Parker pneumatic actuators play a crucial role in various industrial applications, providing efficient and reliable motion control. These devices convert compressed air energy into mechanical motion, which is vital in automation systems. As one of the leaders in motion and control technologies, Parker offers a range of actuators designed to meet diverse industry needs, ensuring optimal performance and durability.

Pneumatic actuators are essential components in modern industrial systems, instrumental in automating processes by converting compressed air energy into mechanical motion. Parker, a leader in motion and control technologies, has established itself as a trusted provider of pneumatic actuators. These devices are characterized by their reliability, efficiency, and adaptability, making them an ideal choice for various applications. The use of pneumatic actuators is increasingly common in sectors where precise motion control is critical, and Parker's products are among the most respected in the industry.

Parker pneumatic actuators are used across multiple industries, including manufacturing, automotive, and aerospace. Their primary function is to control the movement of equipment, enhancing productivity and safety. These actuators are designed to handle extreme conditions, ensuring consistent performance even in harsh environments. With the rise of automation in industrial processes, the demand for reliable actuators has surged, making Parker's pneumatic solutions vital for modern operations.

In manufacturing, for example, pneumatic actuators facilitate the automation of assembly lines, reducing the need for manual intervention and minimizing errors. They provide the necessary force to move components efficiently and accurately, which can significantly enhance production rates. In the automotive industry, they are used in robotic arms for precise control of assembly and painting processes, allowing for consistent quality and reduced labor costs. Meanwhile, in aerospace, these actuators contribute to the control systems of aircraft, ensuring smooth operation and safety. Their role in these critical applications cannot be overstated, as they often serve as the backbone of operational efficiency.

Parker pneumatic actuators are renowned for their robust construction and advanced features, which include:

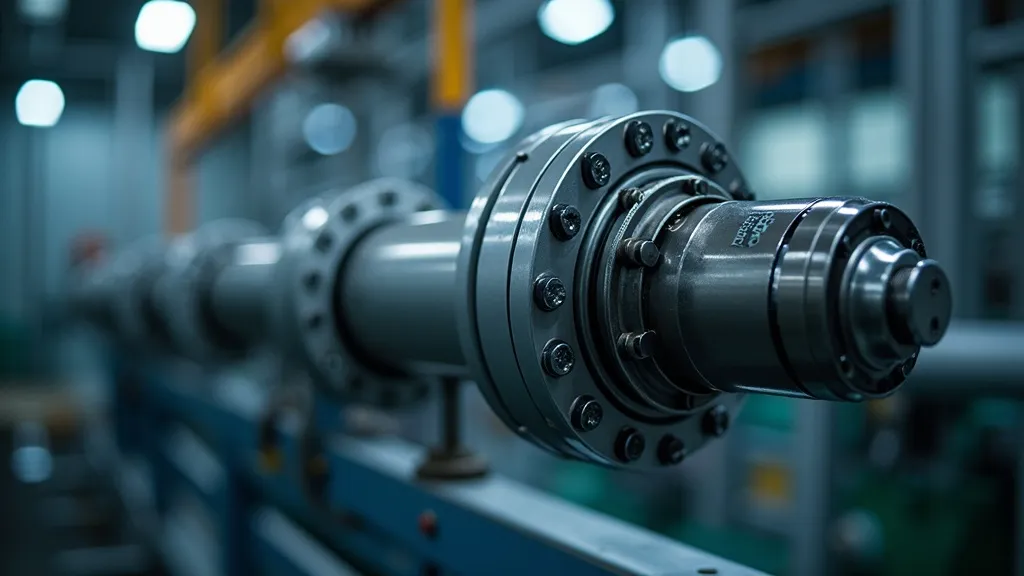

At the heart of every pneumatic actuator is a mechanism that translates air pressure into mechanical motion. The basic principle involves the use of compressed air that enters a cylinder, pushing a piston within the cylinder. This piston, in turn, creates linear motion, which can be harnessed to do work, such as moving a valve or actuating a mechanical arm.

The design of Parker pneumatic actuators often includes features such as adjustable stroke lengths, allowing for flexibility in movement. Some models may incorporate sensors that monitor the position of the actuator, providing feedback to control systems that can optimize performance further. The ability to finely tune the actuator's stroke length and response time makes Parker actuators particularly useful in applications requiring high precision.

| Model | Features | Applications |

|---|---|---|

| Series A | Compact design, high efficiency | Manufacturing, automation |

| Series B | Heavy-duty, robust construction | Aerospace, automotive |

| Series C | Customizable, precision control | General industry, robotics |

Each series of Parker pneumatic actuators is tailored to meet specific operational demands, ensuring that users can select the best option for their application. For instance, Series A's compact design is ideal for tight spaces, while Series B's heavy-duty construction is perfect for applications that require resilience against high stress and harsh conditions. The flexibility offered by Series C allows for precise control, making it suitable for advanced robotic systems and intricate manufacturing setups.

