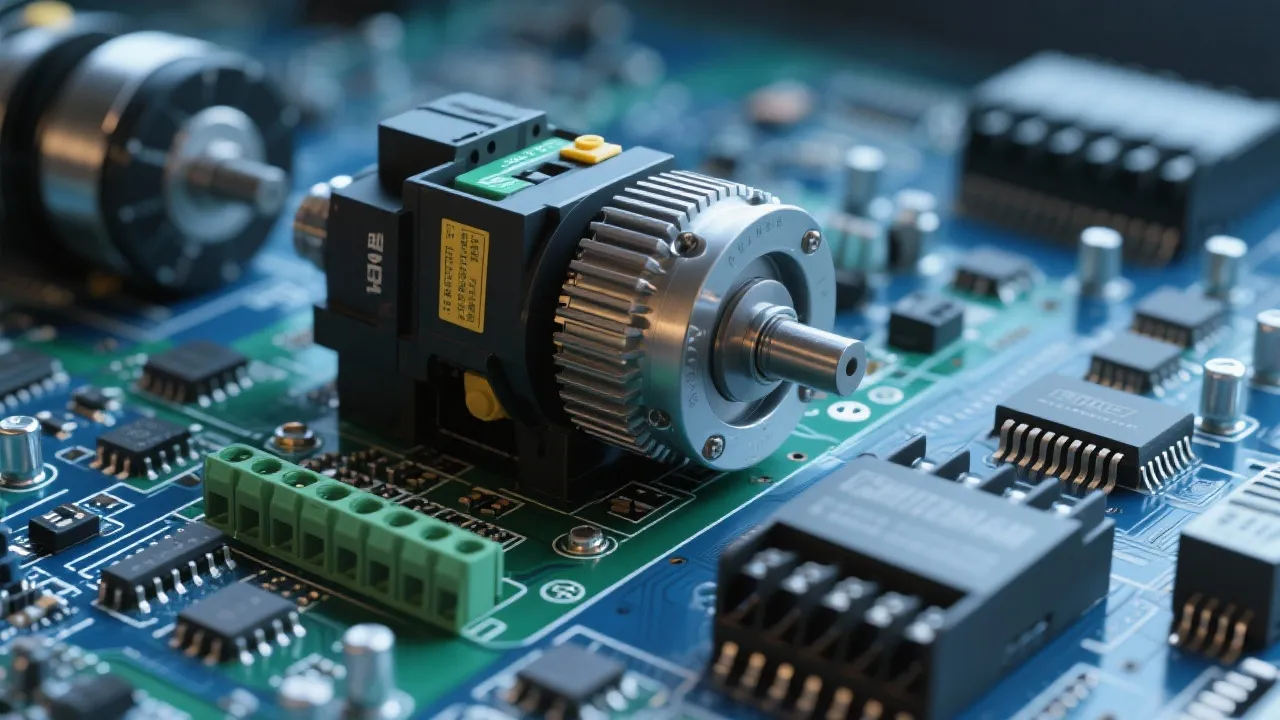

Motor drivers, such as the DRV8704, are crucial components in controlling the power and direction of motors. Used extensively in various electronic applications, this guide delves into the specifications and functionalities of the DRV8704, offering insights and guidance on its implementation for enhanced performance in electric motor systems.

Motor drivers are pivotal components in today’s electronic systems that leverage electric motors. These drivers not only facilitate the control of motors but also serve as an interface between microcontrollers and the motors themselves. The evolution of motor drivers over the years has led to the creation of more sophisticated and efficient options, one of which is the DRV8704, manufactured by Texas Instruments. The DRV8704 is celebrated for its versatile functionality, high reliability, and integrative design features that allow for increased control over the performance of DC motors.

With the growing demand for precision control in various applications, including robotics, automotive, and industrial automation, the DRV8704 meets the need for an adaptable solution that caters to different DC motor specifications. This sophistication ensures it can handle not just a single application, but a myriad of operational scenarios, from simple consumer electronics, like toys and appliances, to complex industrial machinery, indicating its wide-ranging applicability and importance in electrical engineering.

The technical specifications of the DRV8704 set it apart from other motor drivers in its category. It is designed as a robust H-bridge driver capable of driving two DC motors simultaneously, making it particularly useful for projects requiring multiple motor operations. The dual full-bridge configuration ensures that the motors can operate independently or be synchronized, depending on the application needs.

The operating voltage of the DRV8704 ranges from 6.5V to 45V, making it suitable for a diverse array of motor sizes, power requirements, and application types. This expansive range allows engineers to use the DRV8704 in low-voltage applications as well as in high-voltage industrial environments. Moreover, the integration of essential protection features, including under-voltage lockout, thermal shutdown, and overcurrent protection, ensures that the driver maintains reliable performance even under challenging conditions, thereby minimizing the risk of damage to the driver and connected motors.

