Parker Pneumatic Actuators are pivotal components in the automation and control sectors, offering efficiency and precision. These actuators leverage compressed air to facilitate movement in various applications. Known for their reliability, they play a crucial role in industries ranging from manufacturing to aerospace, underscoring their versatility and importance in modern industrial processes.

Parker Pneumatic Actuators are integral to modern automation systems, providing the necessary motion control in numerous industrial applications. These devices utilize compressed air to produce mechanical motion, offering a reliable and efficient alternative to electric or hydraulic systems. Recognized for their durability and precision, Parker Pneumatic Actuators find applications across various industries, including manufacturing, aerospace, and automotive. The versatility of these actuators not only enhances their functionality but also enables them to adapt to the ever-changing demands of technology and process optimization.

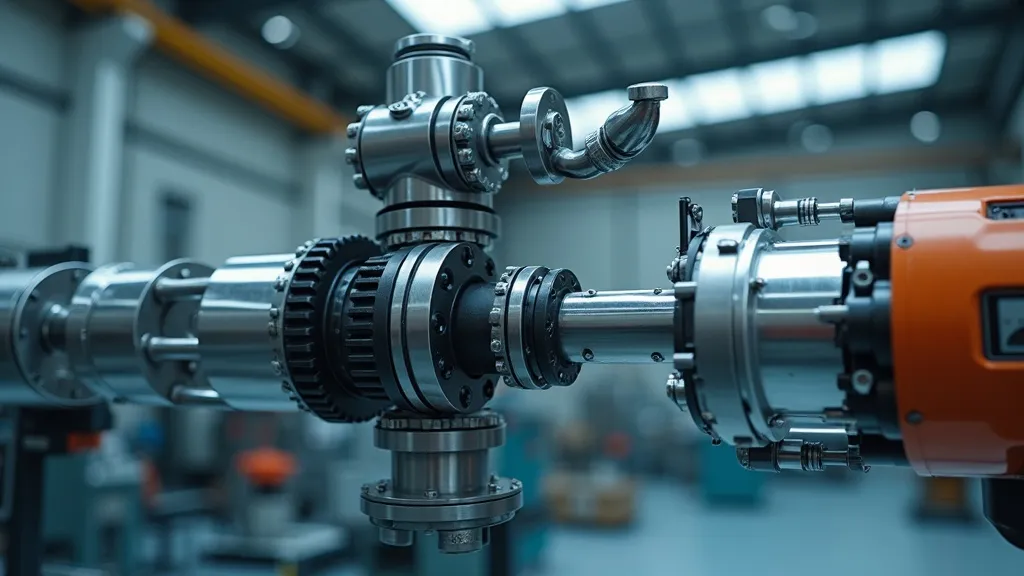

At the core of a pneumatic actuator's operation is the conversion of energy from compressed air into mechanical motion. This process involves several components, such as a piston, cylinder, and valves, which work together to create linear or rotary motion. The advantages of using pneumatic systems include their simplicity, speed, and ability to operate in hazardous environments where electrical systems might pose a risk.

The basic operation of a pneumatic actuator can be understood through its components. The actuator consists of a cylinder that houses a piston. When compressed air enters the cylinder, it pushes the piston, creating motion. Depending on the configuration, the actuator can produce either linear or rotary motion. Linear actuators extend and retract along a straight path, while rotary actuators provide a rotational movement around an axis. This flexibility allows for a wide variety of applications, from simple tasks like opening and closing valves to complex movements in robotic arms.

Moreover, pneumatic actuators are equipped with various control valves that regulate the flow of air into the cylinder. This control is critical for adjusting the speed and force of the actuator, enabling precise movements and operations. Additionally, these systems can be integrated with sensors and controllers, allowing for automated processes that enhance efficiency and accuracy in industrial environments.

Pneumatic actuators are widely used in applications that require rapid and repeatable motion. In the manufacturing sector, they are essential for tasks such as assembly, material handling, and packaging. For instance, in assembly lines, pneumatic actuators can be employed to automate the placement of components, ensuring consistent quality and reducing the risk of human error. Similarly, in material handling, these actuators facilitate the movement of goods, streamlining operations and increasing throughput.

In the aerospace industry, these actuators ensure the precise control of aircraft systems, contributing to overall safety and performance. They are used in various applications, such as controlling flaps, landing gear, and other critical systems that require reliable and precise actuation. The ability to function effectively in extreme conditions, such as high altitudes and varying temperatures, makes pneumatic actuators particularly suitable for this industry.

