8704. These kits often come with necessary documentation and software to facilitate rapid development and testing.

Advanced Features of the DRV8704

Beyond its primary features, the DRV8704 boasts several advanced capabilities that further enhance its appeal to engineers across various industries:

- Adjustable Decay Mode: The driver allows selection between fast decay and slow decay modes to control motor torque and performance. Fast decay is used for applications requiring rapid direction changes, while slow decay can help in applications needing smoother motion.

- Adaptive Current Control: The DRV8704 can dynamically adjust the current applied to the motor based on load conditions, ensuring improved efficiency and reduced heat generation across various operating states.

- Synchronous Rectification: This feature enhances efficiency by minimizing power loss during operation, which is especially beneficial in battery-powered applications. Synchronous rectification also helps maintain continuous torque and current control.

- Error Reporting: The driver can provide detailed error codes that describe the nature of the fault, whether it's a thermal issue, overcurrent trigger, or other anomalies. This plays a significant role in debugging and enhances the maintainability of systems utilizing the driver.

Comparison with Other Drivers

When evaluating the DRV8704 for potential integration, it is also helpful to compare it with other motor driver ICs available in the market. Competing products from other manufacturers may offer similar specifications; however, the DRV8704's unique features provide distinctive advantages:

- Efficiency: The DRV8704's adaptive current control and PWM capabilities allow it to outperform many competitor devices by delivering more precise control while also conserving power, thus extending battery life in portable applications.

- Microstepping Capability: While many drivers offer basic stepping capabilities, the DRV8704's ability to operate at up to 1/256 steps allows for exceptionally smooth motion, beneficial for precision control applications.

- Fault Monitoring and Reporting: The extensive fault detection features, including the capability of providing real-time diagnostics, set the DRV8704 apart as a sound choice for high-reliability applications where downtime is costly.

- Robustness: Designed for operating in extreme environments with wider temperature ranges and supply voltages, the DRV8704 can be a better fit in demanding applications, reducing the risk of component failure.

Future Trends in Motor Control Technology

The field of motor control technology is continually evolving, driven by advancements in both hardware and software. As industries demand more efficient and sophisticated motor control systems, several trends are emerging:

- Higher Integration: Future motor drivers may begin to integrate additional functionality directly onto the chips, including onboard sensors for real-time feedback, thus further enhancing control accuracy without the need for extensive external components.

- Smart Motors: The concept of smart motors is gaining traction, where motors will not only respond to control signals but also adapt their behavior based on real-time operational data. You might see integration with AI and machine learning algorithms to optimize motor performance based on usage patterns.

- Increased Communication Interfaces: The expansion of IoT applications could lead to drivers featuring enhanced communication protocols. This would enable motor control systems to communicate effectively within smarter networked systems, allowing remote diagnostics and automated updates or adjustments.

- Energy Harvesting: In the push for sustainability, the development of energy-harvesting technologies paired with efficient motor drivers may allow devices to harness energy from their environments, improving autonomy in applications such as sensors or remote-controlled devices.

Conclusion

In conclusion, the DRV8704 emerges as a versatile and efficient solution for motor driver applications. Whether in robotics, automotive, or industrial machinery, its comprehensive features and robust specifications cater to the demanding requirements of precise motor control systems. With advantages such as microstepping capabilities, extensive fault monitoring, and a wide range of compatibility, it is an excellent choice for engineers seeking to implement a reliable and cost-effective motor driver. As industries continue to evolve and the demand for efficient motor control grows, the DRV8704 stands ready to meet these challenges, representing a significant advancement in technology.