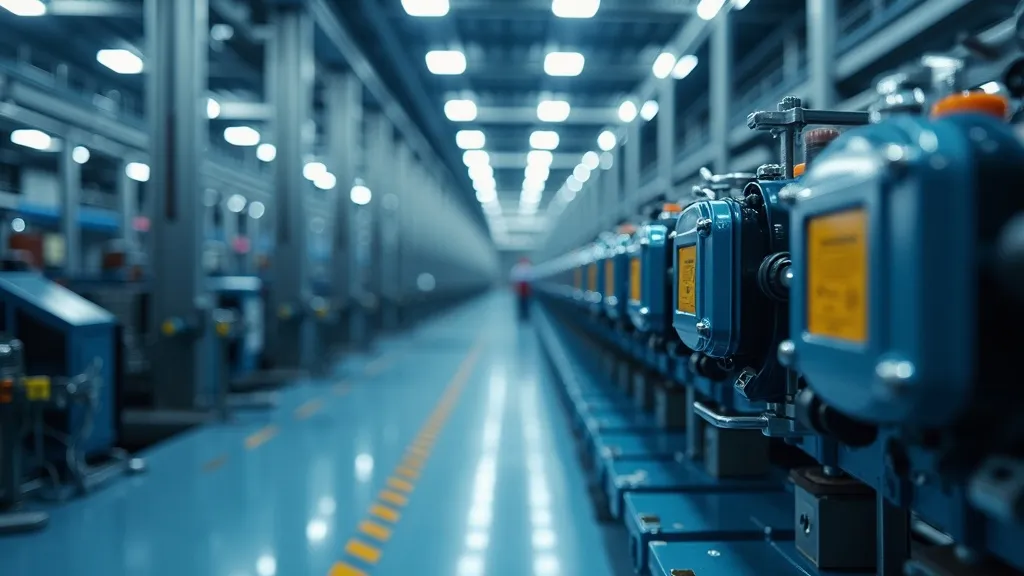

Parker Pneumatic Actuators are crucial components in industrial automation, converting energy into motion with precision. These actuators are known for their reliability, efficiency, and adaptability in various applications. This article explores their functionality, benefits, and applications, providing a detailed insight into their role in modern industry.

Introduction to Parker Pneumatic Actuators

Parker Pneumatic Actuators play a pivotal role in the realm of industrial automation by converting compressed air energy into mechanical motion. This transformation is essential for driving various mechanical operations, making these actuators indispensable in numerous industrial applications. Known for their precision and reliability, Parker Pneumatic Actuators have become a trusted choice for industries aiming to enhance operational efficiency and performance. The technology behind these actuators is built on years of innovation and engineering excellence, ensuring they remain at the forefront of automation solutions.

What Sets Parker Pneumatic Actuators Apart?

The distinguishing feature of Parker Pneumatic Actuators lies in their robust design and adaptability. Engineered to withstand harsh industrial environments, these actuators offer long-lasting performance with minimal maintenance. Their high efficiency is complemented by a wide range of configurations, allowing for flexibility in integration with various systems. This adaptability ensures that industries can tailor solutions to meet specific operational needs without compromising on performance. Furthermore, Parker's commitment to continuous improvement and customer feedback has driven the evolution of their pneumatic actuator technology, ensuring they remain relevant in an ever-changing market.

Key Features and Benefits

Parker Pneumatic Actuators offer several key benefits that make them a preferred choice in the industry:

- Reliability: Built with durable materials, these actuators are designed to handle high-pressure environments, ensuring continuous operation without frequent breakdowns. Their construction includes corrosion-resistant components, making them suitable for use in demanding environments such as chemical processing and metal fabrication.

- Efficiency: Their design optimizes air consumption, reducing energy costs and enhancing overall system efficiency. Parker Pneumatic Actuators incorporate advanced sealing technologies that minimize leakage, further improving their efficiency.

