This article delves into the intricate world of Parker pneumatic actuators, essential components in modern automation systems. Pneumatic actuators use compressed air to produce mechanical motion, making them integral to various industries. Parker is a renowned name in this field, known for its innovative designs and reliable products. This guide explores their functionality, applications, and industry impact.

Pneumatic actuators are pivotal in the automation industry, serving as the critical component that converts compressed air into mechanical motion. Among the leading names in this sector, Parker stands out due to its commitment to quality and innovation. Understanding the nuances of Parker pneumatic actuators can provide valuable insights into their role in enhancing industrial efficiency. As industries continuously strive for improved productivity, the significance of reliable actuators becomes more pronounced. Furthermore, the field of automation is rapidly evolving, and pneumatic actuators must adapt to meet these changes. In this context, the exploration of Parker pneumatic actuators reveals not only their fundamental functionalities but also their impact on various industries.

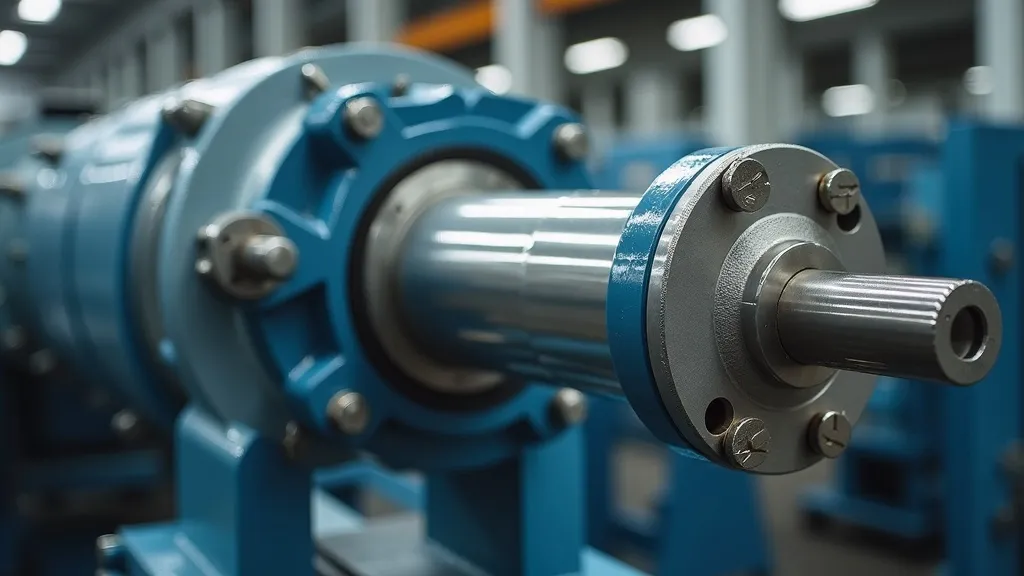

Parker pneumatic actuators operate by converting energy from compressed air into mechanical motion, which can be linear or rotary. This conversion is achieved through the actuator's internal components, which manage the air pressure and translate it into the desired movement. The simplicity of this mechanism, combined with Parker's precision engineering, ensures high performance and reliability across various applications. For instance, in a linear actuator, air pressure drives a piston within a cylinder, pushing the piston rod to create motion. In contrast, rotary actuators utilize the force of compressed air to turn a shaft, providing rotational movement. This versatility makes Parker pneumatic actuators suitable for a wide range of applications, from opening and closing valves to driving conveyor systems.

Moreover, the efficiency of pneumatic actuators is enhanced by their rapid response times and the ability to generate high forces relative to their size. Unlike electric actuators, which can suffer from issues related to overheating and slower response times, pneumatic actuators can operate continuously without significant performance degradation. This characteristic is particularly beneficial in high-demand environments where consistent operation is crucial.

Pneumatic actuators from Parker find applications in numerous sectors, including manufacturing, transportation, and energy. Their ability to deliver consistent force and motion makes them ideal for tasks such as controlling valves, operating machinery, and automating processes. Industries rely on these actuators for tasks that demand durability and precision, underscoring the importance of Parker's contributions to the field. In manufacturing, for example, pneumatic actuators are integral to assembly lines, where they facilitate the automation of repetitive tasks, thereby increasing efficiency and reducing labor costs.

In the transportation sector, pneumatic actuators are employed in systems that require precise control, such as in aircraft landing gear mechanisms and car seat adjustments. They provide the necessary force to actuate these systems quickly and reliably, essential for safety and operational effectiveness. The energy sector also benefits from pneumatic actuators, particularly in controlling valves in pipelines and other critical infrastructure, where reliable operation is paramount to ensuring safety and efficiency.

