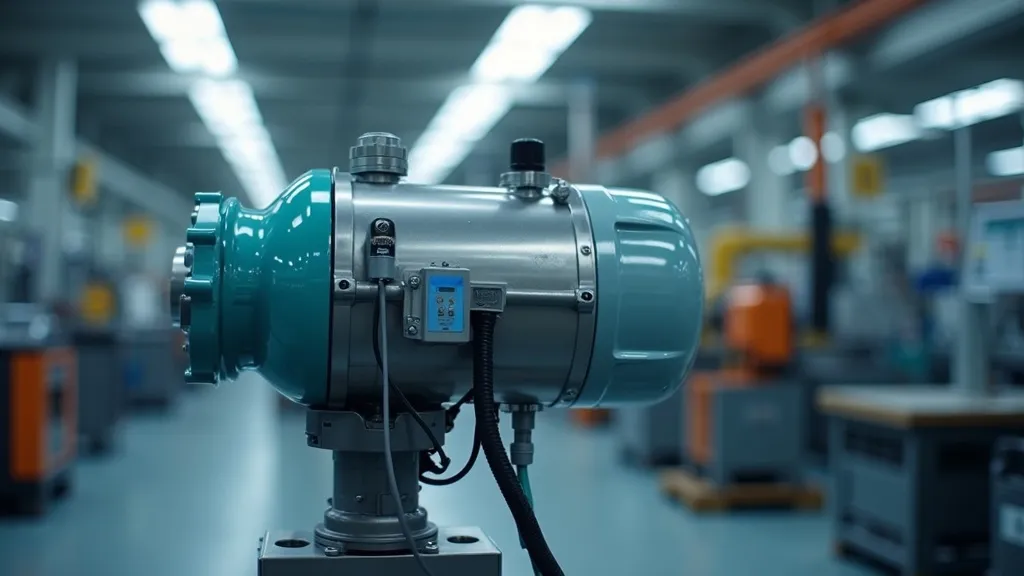

Parker pneumatic actuators are critical components in industrial automation, providing efficient motion control through compressed air. These actuators are renowned for their reliability, precision, and adaptability, making them indispensable in various sectors, including manufacturing, automotive, and aerospace. Their design ensures robust performance, optimizing operations and reducing energy consumption.

Pneumatic actuators are pivotal in the realm of industrial automation, providing precise motion control through the use of compressed air. Among the leading products in this category are Parker pneumatic actuators, known for their exceptional performance and reliability. These actuators are designed to convert energy in the form of compressed air into mechanical motion, which can be linear or rotary, depending on the application. The principle behind pneumatic actuators is relatively straightforward: when compressed air is introduced into the actuator, it exerts force on a diaphragm or piston, resulting in mechanical movement. This system is particularly advantageous in scenarios where rapid actuation and high force are required, making pneumatic actuators a go-to solution for various industries.

Parker pneumatic actuators offer numerous advantages over other types of actuators. Their primary benefit lies in their simplicity and durability. Unlike electric actuators, which rely on complex electronics, pneumatic actuators utilize a straightforward mechanism that involves fewer moving parts, reducing the risk of mechanical failure and extending the life span of the device. This simplicity also translates to ease of installation and maintenance, as fewer components typically lead to reduced complexity in servicing.

Furthermore, Parker actuators are known for their rapid response times, making them ideal for applications requiring quick and precise movements. The ability to achieve high-speed actuation without significant delay is crucial in fast-paced industrial settings, such as assembly lines or robotic applications. Moreover, they are capable of operating in a wide range of environmental conditions, from extreme temperatures to harsh industrial environments, without compromising performance. This versatility makes them suitable for sectors ranging from food processing to pharmaceuticals, where stringent hygiene and operational standards must be adhered to.

Another notable advantage of Parker pneumatic actuators is their energy efficiency. By optimizing air consumption through advanced design and sealing technologies, these actuators minimize waste and reduce overall operational costs. In industries where compressed air is a primary energy source, this feature can lead to significant cost savings and contribute to more sustainable practices.

Parker pneumatic actuators are utilized across a myriad of industries, each benefiting from their unique capabilities. In the manufacturing sector, these actuators are essential for automation processes, helping to streamline operations and increase productivity. Their ability to provide precise control is particularly beneficial in the assembly of complex components where accuracy is paramount. For instance, in electronic component assembly, where tiny parts must be placed with exacting precision, pneumatic actuators facilitate this process efficiently.

In the automotive industry, Parker actuators play a crucial role in the assembly line, ensuring each component is placed with precision. Components such as doors, hoods, and other parts are often moved and positioned using pneumatic systems, which provide the necessary force and speed while maintaining safety and reliability. Similarly, in the aerospace industry, these actuators are used in various control applications, where reliability and performance are critical. For example, they may be employed in the deployment of landing gear or in the operation of cargo doors on aircraft, where failure is not an option.

The food and beverage industry also benefits from the use of Parker pneumatic actuators, particularly in packaging and processing applications. These actuators ensure that products are filled, sealed, and labeled efficiently and hygienically. The ability of pneumatic systems to operate in environments that require cleanliness and compliance with health regulations makes them an optimal choice for these applications.

Moreover, in the pharmaceutical sector, where precision in dosage and timing is critical, Parker pneumatic actuators can be found in various machinery that requires exact movements for filling and packaging medications. Their reliability and speed contribute significantly to enhancing production rates while ensuring the accuracy needed in drug manufacturing.

In the realm of robotics, Parker pneumatic actuators are integral to the functionality of robotic arms and other automated systems. These actuators provide the necessary force to manipulate tools and components, facilitating tasks such as welding, painting, and assembly. The versatility of pneumatic actuators allows them to be integrated into various robotic applications, enhancing functionality and efficiency.