According to industry experts, Parker pneumatic actuators stand out due to their seamless integration into existing systems and their ability to enhance operational efficiency. The adaptability of these actuators allows them to meet the evolving demands of industries, making them a preferred choice for engineers and technicians alike. Their design philosophy emphasizes not only performance but also the ease of installation and maintenance.

Furthermore, Parker's commitment to innovation ensures that their pneumatic actuators are at the forefront of technology. By continuously improving their designs, Parker ensures that their products meet the highest standards of quality and performance. Innovations in materials science, such as the use of lightweight composites and advanced seals, have contributed to the enhanced performance of their actuators. These advancements not only increase the lifespan of the actuators but also improve their energy efficiency, making them more environmentally friendly.

To ensure the longevity and optimal performance of Parker pneumatic actuators, regular maintenance is essential. Here are some best practices for maintaining these devices:

Q: What industries primarily use Parker pneumatic actuators?

A: Parker pneumatic actuators are widely used in manufacturing, automotive, aerospace, and general industrial applications. Their versatility makes them suitable for any sector that requires motion control.

Q: What makes Parker pneumatic actuators reliable?

A: Their high-quality construction, efficient design, and adaptability to various conditions contribute to their reliability. Parker's rigorous testing and quality assurance processes also ensure that their actuators meet high-performance standards.

Q: Can Parker pneumatic actuators be customized?

A: Yes, Parker offers a range of configurations and customizations to meet specific application needs. This customization can include variations in size, stroke length, and additional features tailored to fit particular requirements.

Q: Why are pneumatic actuators preferred over other types?

A: Pneumatic actuators offer advantages such as quick response, ease of maintenance, and cost-effectiveness, making them a popular choice in many industries. They are also less prone to overheating compared to electric actuators, making them suitable for continuous operation in demanding environments.

Parker pneumatic actuators provide a robust solution for industries seeking reliable and efficient motion control. By offering a range of models and customization options, Parker ensures that their actuators can meet the diverse demands of modern industrial applications. Their emphasis on quality and innovation guarantees that Parker remains a leading provider in the field of pneumatic technology.

As industries evolve, so does the technology behind pneumatic actuation. Future trends in this field are likely to be influenced by advancements in automation, artificial intelligence, and the growing emphasis on sustainability. For instance, the integration of smart sensors and IoT (Internet of Things) technology into pneumatic systems will enable real-time monitoring and control, enhancing efficiency and reducing downtime.

Moreover, as industries push for more sustainable practices, the development of energy-efficient pneumatic actuators will become increasingly important. Companies like Parker are already exploring new materials and designs that reduce air consumption and improve overall energy efficiency. This focus on sustainability is not just about reducing costs; it also aligns with global efforts to minimize environmental impact.

Another area of innovation is the development of hybrid systems that combine pneumatic and electric actuation. This approach can harness the advantages of both technologies, providing flexibility and efficiency in various applications. For example, a hybrid system might use pneumatic actuators for high-speed operations while employing electric actuators for tasks requiring precise control. This combination can lead to improved performance and adaptability in complex industrial environments.

Parker has consistently demonstrated a strong commitment to research and development, which is crucial for staying ahead in the competitive field of pneumatic technology. By investing in R&D, Parker aims to create innovative solutions that address the evolving needs of its customers. This includes exploring new materials, enhancing actuator designs, and incorporating advanced technologies that improve functionality and reliability.

The company collaborates with universities and research institutions to leverage the latest scientific advancements. These partnerships not only facilitate innovation but also help Parker to anticipate industry trends and customer needs. This proactive approach ensures that Parker's pneumatic actuators are not only current with today's technologies but are also prepared for the challenges of tomorrow.

Parker pneumatic actuators provide a robust solution for industries seeking reliable and efficient motion control. By offering a range of models and customization options, Parker ensures that their actuators can meet the diverse demands of modern industrial applications. Their emphasis on quality, innovation, and sustainability positions Parker as a leader in pneumatic technology. As the industry evolves, Parker's commitment to excellence will continue to drive advancements in the field, ensuring that they remain at the forefront of motion and control solutions.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!