Additionally, the versatility of Parker pneumatic actuators means they can be used in specialized applications, such as robotics and medical devices. In robotics, pneumatic actuators can mimic natural movements, providing fluid motion that enhances the robot's capabilities. In medical devices, they can control various functions with high precision, contributing to advancements in healthcare technology.

Parker's reputation in the pneumatic actuator market is built on its innovative designs and commitment to quality. The company's actuators are engineered to withstand harsh environments and rigorous operational demands, offering longevity and minimal maintenance needs. Additionally, Parker's focus on customer satisfaction ensures that their products are both reliable and suited to the specific needs of diverse industries. This dedication to quality is evident in the materials used, the engineering processes, and the testing protocols that Parker employs to ensure that each actuator meets stringent performance standards.

The benefits of choosing Parker pneumatic actuators extend beyond their immediate functionality. Parker’s global presence and extensive distribution network mean that customers can access support and replacement parts easily, minimizing downtime in operations. Furthermore, Parker invests in research and development, continuously seeking to innovate and improve their product offerings. This proactive approach to innovation ensures that Parker remains at the forefront of the pneumatic actuator industry.

| Feature | Benefit |

|---|---|

| Precision Engineering | Ensures accuracy and reliability in operations. |

| Durable Materials | Withstands harsh environments and reduces maintenance. |

| Wide Application Range | Suitable for multiple industries, enhancing versatility. |

| Global Support Network | Ensures easy access to services and replacement parts. |

| Innovative Design | Incorporates the latest technology for enhanced performance. |

Parker pneumatic actuators are a testament to the advancements in automation technology, providing essential solutions that meet the rigorous demands of modern industries. Their role in enhancing operational efficiency and productivity cannot be overstated, making them a critical component in the world of industrial automation. Whether you are involved in manufacturing, energy, or transportation, understanding the benefits and applications of these actuators can significantly impact your operations. As industries evolve and the need for automation increases, the reliability and functionality of Parker pneumatic actuators will continue to play a vital role in shaping the future of automation technology.

As we look to the future, pneumatic actuators are poised to undergo several advancements that will further enhance their functionality and applicability in various industries. With the growing emphasis on sustainability and energy efficiency, manufacturers, including Parker, are investing in technologies that reduce energy consumption while maintaining performance. Innovations such as energy-efficient designs, reduced air consumption, and improved materials are becoming increasingly prevalent.

Additionally, the integration of smart technologies into pneumatic actuators is an exciting development on the horizon. The use of IoT (Internet of Things) technology will allow for real-time monitoring and control of pneumatic systems, improving predictive maintenance and troubleshooting capabilities. This advancement not only enhances operational efficiency but also reduces downtime and increases the overall reliability of pneumatic systems.

Furthermore, as automation continues to permeate various sectors, the demand for compact and lightweight pneumatic actuators is expected to rise. These actuators will need to deliver high performance without compromising on size, enabling their integration into smaller and more complex systems, such as robotic applications and advanced manufacturing processes.

While pneumatic actuators offer numerous advantages, there are also challenges and considerations that users must keep in mind. One significant challenge is the requirement for a clean, dry air supply. Contaminants in the compressed air can lead to wear and tear on the actuator's internal components, potentially resulting in failure. Therefore, implementing proper air filtration and drying systems is crucial to ensure the longevity of pneumatic actuators.

Another consideration is the energy cost associated with operating pneumatic systems. While these systems can be very efficient, the cost of compressed air can be significant, especially in large-scale applications. Organizations must evaluate the overall cost-effectiveness of pneumatic actuators compared to other actuation methods, such as electric or hydraulic systems, to determine the best fit for their specific needs.

Moreover, the noise generated by pneumatic systems can be a concern in certain environments. Efforts to mitigate noise through soundproofing materials or quieter actuator designs are essential, particularly in settings where noise levels must be controlled, such as in food processing or healthcare facilities.

Parker pneumatic actuators represent not only a reliable choice for automation needs but also a forward-thinking approach to industrial challenges. As technology continues to evolve, Parker's commitment to innovation and quality ensures that their pneumatic actuators will remain a cornerstone in the automation industry. By understanding both the advantages and challenges associated with pneumatic actuators, businesses can make informed decisions about their automation strategies, paving the way for increased efficiency and productivity in their operations. Embracing these advanced technologies will ultimately contribute to a more sustainable and efficient industrial future.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!