Parker pneumatic actuators are available in a variety of models, each designed to meet specific operational requirements. They feature a robust construction with materials that can withstand high pressures and temperatures, ensuring durability and longevity. The engineering behind these actuators incorporates advanced materials that not only resist wear and corrosion but also contribute to overall performance stability.

Additionally, these actuators are equipped with advanced sealing technologies to prevent leaks and ensure efficient operation. This is particularly important in applications where air loss can lead to decreased performance and increased operational costs. The design of Parker pneumatic actuators often includes features such as dual sealing systems and pressure compensation, which enhance their reliability in demanding environments.

The customization options available with Parker actuators are another notable feature. Whether it’s adjusting the stroke length or configuring the mounting options, these actuators can be tailored to fit the unique needs of any application. This adaptability allows users to modify the actuators based on their specific requirements, such as adjusting the speed of actuation or the force output. Furthermore, Parker provides options for integrating sensors and feedback mechanisms, which can enhance the overall control and monitoring of actuator performance. This level of customization is crucial in industries where unique challenges and requirements must be met.

| Model | Stroke Length | Operating Pressure | Temperature Range | Mounting Options | Body Material |

|---|---|---|---|---|---|

| Parker P1D | Up to 2000 mm | 1-10 bar | -20°C to +80°C | Multiple configurations available | Anodized aluminum |

| Parker P1F | Up to 1500 mm | 1-8 bar | -10°C to +60°C | Standard and custom options | Stainless steel |

| Parker P2S | Up to 3000 mm | 1-6 bar | -30°C to +70°C | ISO mounting patterns | Anodized aluminum |

| Parker P3M | Up to 1000 mm | 1-12 bar | -20°C to +80°C | Universal mounting | Composite material |

Q: How do Parker pneumatic actuators improve energy efficiency?

A: Parker pneumatic actuators are designed to optimize air consumption, utilizing advanced sealing technologies and precision engineering to minimize air loss and enhance energy efficiency. By ensuring that the actuators operate at peak performance and reducing unnecessary air usage, industries can significantly lower their operational costs and reduce their environmental footprint.

Q: What maintenance is required for Parker pneumatic actuators?

A: Regular maintenance involves checking for air leaks, ensuring all seals are intact, and verifying the correct operation of all moving parts. Parker provides detailed maintenance guidelines to ensure good reliability and performance. This includes periodic inspections of the actuator’s components, lubrication of moving parts, and replacement of worn-out seals to prevent leaks and maintain efficiency. Additionally, operators are encouraged to monitor the system for any unusual sounds or performance issues, which could indicate a need for immediate maintenance.

Q: Can Parker pneumatic actuators be used in hazardous environments?

A: Yes, Parker pneumatic actuators are designed to operate in a variety of environments, including those that are hazardous. However, it is crucial to select the appropriate model and configuration to match the specific environmental conditions. For instance, in environments with flammable gases or dust, actuators with special coatings and materials resistant to corrosion and ignition are recommended. Additionally, understanding the local regulations and safety standards is essential when deploying pneumatic actuators in such settings.

Q: What role do sensors play in enhancing the performance of pneumatic actuators?

A: Sensors can significantly enhance the performance of pneumatic actuators by providing real-time feedback on position, pressure, and speed. This information allows for better control and adjustment of the actuator’s operations, ensuring that it meets the precise requirements of a given application. Integrating sensors can also facilitate predictive maintenance, as operators can monitor the actuator’s performance and detect issues before they lead to failure. This proactive approach not only improves reliability but also extends the lifespan of the actuator.

As industries continue to evolve, the technology behind pneumatic actuators is also advancing. One of the most significant trends is the integration of smart technologies. With the rise of Industry 4.0, manufacturers are increasingly looking for ways to incorporate IoT (Internet of Things) capabilities into their equipment. This can include the integration of sensors and connectivity features that allow for remote monitoring and control of pneumatic actuators. Such advancements enable manufacturers to optimize their operations in real time, improving efficiency and reducing downtime.

Another trend is the development of more compact and lightweight actuator designs. As industries strive to reduce the size and weight of equipment without sacrificing performance, pneumatic actuator manufacturers are innovating to create products that meet these demands. This can lead to significant space savings in machinery design and better energy efficiency, contributing to overall operational effectiveness.

Moreover, advancements in materials science are also contributing to the development of more durable and efficient pneumatic actuators. New materials that offer increased resistance to wear, corrosion, and extreme environmental conditions are being explored, further enhancing the reliability and lifespan of these devices.

Additionally, sustainability is becoming an essential consideration in the design and manufacturing of pneumatic actuators. Manufacturers are increasingly focusing on creating products that are not only efficient but also environmentally friendly. This includes using recyclable materials and minimizing waste during the production process. As regulatory pressures and consumer expectations regarding sustainability continue to rise, pneumatic actuator manufacturers will need to adapt and innovate to meet these challenges.

In conclusion, Parker pneumatic actuators are integral components in the automation industry, offering unmatched reliability, precision, and adaptability. Their ability to operate effectively in diverse conditions and applications makes them a preferred choice for industries aiming to enhance efficiency and productivity. As technology advances, Parker continues to innovate, ensuring their pneumatic actuators remain at the forefront of industrial automation solutions. The combination of advanced engineering, robust construction, and a commitment to customer satisfaction positions Parker as a leader in the field of pneumatic actuation. As industries continue to evolve and adopt new technologies, the role of pneumatic actuators will undoubtedly grow, paving the way for more efficient and sustainable manufacturing practices.

Ultimately, the future of pneumatic actuators, particularly those from Parker, appears bright. With ongoing developments in smart technology, material science, and sustainability, these devices are poised to meet the challenges of tomorrow's industrial landscape while continuing to deliver the performance and reliability that users have come to expect.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!