- Versatility: Available in various sizes and configurations, they can be customized to suit different applications, from simple linear motion tasks to complex automation processes. This versatility extends to compatibility with a wide range of control systems, including PLCs and remote monitoring solutions.

- Ease of Maintenance: With straightforward maintenance requirements, operational downtime is minimized, leading to cost savings over time. Parker provides comprehensive maintenance guides and support, ensuring users can easily carry out routine checks and repairs.

Applications of Parker Pneumatic Actuators

Parker Pneumatic Actuators are utilized in a variety of industries, each leveraging their unique capabilities to improve operations:

- Manufacturing: In assembly lines, these actuators facilitate precise control of machinery, contributing to improved production efficiency and product quality. Applications include robotic assembly, material handling, and packaging systems where accuracy is paramount.

- Automotive: They are integral in automotive manufacturing processes, offering reliable operations essential for tasks like stamping and welding. In car assembly, for example, Parker actuators enable the automation of repetitive tasks, enhancing the speed and precision of production.

- Food and Beverage: The food processing industry benefits from their hygienic designs, ensuring compliance with health standards while maintaining efficient operations. These actuators can be used in bottling, packaging, and processing equipment, where cleanliness and efficiency are critical.

- Pharmaceuticals: In pharmaceutical manufacturing, these actuators ensure precise control necessary for maintaining the integrity of sensitive processes. Their ability to work in sterile environments makes them ideal for applications like filling and capping bottles in cleanroom conditions.

- Aerospace: The aerospace industry utilizes Parker Pneumatic Actuators for applications involving precise control and actuation in assembly lines, as well as in testing environments where reliability and performance are crucial.

- Mining and Construction: In these sectors, pneumatic actuators are used for controlling equipment and machinery that operate in rugged conditions, ensuring operational efficiency even in extreme environments.

Comparison Table: Parker Pneumatic Actuators vs. Competitors

| Feature |

Parker Pneumatic Actuators |

Competitors |

| Durability |

High, with robust construction |

Variable, depending on brand |

| Efficiency |

Optimized for low air consumption |

May require more energy |

| Customization |

Highly customizable |

Limited customization options |

| Maintenance |

Easy and cost-effective |

Can be complex and costly |

| Technology Integration |

Compatible with modern control systems |

May lack advanced integration features |

| Technical Support |

Comprehensive support and resources |

Varies by manufacturer |

FAQs

- What industries benefit the most from Parker Pneumatic Actuators?

Parker Pneumatic Actuators are versatile and benefit a wide range of industries including manufacturing, automotive, food and beverage, pharmaceuticals, aerospace, and mining.

- How do Parker Pneumatic Actuators improve efficiency?

These actuators are designed to minimize air consumption, thus reducing energy costs and enhancing overall operational efficiency. Their advanced designs also ensure that they can operate effectively at varying pressures, allowing for consistent performance across different applications.

- Are Parker Pneumatic Actuators customizable?

Yes, they come in various sizes and configurations, allowing them to be tailored to specific industrial needs. Parker also offers engineering support to help clients design the most effective actuator solution for their particular application.

- What is the maintenance requirement for these actuators?

They require minimal maintenance, which helps reduce operational downtime and associated costs. Users are encouraged to perform regular inspections and replace wear components as needed to ensure optimal performance.

- Can Parker Pneumatic Actuators be integrated with modern automation systems?

Absolutely. Parker Pneumatic Actuators are designed with compatibility in mind, making them easy to integrate with various control systems, sensors, and monitoring technologies.

Conclusion

Parker Pneumatic Actuators stand out in the industrial automation sector due to their superior design, efficiency, and adaptability. Their ability to provide reliable and precise mechanical motion makes them invaluable in a wide array of applications. As industries continue to seek solutions that enhance productivity and reduce costs, Parker Pneumatic Actuators offer a compelling option that meets these demands effectively. Furthermore, with ongoing advancements in pneumatic technology and a commitment to innovation, Parker continues to lead the way in providing cutting-edge solutions that meet the evolving needs of the industrial landscape.