Furthermore, the automotive industry relies on pneumatic actuators for applications like braking systems and engine controls. In braking systems, pneumatic actuators provide the necessary force for emergency braking and assist in controlling the brake pressure. In engine controls, they can manage air intake and exhaust processes, optimizing fuel efficiency and reducing emissions. The integration of pneumatic actuators in these systems not only enhances performance but also contributes to the overall safety of vehicles.

Other industries, such as food and beverage, pharmaceuticals, and energy, also utilize pneumatic actuators for various tasks. In food processing, for example, pneumatic actuators are used to control the flow of ingredients and automate packaging processes, ensuring hygiene and efficiency. In the pharmaceutical sector, they play a critical role in manufacturing and packaging medications, where precision and reliability are paramount. In energy production, they assist in the control of valves and other equipment, helping to maintain safety and efficiency in operations.

Parker Pneumatic Actuators are renowned for their robustness and efficiency. Their design allows for minimal maintenance, reducing downtime and operational costs. This is particularly important in industries where every second counts, as reduced maintenance translates to increased productivity. Additionally, they offer excellent control over force and speed, making them ideal for applications requiring precision. The versatility of these actuators also means they can be customized to fit specific application needs, further enhancing their appeal in various industries.

Another significant benefit of Parker Pneumatic Actuators is their adaptability to various environmental conditions. They can operate effectively in extreme temperatures and harsh environments, such as those found in outdoor installations or in the presence of corrosive substances. This durability extends the lifespan of the actuators, providing a reliable solution for companies seeking long-term performance without frequent replacements.

Furthermore, Parker Pneumatic Actuators are designed with safety in mind. They often include features such as pressure relief valves and safety interlocks, which help prevent accidents and ensure safe operation. This focus on safety is crucial in industries where the potential for hazards is high, and the reliability of equipment is non-negotiable.

The energy efficiency of pneumatic actuators is another noteworthy advantage. They typically consume less energy compared to electric actuators, particularly in applications requiring rapid motion. This efficiency not only reduces operational costs but also aligns with the growing emphasis on sustainability in industrial practices. By minimizing energy consumption, companies can lower their carbon footprint and contribute to more environmentally-friendly operations.

Moreover, the ease of integration with existing systems is a significant advantage of Parker Pneumatic Actuators. They can be easily incorporated into automated systems and controlled via various interface options, such as programmable logic controllers (PLCs) or human-machine interfaces (HMIs). This flexibility allows manufacturers to upgrade or modify their systems with minimal disruption, facilitating continuous improvement in processes.

| Type | Benefits | Applications |

|---|---|---|

| Linear Actuators | Simple design, reliable performance | Automotive, manufacturing |

| Rotary Actuators | Compact, high torque | Aerospace, robotics |

| Diaphragm Actuators | High efficiency, low maintenance | Food processing, pharmaceuticals |

| Double Acting Actuators | Greater control, versatility | Machinery automation, packaging |

This table illustrates the various types of pneumatic actuators available, highlighting their specific benefits and applications. Linear actuators, known for their straightforward design, are commonly found in manufacturing and automotive applications where reliability is crucial. In contrast, rotary actuators are compact and provide high torque, making them ideal for applications in aerospace and robotics, where space is often limited and precision is essential.

Diaphragm actuators are another type that has gained popularity, particularly in the food processing and pharmaceutical industries. Their design allows for high efficiency and minimal maintenance, which is a significant advantage in production environments where hygiene and operational efficiency are paramount. Lastly, double acting actuators provide greater control and versatility, making them suitable for various applications in machinery automation and packaging, where precise movements are necessary.

Parker Pneumatic Actuators stand out in the realm of motion control, offering unmatched reliability and efficiency. Their robust design, coupled with the ability to perform in challenging environments, makes them a preferred choice for many industries. As technology advances and industries continue to evolve, the demand for precise and durable automation solutions like Parker's will only grow, underscoring their critical role in modern industrial processes.

The future of pneumatic actuators appears promising, with ongoing innovations aimed at enhancing their performance and expanding their applications. Research into new materials and technologies is set to improve efficiency further, reduce environmental impact, and increase the versatility of pneumatic systems. As industries increasingly adopt automation and smart technologies, the integration of advanced pneumatic actuators will play a vital role in achieving greater efficiency and productivity.

In conclusion, Parker Pneumatic Actuators not only meet the current needs of industries but are also well-positioned to adapt to the future demands of automation and motion control. Their continued development will contribute significantly to advancements in various fields, making them an essential component in the machinery and equipment that drive modern manufacturing and industrial processes. As businesses seek to optimize their operations and improve safety, the reliance on high-quality pneumatic actuators, such as those offered by Parker, will only increase, solidifying their place in the landscape of industrial automation.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!