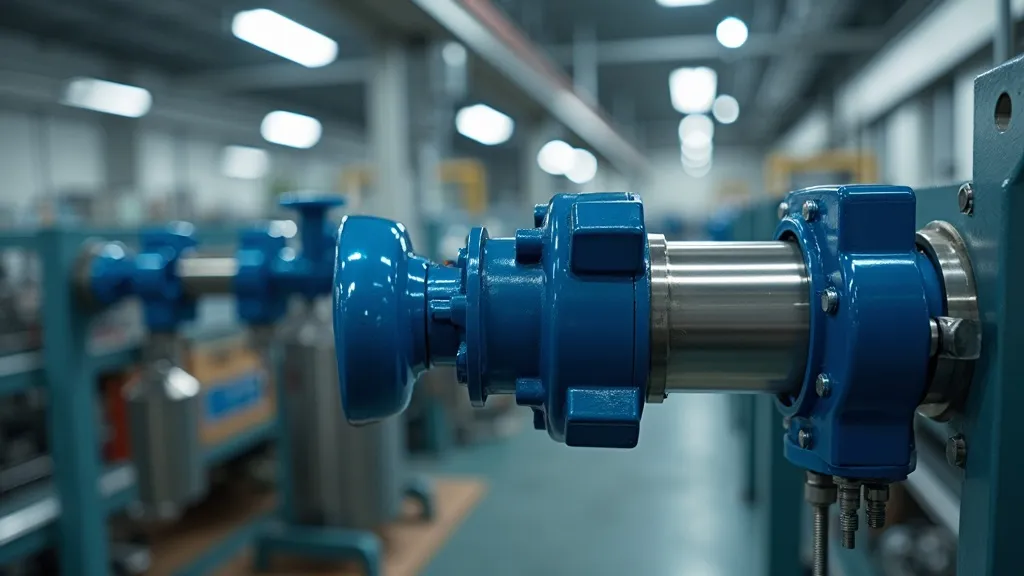

Parker pneumatic actuators are essential components in the automation industry, providing reliable motion control. These actuators convert energy into mechanical motion, enabling precise control in various applications. This article explores the features, benefits, and applications of Parker pneumatic actuators, offering insights into their industry significance and operational efficiency.

The modern automation industry heavily relies on advanced solutions for motion control, with Parker pneumatic actuators standing out as a pivotal component. These actuators are designed to convert compressed air into mechanical motion, which is crucial for operating valves and other industrial machinery. Known for their reliability and efficiency, Parker pneumatic actuators are integral to numerous applications across various sectors, including manufacturing, automotive, and aerospace. As industries strive for greater efficiency and productivity, the demand for advanced pneumatic solutions continues to rise, positioning Parker as a leader in the field.

Pneumatic actuators work by converting energy stored in compressed air into motion. This process involves several key components, including a cylinder, piston, and control valves. When air pressure is applied to the piston, it moves within the cylinder, producing linear or rotary motion. This straightforward yet effective mechanism allows for precise control of industrial processes, making pneumatic actuators indispensable in automation.

The operation begins with the compressor generating compressed air, which is then directed to the actuator through a series of control valves. The control valves regulate the flow of air into the cylinder, allowing the piston to move back and forth or rotate, depending on the actuator's design. The selection of materials and the design of these components play a crucial role in their performance, influencing factors such as speed, force, and response time.

Moreover, pneumatic actuators can be categorized into different types, including single-acting and double-acting actuators. Single-acting actuators use compressed air to move the piston in one direction, relying on a spring return mechanism to return the piston to its original position. On the other hand, double-acting actuators use compressed air to control movement in both directions, offering greater flexibility and control in applications where precise positioning is required.

Parker pneumatic actuators offer a range of features that enhance their performance and utility:

The versatility of Parker pneumatic actuators makes them suitable for a wide range of applications:

| Feature | Benefit |

|---|---|

| High-Quality Construction | Ensures durability and longevity in demanding environments. |

| Precise Motion Control | Facilitates accurate and reliable automation processes. |

| Custom Configurations | Ability to tailor specifications to specific industrial needs. |

| Energy Efficiency | Reduces operational energy consumption and costs. |

| Low Maintenance Requirements | Minimizes downtime and maintenance costs over the actuator's lifecycle. |

| Safety Features | Enhances operational safety in critical applications. |

As technology evolves, so too does the design and functionality of pneumatic actuators. Parker is at the forefront of integrating advanced technologies into their pneumatic actuator systems. One such innovation is the incorporation of smart sensors, which allow for real-time monitoring of actuator performance and status. These sensors can detect variations in pressure, temperature, and position, providing valuable data for system optimization.

Additionally, the use of IoT (Internet of Things) technology enables Parker actuators to communicate with other devices and systems, facilitating a more interconnected and efficient automation process. For instance, data collected from pneumatic actuators can be analyzed to predict maintenance needs, reducing the risk of unexpected failures and enhancing overall system reliability.

Moreover, advancements in materials science have led to the development of lighter and more durable materials for actuator construction. This not only reduces the overall weight of pneumatic systems but also enhances their resistance to wear and environmental factors, further extending their operational lifespan.

The future of pneumatic actuators is promising, with several trends likely to shape their development and application. One significant trend is the increasing demand for automation in industries where it was previously limited. As companies look to improve productivity and reduce labor costs, the role of pneumatic actuators in these sectors will expand.

Additionally, the push for sustainability and energy efficiency is prompting manufacturers to seek out pneumatic solutions that minimize energy consumption and waste. Parker is committed to developing actuators that not only meet performance standards but also align with environmental goals.

Furthermore, the integration of artificial intelligence (AI) into automation systems is expected to enhance the capabilities of pneumatic actuators. AI can optimize actuator performance by analyzing vast amounts of data, allowing for predictive maintenance and improved operational efficiency. This level of intelligence in pneumatic systems will lead to significant advancements in how industries approach automation.

Parker pneumatic actuators represent a cornerstone of modern automation technology, offering unmatched reliability, precision, and energy efficiency. Their adaptability across various industries makes them a preferred choice for engineers and manufacturers seeking to optimize their systems. As automation continues to advance, the role of pneumatic actuators like those from Parker is set to grow, driving innovation and efficiency in industrial processes worldwide.

In summary, the ongoing development of advanced materials, integration of smart technologies, and the trend towards greater automation signal a bright future for Parker pneumatic actuators. As these technologies evolve, they will not only enhance operational efficiency but also contribute to more sustainable industrial practices. Organizations looking to remain competitive in their respective fields will undoubtedly turn to Parker pneumatic actuators as a reliable and efficient solution for their automation needs.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!