Advanced Technologies in Parker Pneumatic Actuators

The innovation behind Parker Pneumatic Actuators goes beyond basic functionality; it encompasses advanced technologies that enhance their performance and versatility. These technologies include:

- Smart Sensors: Many Parker actuators are equipped with integrated sensors that provide real-time feedback on actuator position and performance. This data can be used to optimize operations, improve accuracy, and prevent potential failures.

- Modular Design: The modular design of Parker Pneumatic Actuators allows for easy upgrades and customization. Users can add or remove components to adapt the actuator to changing operational needs without requiring a complete replacement.

- Eco-Friendly Options: Parker has developed eco-friendly pneumatic actuators that utilize sustainable materials and energy-efficient designs. These options help companies reduce their environmental footprint while maintaining high performance.

- Advanced Coatings: The use of advanced coatings on actuator components enhances their resistance to wear, corrosion, and other environmental factors, extending the lifespan of the actuator in harsh conditions.

Understanding the Mechanics of Parker Pneumatic Actuators

To fully appreciate the capabilities of Parker Pneumatic Actuators, it is essential to understand their mechanical workings. These actuators operate on the principle of converting pneumatic energy into mechanical energy through a series of components:

- Piston: The heart of the actuator, the piston moves in response to the pressure of the incoming compressed air. The design of the piston and cylinder ensures efficient movement and minimal friction.

- Seals: Seals are critical for maintaining pressure within the actuator and preventing air leakage. Parker uses advanced sealing technologies that ensure long-lasting performance and reliability.

- Mounting Options: Parker Pneumatic Actuators come with various mounting options, including flange, foot, and pivot mounts, providing flexibility in installation and integration with existing systems.

- Control Mechanisms: Integrated control mechanisms, such as limit switches and position sensors, allow for precise control over the actuator's motion, enabling seamless integration with automated systems.

Parker Pneumatic Actuators in the Future of Automation

As industries evolve, the demand for automation solutions that are not only efficient but also adaptable to new technologies is paramount. Parker Pneumatic Actuators are positioned to play a significant role in this future. With the rise of Industry 4.0, the integration of IoT (Internet of Things) technologies is becoming increasingly important. Parker is investing in research and development to enhance the connectivity of their actuators, enabling them to communicate with other devices and systems in real-time.

Moreover, as industries strive for greater sustainability, Parker is committed to developing actuators that consume less energy and generate less waste. This commitment to sustainability aligns with global trends towards greener manufacturing practices, ensuring that Parker Pneumatic Actuators remain a relevant and responsible choice for forward-thinking companies.

Case Studies: Success Stories with Parker Pneumatic Actuators

Real-world applications of Parker Pneumatic Actuators highlight their capabilities and the benefits they bring to diverse industries. Here are a few notable case studies:

- Automotive Assembly Line Efficiency: A leading automotive manufacturer implemented Parker Pneumatic Actuators in their assembly line to automate the installation of components. The result was a 30% increase in production efficiency, along with a significant reduction in manual labor costs.

- Food Processing Hygiene Standards: A food processing facility adopted Parker actuators for their packaging lines, ensuring compliance with stringent hygiene standards. The actuators' easy-to-clean design and reliability led to a smoother production process and improved product safety.

- Pharmaceutical Precision in Manufacturing: A pharmaceutical company utilized Parker Pneumatic Actuators in their bottling and labeling processes. The actuators provided the necessary precision to handle sensitive materials, resulting in zero contamination incidents and higher overall product quality.

Conclusion: The Future of Parker Pneumatic Actuators

Parker Pneumatic Actuators are not just a product; they are a critical component of modern industrial automation strategies. Their robust design, advanced technologies, and adaptability to various applications make them an essential tool for enhancing operational efficiency and productivity. As industries continue to evolve and embrace new technologies, Parker is poised to lead the way in providing innovative solutions that meet the challenges of tomorrow. With a strong commitment to quality, sustainability, and customer satisfaction, Parker Pneumatic Actuators will remain a key player in the automation landscape for years to come.