In addition to the basic motor control features, the DRV8704 incorporates functionalities like adjustable current limits and the ability to monitor motor currents, providing crucial data for feedback control systems. This functionality is essential in applications demanding precise motor movements, enabling adjustment and fine-tuning of motor control strategy for enhanced efficiency.

Several fundamental features make the DRV8704 a preferred choice among engineers and developers seeking efficient motor driver solutions:

For engineers and developers aiming to leverage the capabilities of the DRV8704 in their projects, a clear understanding of its setup and operation is crucial. The integration process, while relatively straightforward, requires a fundamental knowledge of electrical circuit design and an understanding of motor dynamics. Here’s a step-by-step guide for implementing the DRV8704 in a standard project:

When selecting a motor driver, engineers often compare options to ensure the best fit for their specific applications. Below is a comparative analysis highlighting the DRV8704 in relation to other popular motor drivers, specifically the DRV8833 and the DRV8870:

| Feature | DRV8704 | DRV8833 | DRV8870 |

|---|---|---|---|

| Voltage Range | 6.5V to 45V | 2.7V to 10.8V | 6.5V to 45V |

| Max Output Current | 6.5A Peak | 1.5A Peak | 3.6A Continuous |

| PWM Control | Yes | Yes | No |

| Applications | Industrial, Robotics | Battery-powered, Small Appliances | Automotive, Consumer Electronics |

The comparison table illustrates several key distinctions between these motor drivers. Notably, the DRV8704 offers the highest voltage and current ratings, making it suitable for demanding applications such as industrial automation and robotics where performance under load is critical. In contrast, the DRV8833, with its lower voltage limits and current capacity, is tailored for battery-powered devices and smaller appliances where the operational requirements do not exceed these specifications. The DRV8870 serves as a middle-ground alternative, suitable for automotive applications with a significant current handling capacity but lacks the extensive PWM control features seen in the DRV8704.

The versatility of the DRV8704 allows it to find applications across various industries. Below are some case studies demonstrating its efficacy in real-world scenarios:

In robotics, precision and reliability are paramount. A robotics company implemented the DRV8704 in their latest autonomous robot for controlling the drive motors. The project required a dual-motor setup, where each motor needed to be controlled independently to facilitate complex maneuvers. The DRV8704’s dual full-bridge configuration allowed seamless synchronous control, enabling the robot to navigate through obstacles accurately. Moreover, the ability to monitor and sense motor currents enabled the development team to implement effective feedback loops, significantly improving the robot's performance in dynamic environments.

In an industrial setting, a manufacturer required robust motor control systems to operate conveyor belts and other machinery. The DRV8704 was chosen due to its high voltage and current capabilities, making it a perfect match for heavy-duty applications. The integrated thermal and overcurrent protections helped increase the reliability of the system, significantly reducing downtime due to motor damages. Additionally, the current sensing feature allowed the engineers to monitor the power consumption in real-time, facilitating predictive maintenance and optimizing energy usage.

In the automotive industry, electric vehicles (EVs) require efficient and reliable motor drivers to manage propulsion systems. Implementing the DRV8704 in an EV prototype allowed the engineering team to explore various control strategies for driving multiple motors while maintaining a compact design. The high peak current capacity addressed the dynamic demands during acceleration while ensuring that the motors operated within safe limits. Furthermore, the PWM control functionalities enabled precise speed and torque control, enhancing the overall driving experience and efficiency of the vehicle.

The DRV8704’s high voltage and current handling capabilities make it ideal for industrial applications where robust motor control is essential. Its protective features further safeguard machinery and prevent downtime due to failures.

While it is feasible to utilize the DRV8704 in battery-powered devices, its higher voltage requirements may not align with lower voltage battery configurations. Devices that utilize higher voltage outputs could effectively leverage this driver.

This configuration allows for versatile motor control, enabling the driver to handle two motors independently or in synchronization. This flexibility is advantageous for applications requiring complex movements and coordinated operations.

The maximum operating temperature for the DRV8704 is typically around 150°C. However, it is essential to design the surrounding electronics with adequate thermal management to prevent the driver from reaching this temperature during operation.

The DRV8704 employs efficient PWM control that adjusts the power delivered to motors dynamically, reducing energy waste during operation. Coupled with its current sensing ability, this gives engineers the tools needed to optimize motor performance while conserving energy.

The DRV8704 emerges as a standout option among motor drivers due to its flexibility, comprehensive protective features, and ability to manage high power requirements efficiently. Its design accommodates both simplified consumer applications and complex industrial environments, illustrating its adaptability. A thorough understanding of its specifications and implementation techniques maximizes the advantages it offers across a range of motor-driven systems. As technology progresses, components like the DRV8704 will continue to play a crucial role in enhancing motor control capabilities in ever-evolving applications, setting the stage for future innovations and advancements in motor driver technology.

Moreover, as engineers continue to explore new applications and optimize existing designs, the insights provided from real-world implementations of the DRV8704 can serve as valuable references. Continuous advancements in motor driver technology promise to enable even greater efficiency and control, paving the way for the next generation of robotics, electric vehicles, and automated systems.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!